1.Parts cost

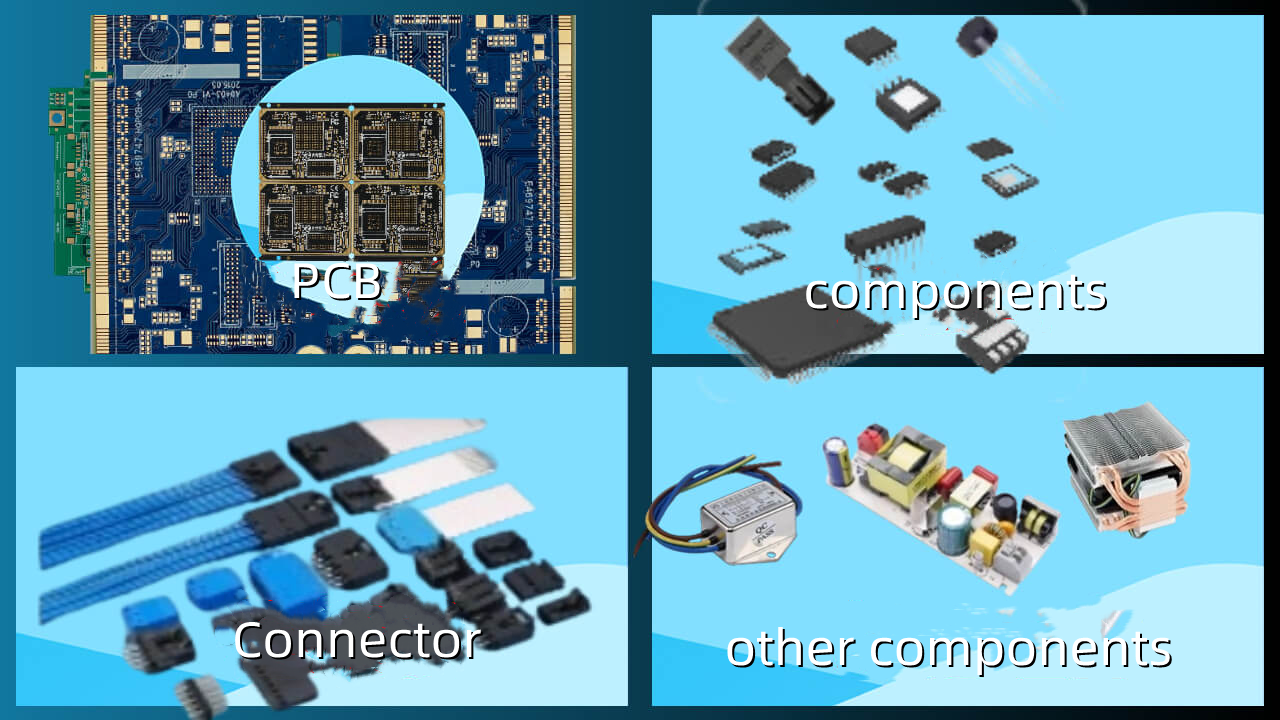

The main cost of SMT assembly is the price of SMT parts, including resistors, capacitors, IC chips, etc.

It is best to provide a BOM and related process requirements.

If it is a PCB copyboard, the BOM table may not be the main thing, and the functional description of the PCB clone needs to be as detailed as possible.

Sample pictures of copy boards with clear descriptions of picture details. Pictures include large photographs and renderings.

Prices vary by component type, packaging, brand, and purchasing channel.

SMT patch processors can provide electronic component sourcing services, or customers can purchase them themselves.

1) BOM

The BOM lists the name, model, package type, brand, and quantity of all components required for the project.

A complete BOM is the basis of SMT assembly processing.

Because it identifies the components that need to be purchased, Therefore, it is important to ensure the accuracy and completeness of the BOM to avoid delays and errors.

2) Process requirements

In addition to the BOM, process requirements are also key documents.

These requirements describe the part’s correct installation, positioning, and soldering to ensure product reliability and performance.

Process requirements usually include component placement coordinates, welding temperature requirements, soldering agent usage specifications, etc.

3) Special requirements for cupboard projects

Since it needs to copy the existing circuit board in the cupboard project, so the detailed information and special requirements become significant.

Functional descriptions: Provide as detailed a description of the function as possible.

A clear and comprehensive functional description will help ensure that the newly manufactured board will function consistently with the original.

Sample pictures: You can provide high-quality sample pictures, take them from different angles as much as possible, and ensure the clarity of the photograph.

It helps SMT processors better understand the appearance and component layout of the original circuit board.

Image Detail Description: Provide a detailed description of each component, including its model, location, package type, etc.

It helps ensure proper installation and welding.

Large picture and rendering: In addition to the specific photograph of the components, you can also provide large pictures and renderings of the entire circuit board.

SMT patch processors can better understand the overall structure and connections of the circuit board.

2.PCB complexity

The complexity of PCB affects the SMT assembly cost.

Multilayer boards, high-density component layouts, micro-packages, and complex circuit structures will increase the workload and difficulty of SMT processing, thus leading to higher costs.

3.Quantity

Production quantity is another crucial factor. It determines the cost of SMT patch processing.

Generally speaking, the price per point for SMT processing in high-volume production is lower because the fixed costs can be distributed to more components.

Small batch production or custom PCB incur higher per-point costs.

If you need PCB prototyping, you can use the lowest-price contracting form to estimate the processing price.

4.Technical requirements

There are special technical requirements, such as BGA (Ball Grid Array) packaging, precise positioning of ultra-micro components, or lead-free soldering processes.

BGA packaging requires a dedicated BGA hot air oven and precision automatic positioning equipment to ensure correct soldering.

Lead-free soldering processes are adopted. It needs special processing, including the use of lead-free soldering materials, which will increase costs.

If there is DIP post-welding, the price of DIP post-welding processing is usually charged per solder point or component.

These extra steps will increase the cost of SMT processing.

5.Quality requirements

High quality and reliability requirements will introduce additional quality control and testing.

For example, ICT and FCT usually require more time and labor costs, thus increasing the cost per point.

6.Packaging and shipping costs

The delivery area will also affect the price. The express delivery costs in different regions are different.

Especially for large quantities of SMT processing products, the packaging and transportation costs will also be distinct.

Summary

In summary, the price of each point in SMT patch processing is affected by multiple factors.

We demand to comprehensively consider the parts cost, PCB complexity, production quantity, technical requirements, quality requirements, packaging, and transportation.

When choosing an SMT processing supplier, we should clearly define the project specifications and requirements.

And fully communicate with the SMT processing factory to obtain an accurate quote, which will help ensure the project’s cost-effectiveness and successful completion.

If you need to get the price of SMT patch and DIP post-welding processing, Circuitcardassembly is at your service 24 hours a day. Contact us now or get a quote online.