Printed Circuit Board Assembly (PCB Assembly) is a cornerstone of modern electronics, crucial to the functionality of almost every electronic device. Whether you’re reading this on a smartphone, a laptop, or a tablet, chances are, a PCB is at the heart of your device. This article delves deep into the fascinating world of PCB Assembly, breaking down complex concepts into easy-to-understand language for everyone. This guide has all the information you need, regardless of whether you’re new to the topic or want to review it.

1. Overview of PCB Assembly

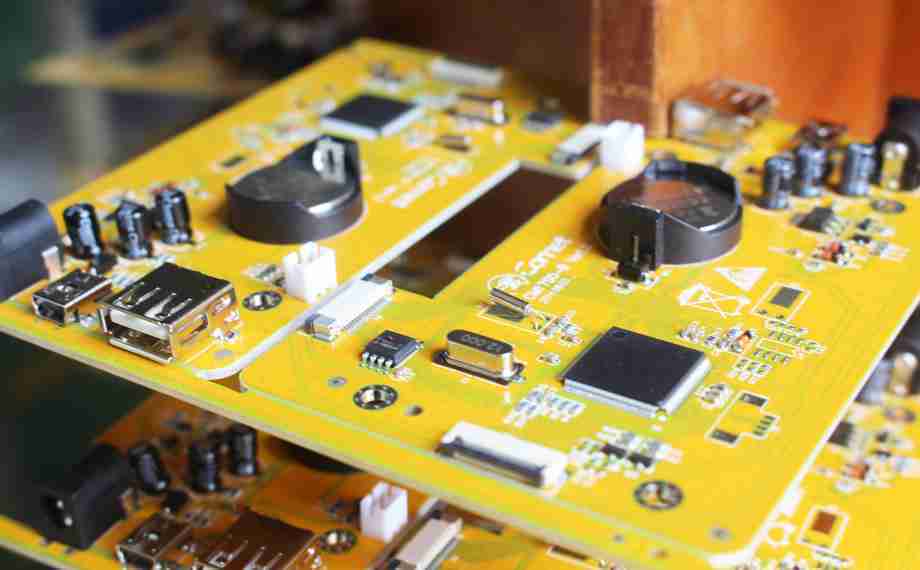

This process is integral to the manufacturing of electronic devices, making it essential for anyone interested in electronics to understand.

In simpler terms, if we think of a PCB as the skeleton of an electronic device, PCB Assembly is like adding the organs and muscles that make the device work. This process brings the bare bones of a circuit to life.

2. What is a Printed Circuit Board?

A Printed Circuit Board (PCB) is a level board produced using a non-conductive material that offers actual help and a pathway for electrical parts. These boards are typically made of fiberglass, composite epoxy, or other laminate materials.

How Do PCBs Work?

PCBs have pathways etched onto their surface, typically in the form of copper tracks, that connect various components like resistors, capacitors, and microchips. These pathways are the “streets” that guide electrical flows to various pieces of the board, permitting the gadget to carry out its planned role.

3. Types of PCB Assembly

There are several types of PCB assemblies, each suited for different applications. The decision of get together sort relies upon elements like the intricacy of the circuit, the size of the parts, and the planned utilization of the eventual outcome.

PCB assembly with a single side

In single-sided PCB assembly, components are attached to only one side of the board. This type of assembly is typically used for simpler, low-cost electronics like calculators or radios.

Double-Sided PCB Assembly

More intricate circuits can be built in a smaller area with double-sided printed circuit board assembly, which mounts components on both sides of the board. This type is common in consumer electronics like smartphones and laptops.

Multilayer PCB Assembly

Multilayer PCB Assembly consists of multiple layers of PCBs stacked on top of each other, with insulating layers in between. This type of assembly is used in high-performance electronics, such as servers and telecommunications equipment, where space and functionality are crucial.

4. Key Components of PCB Assembly

Several components play a critical role in PCB Assembly. Understanding these parts is fundamental for getting a handle on the intricacy and usefulness of the assembly cycle.

Resistors

Resistors are parts that control the progression of electrical flow by giving opposition. They are utilized to safeguard different parts and guarantee the legitimate working of the circuit.

Capacitors

Capacitors store and delivery electrical energy. They are crucial for smoothing out voltage fluctuations and providing power to various parts of the circuit.

