In the PCBA manufacturing facility of digital tools, dirt, and other impurities are not totally secured. Dirt can easily penetrate the vents and port slots on the housing and collect on the motherboard. Additionally, the rotational motion of followers, particularly in huge makers, can blow infected air onto the circuit card.

Deionized or Pure Water

Because tough water includes ions that bring electric present, lots of people select deionized or distilled water because it will certainly not damage circuit card. When not being used, make certain your water container is closed to stop contamination from dust and dust bits.

Pressed Air

Usage short bursts of compressed air to blow air into the open spaces of the tool to get rid of dirt that has built up on surface areas, including inside the circuits, without any disruptions. When these openings are small, you can open up the device and use pressed air to effectively clean up the motherboard.

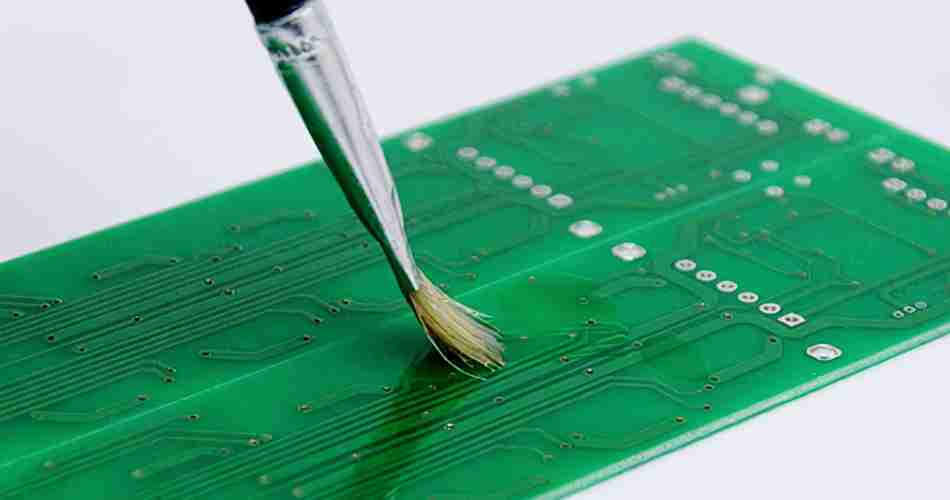

In addition to the circuit board cleaner, you will require an extra device to aid clean or sweep aside impurities.

Baking soda

Sodium bicarbonate can be made use of to get rid of corrosion on PCBs. This corrosion is caused by acid leaks and exposure to salted water. The mild abrasiveness of the soft drink removes rust without unfavorable results.

PCBA circuit card producers utilize turned on rosin-based change. However, because these products contain aspects such as chlorine, the deposit left after soldering can create rust. As a result, PCBA suppliers have developed a variety of PCB board cleaner fluid technologies to replace halides. Many circuit card producers use no-clean flux, which has natural acids such as citric acid and adipic acid.

This organic acid is promptly decayed by the heat of soldering and sticks strongly to the solder, leaving a little harsh. This used solder often covers some of the change, avoiding the warm required for malfunction. After manufacturing, residues of some deterioration modifications are left on these soldered components. It might be better if you get rid of the debris to ensure the best performance of the PCB during its service life.

Workdesk lamp, stove, or hair dryer

While the above cleansers can assist remove dirt, some might likewise leave fluid behind. Use a warmth source to wipe it off promptly to stay clear of harming the board. This method is necessary when following the directions on just how to wipe the board.

Vapor Stage Cleaners

Vapor phase cleaning needs boiling any kind of chemical solvent that generates vapor to dissolve contaminations that have actually built up on the PCBA.

Microfiber apparel or lint-free towels

Towels can be made use of to promptly rub out cleaning liquids. To lower the possibility of leaving bits in your gadgets, they need to be lint-free or constructed from microfiber.

Isopropyl Alcohol

Due to the fact that it is affordable and evaporates rapidly, isopropyl alcohol stays a perfect device for cleaning up circuits. In addition, the beverage contains less chemicals than traditional PCB cleaners. Always wear gloves when making use of isopropyl alcohol, as it includes a high concentration (over 90%) that can harm your skin.