we explained in detail –What materials are needed for SMT patch processing.

Today, I will talk about the requirements, standards, and methods for selecting SMT assembly materials.

SMT patch processing plays a vital role in the manufacturing of electronic products, and its quality directly affects product performance and reliability.

Material selection is a crucial step in surface mount technology patch processing, and its requirements, standards, and methods directly affect the quality of the patch.

Material requirements

The materials used in SMT production mainly include the following categories:

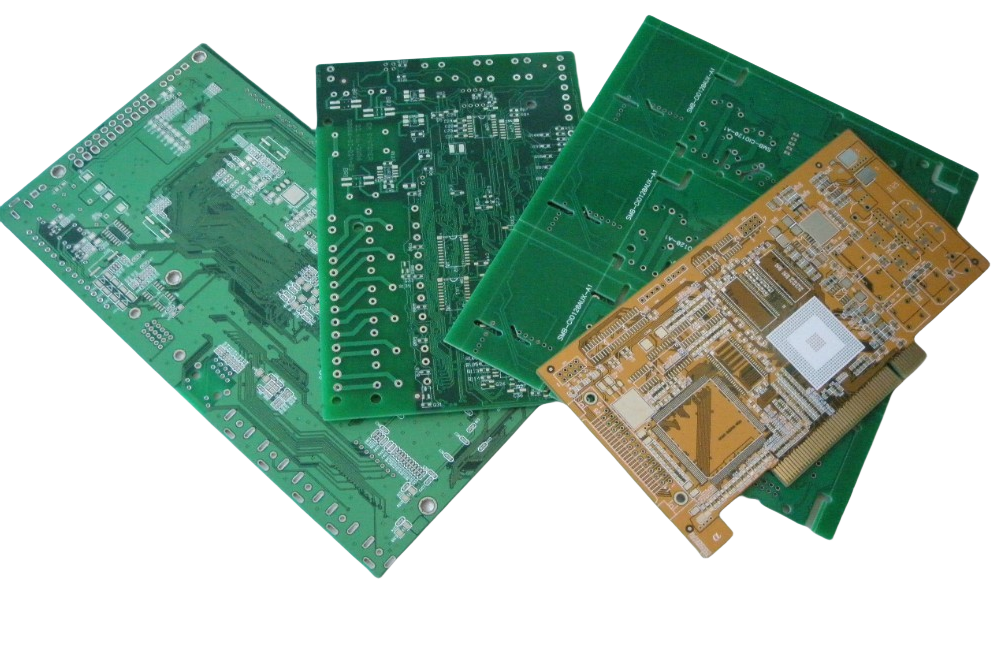

Printed Circuit Board (PCB): PCB as a carrier for SMT patch processing

material, thickness, board shape, and number of layers will directly affect the patch process and welding quality.

Components: The components used in SMT manufacturing include resistors, capacitors, diodes, transistors,ICs, etc.

Component quality, size, and pin spacing will also affect the SMT process and welding quality.

Solder paste: Solder paste is the welding material for SMT patch processing. Its composition, fluidity, viscosity, and other factors will affect the welding quality.

Flux: Flux is an auxiliary material in the welding process, and its composition, activity, and other factors will also affect the welding quality.

Material Standards

In order to ensure the material quality and reliability of SMT assembly, it is significant to formulate relevant standards.

Some common SMT patch processing material standards include:

IPC-A-610: Standardizes the design and manufacturing of printed circuit boards to ensure they meet quality requirements.

IPC-7351: Defines the design and manufacturing standards for surface mount components to ensure that the components meet the requirements of the patch process.

IPC-7151: Standardizes the design and manufacturing standards of the solder paste to ensure welding quality.

IPC-7326: Defines the design and manufacturing standards for solder flux to ensure quality meets the requirements.

Material selection method

The selection of SMT patch processing materials should be based on the specific requirements of the product, taking into account the following factors:

Product performance requirements: Select materials based on product performance requirements. For example, high-frequency products require PCBs and components with good high-frequency characteristics.

Product cost requirements: choosing the most economical material while meeting product performance requirements.

Availability of materials: Ensure a timely and stable supply of required materials to avoid PCB assembly delays.

Conclusion

Choosing SMT patch processing materials is a crucial step in ensuring the quality of the entire patch.

When selecting materials, we fully consider specific product requirements, balancing material performance, cost, and availability factors.

Scientifically and rationally selecting materials and complying with relevant standards can improve the quality level of SMT patch processing to ensure the performance and reliability of the final product.