Cold welding

It refers to a solder joint with insufficient wetting.

Features: Appearance is gray and dull. When observed under a microscope, the solder joints are granular.

The main reasons are improper setting reflow oven temperature curve, too fast oven speed, products placed too densely in the oven, solder paste deterioration, etc.

Solder bridging

It refers to two or more solder joints connected, resulting in a short circuit. The characteristic is that two pins are connected together.

The main reasons are solder paste printing bridging, collapse, etc.

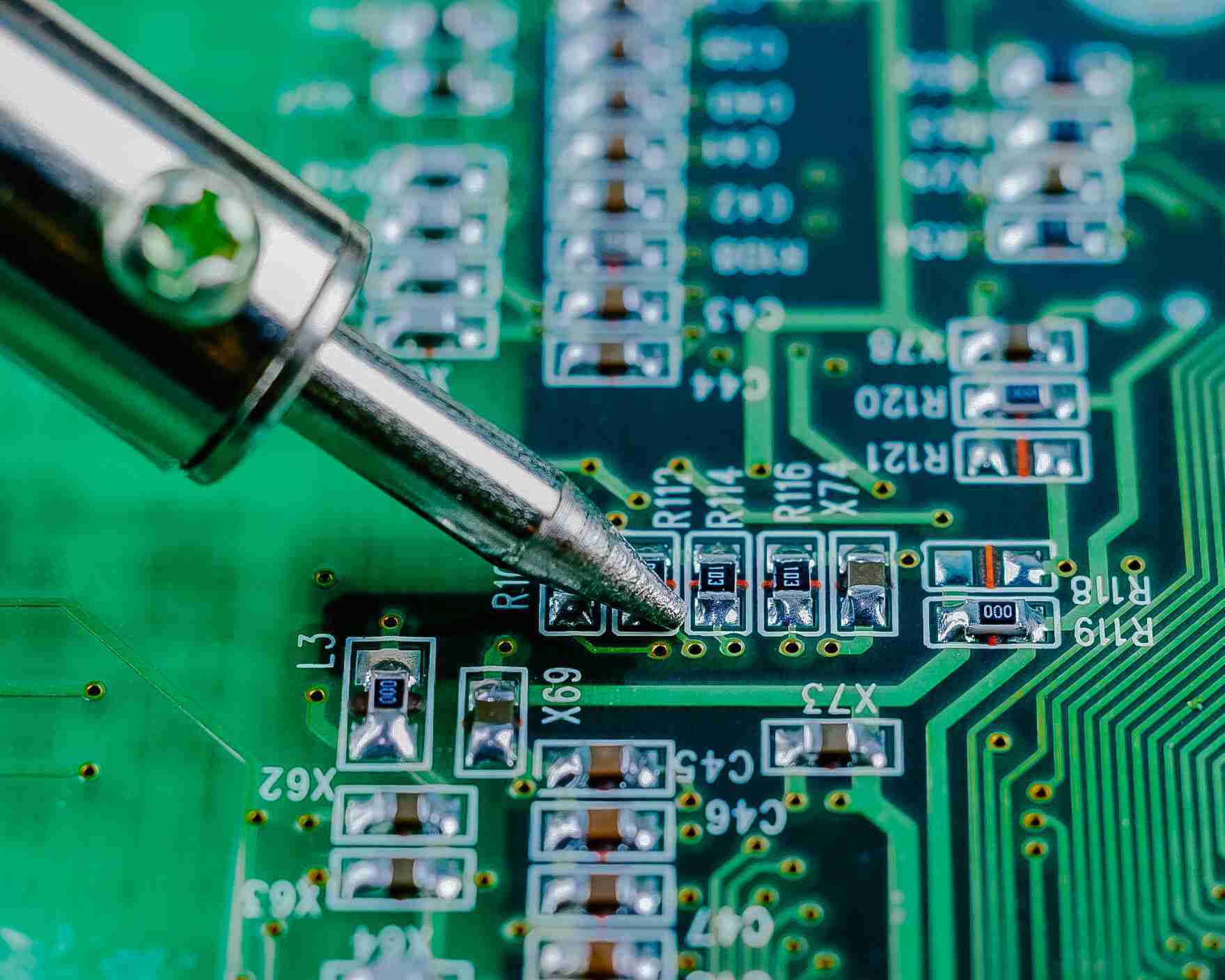

False soldering

It refers to the poor connection between component pins and PCB pads. This type of abnormality is most likely to occur in SMT soldering abnormalities.

Characteristics: The pin is not connected to the pad or wrapped in solder but not connected.

The main reasons are oxidation, deformation, contamination of component pins or pads, mismatch of design dimensions, printing and mounting offset, inconsistent furnace temperature settings, etc.

Standing piece

It is also called a tombstone.

Characteristics: One end of the component is not connected to the circuit and is warped.

Reasons: Improper product design leads to uneven heating at both ends of the component, horizontal plane deviation of the mounting surface, the pad or one end of the component pin being oxidized or contaminated, missing printing or printing offset of one end of the solder paste, etc.

Side Stand

Features: Although the components are soldered at both ends, the wide side of the components is vertical to the PCB.

The main reasons are loose component packaging, improper equipment debugging to flying parts, and wiping board during the furnace process.

Flip

Features: The silk screen side of the component originally facing upward is mounted to the bottom. This abnormality will not affect the realization of product functions, but it will affect maintenance.

The main reasons are loose component packaging, improper equipment debugging leading to flying parts, strong vibration of products during the furnace process, etc.

Solder beads

Characteristics: There are round solder balls in the non-welding area of the PCB.

The main reasons are that insufficient solder paste reheating time leads to rewetting, improper reflow temperature setting, improper steel mesh opening hole, etc.

Pinhole

Characteristics: Pinholes exist on the surface of solder joints. The main reasons are the rewetting of welding materials, improper reflow temperature, etc.