Diodes

Diodes only permit current to travel in one direction, which blocks electrical impulses. They are used to protect circuits from potential damage.

Transistors

The fundamental components of contemporary electronics are transistors. They amplify or switch electrical signals, making them essential for the functioning of almost every electronic device.

Integrated Circuits (ICs)

An integrated circuit (IC) is a reduced electronic circuit made up of multiple components. ICs are utilized in basically all advanced electronic gadgets, from PCs to cell phones.

5. The PCB Assembly Process

There are a number of steps in the PCB Assembly process, and each one is important for making a circuit that works and is reliable. The most important steps are detailed below.

Circuit board design

The interaction starts with planning the PCB format utilizing particular programming. This plan incorporates the arrangement of parts, steering of pathways, and other basic subtleties.

Solder Paste Application

In this phase, solder paste is applied to the regions where the components will be installed. The paste is a combination of flux and small solder balls that helps in the soldering process.

Component Positioning

Component Positioning Following the application of the solder paste, components are positioned on the board. Automated machines that precisely position each component in accordance with the design are typically used to complete this step.

Reflow Soldering

Reflow Soldering After placing the parts, the board is placed in a reflow oven where the paste melts and bonds the parts to the board.

Inspection and Testing

The collected PCB goes through review and testing to guarantee that all parts are accurately positioned and that the circuit capabilities as planned.

6. SMT

Components can be mounted directly onto the PCB surface using Surface Mount Technology (SMT) as an alternative to being inserted through holes. Surface Mount Technology (SMT) Due to its efficiency and capacity to handle small components, SMT is the most common method utilized in contemporary PCB assembly.

Advantages of SMT

• Reduced Plan: SMT considers more parts to be set in a more modest region, prompting minimal and lightweight plans.

• Assembly by Automation: The SMT process is highly automated, which speeds up production and reduces the likelihood of human error.

• Economical: SMT is frequently more cost-effective than other assembly methods due to its efficiency.

7. Through-Hole Technology (THT)

An older method for assembling PCBs is through-hole technology (THT), in which components are soldered from the opposite side of the board after being inserted into holes drilled in the board.

THT is still used in some applications where mechanical strength is important, despite the fact that it is less common today.

Advantages of THT

• Stronger Connections: THT components are physically anchored to the board, making them more resistant to mechanical stress.

• Reliable for Power Components: THT is often preferred for high-power components that require more robust connections.

8. Mixed Technology PCB Assembly

Mixed technology PCB assembly is a method sometimes combined by machine (THT) and surface mount technology (SMT).This method is often employed when a design requires the benefits of both SMT and THT.

When to Use Mixed Technology

• Complex Circuits: Mixed technology is ideal for complex circuits that require both small components (SMT) and robust connections (THT).

• Individual Designs: With this method, custom designs can be more flexible and accommodate a wide variety of component sizes and types.

9. The cost of good security

Maintaining the final product’s dependability necessitates checking that each board is error-free and works as intended.

Testing Methods

•Automated Optical Inspection (AOI): This technique looks for PCB flaws such soldering problems or missing components using cameras.

• X-Ray Inspection: X-rays are used to examine the internal structure of the PCB, checking for hidden defects that might not be visible through other methods.

• Functional Testing: The assembled PCB is powered on and tested under normal operating conditions to ensure it performs as expected.

10. Challenges in PCB Assembly

PCB Assembly is a complex process with several challenges that manufacturers must overcome to produce high-quality boards.

Miniaturization

As devices become smaller, the components used in PCBs must also shrink. This miniaturization presents challenges in both the design and assembly processes.

Heat Management

Overseeing heat is basic in PCB Assembly, particularly in high-power circuits. Overheating can cause damage to the board’s components and shorten its lifespan.

Material Selection

Material Selection The PCB’s durability, performance, and cost-effectiveness are all dependent on selecting the appropriate materials. Delamination and poor electrical performance are two potential outcomes of selecting the wrong material.

11. Advancements in PCB Assembly

New Technologies and Methods for PCB Assembly The field of PCB Assembly is constantly developing new technologies and methods to increase functionality, reduce costs, and increase efficiency.

Flexible PCBs

Flexible PCBs are produced using adaptable materials, permitting them to be twisted or collapsed. This adaptability opens up new design and application possibilities, particularly for wearable electronics.

