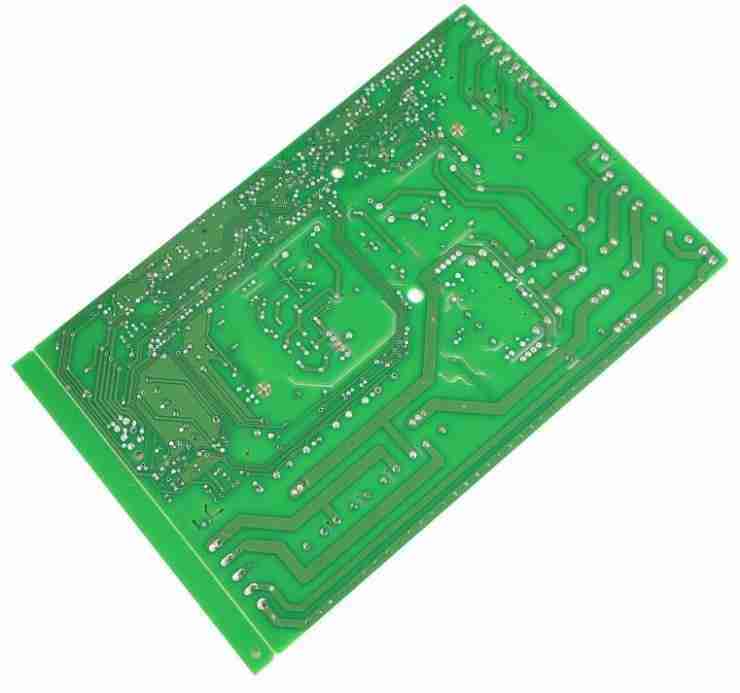

High Quality PCB establishes minimum criteria for motherboard manufacturing and setting up. It consists of three performance classifications based on specifications and specifications for procedure and integrity assumptions. Nonetheless, for all groups, PCB manufacturing consists of the adhering to actions.

Step 1, Imaging The first step in PCB manufacturing is to create an image of the circuit. It is for not only the leading and lower layers of the board however additionally the internal layers of the pile for a multi-layer design. The copper layer is covered with photoresist and exposed to light.

Step 2, Etching (Internal Layers) Etching is the process of eliminating copper from all locations except traces or various other conductor points. Ammonia-based services are normally made use of.

Step 3, Piling For this step, the circuit card layers (substrate and laminate) are stacked, straightened, and heat-pressed together.

Tip 4, Boring With holes and mounting openings are drilled via these layers. It is essential to follow the appropriate exploration procedure right here and stick to aspect ratio constraints.

Step 5, Etching (External Layers) For the outer layers, the photoresist and excess copper should be eliminated.

Step 6, PCB Plating Drilling holes with copper plating enable present flow between layers.

Step 7, Solder Mask A Solder mask is a polymer film, usually environment-friendly, black, red, yellow, or white, that shields non-conductive surface areas.

Step 8, Silk Screen Application This is where tags, polarity signs, pin one indications, and various other details are published on the surface of boards. These are generally applied by an inkjet printer.

Step 9, Include Surface End up The main feature of surface area coating is to protect copper locations from environmental dangers, particularly wetness and oxidation.

PCB handling creates the bare board or PCB without any component, which need to not be puzzled with PCB setting up (PCBA), where components soldering onto the board. The onset of PCBA production rely greatly on centimeters procedures and equipment. Nonetheless, the design options you make assistance identify whether your board is produced efficiently.