3D Printing

As a way to make PCBs, 3D printing is being looked into because it allows for quick prototypes and individualized designs.

Automated Inspection

Automated Inspection Technologies like machine learning algorithms are making improvements to the speed and accuracy of quality control procedures.

12. Applications of PCB Assembly

Applications of PCB Assembly PCB Assembly is utilized in numerous applications, including industrial machinery and consumer electronics. The uses that are used the most are listed below. Here are the absolute most normal purposes.

Consumer Electronics

The majority of consumer gadgets, including tablets, televisions, and smartphones, require PCB construction. PCBs are at the heart of these devices, providing the foundation for their operation.

Automotive Industry

PCBs are utilized in engine control systems and entertainment systems for automobiles in the automotive industry. The PCB’s dependability and durability are crucial in this industry.

Medical Devices

Medical Devices often rely on PCB Assembly for their operation, from simple diagnostic tools to complex imaging equipment. In this industry, the PCB’s precision and dependability are absolutely necessary.

Telecommunications

PCB assembly is crucial to the telecommunications industry’s use of network equipment such servers, switches, and routers. The efficiency and speed of these devices are crucial for maintaining communication networks.

13. Choosing the Right PCB Manufacturer

The following should be kept in mind:

Knowledge and expertise

Knowledge and skill Choose a manufacturer with prior experience and a track record of success in your particular application. High-quality boards are more likely to be produced by manufacturers with experience.

Customization Options

Options for Customization If you need unique designs or materials, look for a manufacturer that offers customization options. You need flexibility to meet your specific needs.

14. Environmental Impact of PCB Assembly

Like many other manufacturing processes, PCB assembly has an effect on the environment. For sustainable products to be produced, it is essential to comprehend and mitigate this impact.

Waste Management

Management of Waste PCB Assembly generates waste, which includes unused components, faulty boards, and hazardous chemicals. For minimizing harm to the environment, proper waste management practices like recycling and secure disposal are essential.

Energy Consumption

The PCB Assembly process consumes energy, particularly in steps like reflow soldering. Reducing energy consumption through efficient processes and equipment can lessen the environmental footprint.

Eco-Friendly Materials

Using eco-friendly materials in PCB Assembly, such as lead-free solder and recyclable substrates, can help reduce the environmental impact of the final product.

15. Future Trends in PCB Assembly

The future of PCB Assembly is exciting, with several trends shaping the industry.

Miniaturization and Integration

The demand for small and multifunctional PCBs will continue to rise as devices get smaller and more integrated. This trend is driving advancements in materials, design, and assembly techniques.

Sustainability

The push for sustainability is leading to the development of greener PCB Assembly methods, such as using biodegradable materials and reducing energy consumption.

AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are being increasingly integrated into PCB Assembly processes, particularly in areas like design optimization and quality control.

16. Last Words

PCB assembly, also known as printed circuit board assembly, is a basic procedure utilized in the creation of contemporary electronics. Every step, from the design phase to the final inspection, is important for making a circuit that works and is reliable. PCB Assembly will continue to develop in tandem with technological advancement, opening up new avenues for innovation and efficiency.

Anybody interested in electronics, whether a professional, student, or hobbyist, has to understand PCB assembly., or a professional. By breaking down complex concepts into simple terms, this guide aims to make the world of PCB Assembly accessible to everyone.

17. FAQs

1. What is the distinction among PCB and PCB Assembly?

A PCB is an uncovered board that gives the establishment to an electronic circuit, while PCB Assembly alludes to the method involved with connecting parts to the PCB to make a practical circuit.

2. What are the principal kinds of PCB Assembly?

The fundamental sorts of PCB Assembly are Single-Sided, Twofold Sided, and Multi-facet Assembly, each appropriate for various applications in light of intricacy and size.

3. For what reason is quality control significant in PCB Assembly?

Quality control guarantees that the collected PCB is liberated from imperfections and works accurately, which is critical for the dependability and execution of the eventual outcome.

4. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a technique for mounting parts straightforwardly onto the surface of the PCB, taking into consideration more reduced and proficient plans.

5. How is the ecological effect of PCB Assembly being tended to?

The natural effect of PCB Assembly is being tended to through squander the executives, energy-proficient cycles, and the utilization of eco-accommodating materials.