Circuit card assembly (CCA) and printed circuit board (PCB) quote package are vital angles of electronic fabricating. These forms drop beneath the umbrella of electrical building and fabricating building, with critical cover into mechanical building hones. Let’s investigate these subjects in profundity to get it their significance in the cutting edge gadgets’ industry.

Circuit Card Assembly (CCA)

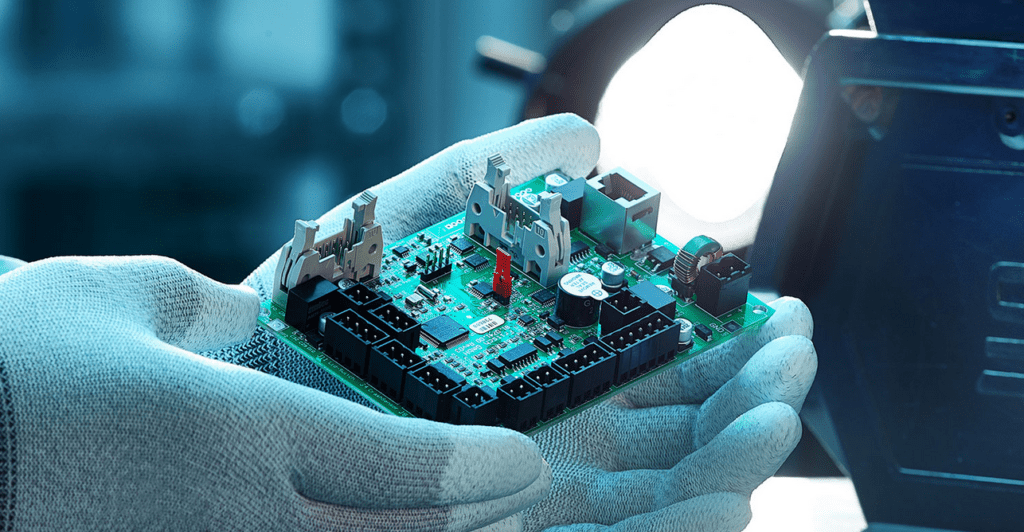

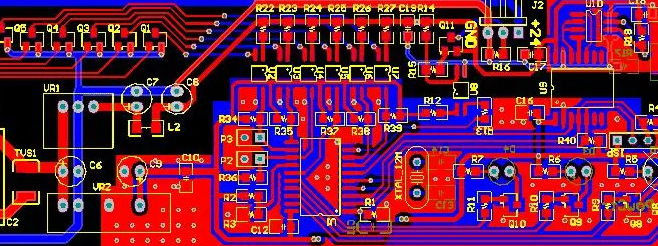

Circuit card assembly, moreover known as printed circuit board assembly (PCBA), is the handle of populating printed circuit sheets with electronic components to make useful electronic circuits. This prepares is a basic step in the fabricating of electronic gadgets, from basic shopper contraptions to complex mechanical and military equipment.

The circuit card assembly prepare ordinarily includes a few stages:

1. PCB Manufacture: Some time recently assembly can start, the uncovered PCB must be fabricated. This includes making the board from layers of protection fabric (ordinarily fiberglass) and conductive copper follows. The board is outlined to mechanically bolster and electrically interface electronic components utilizing conductive pathways carved from copper sheets covered onto a non-conductive substrate.

2. Component Acquirement: All vital electronic components must be sourced and secured. These may incorporate resistors, capacitors, inductors, diodes, transistors, coordinates circuits, connectors, and different other electronic parts indicated in the charge of materials (BOM).

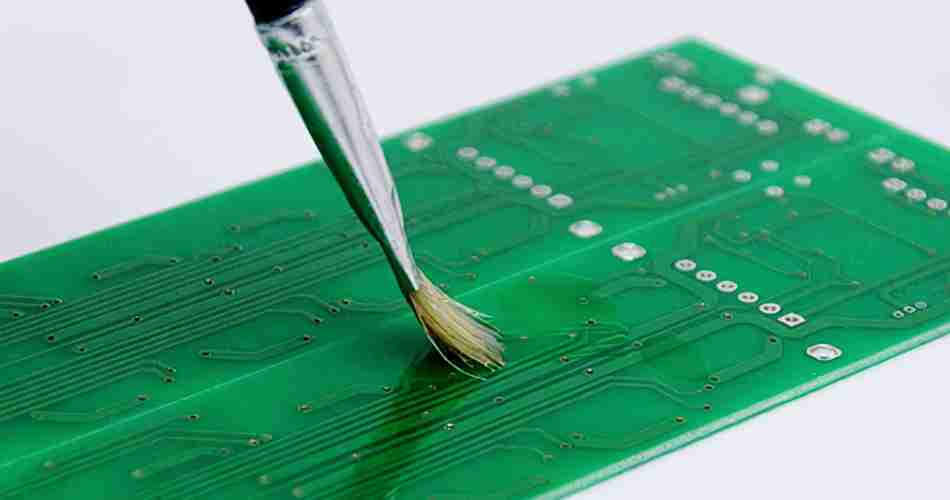

3. Solder Glue Application: For surface-mount technology (SMT) components, patch glue is connected to the PCB utilizing a stencil. The stencil has openings that compare to the component cushions on the board. Patch glue, a blend of minor patch particles and flux, is spread over the stencil, storing it absolutely where components will be placed.

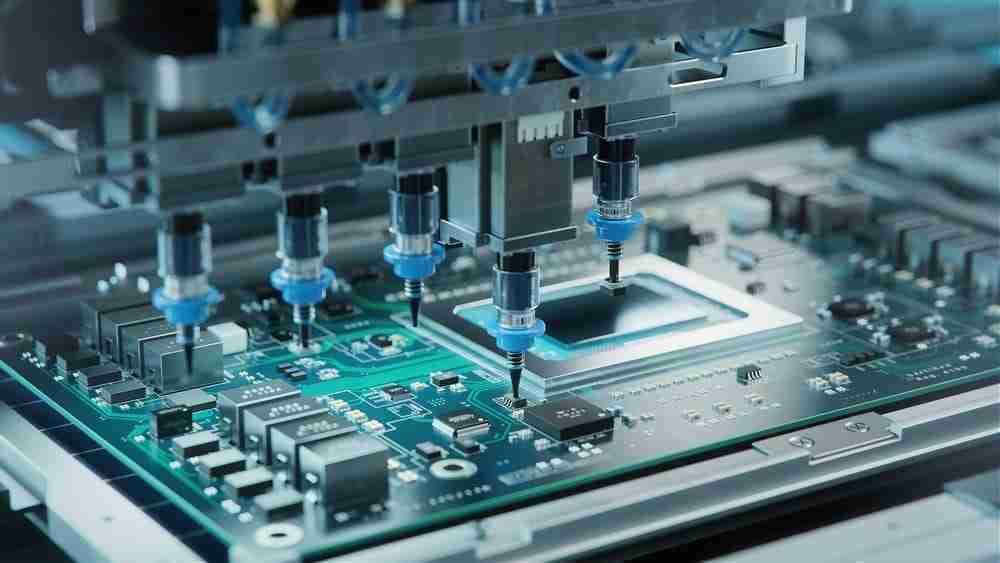

4. Component Situation: SMT components are put onto the board utilizing mechanized pick-and-place machines. These high-speed robots can put thousands of components per hour with tall exactness. For through-hole components, this step may be done physically or with specialized inclusion machines.

5. Reflow Fastening: The populated board is passed through a reflow broiler, where carefully controlled warm dissolves the patch glue, making lasting electrical associations between the components and the board.

6. Inspection and Testing: After reflow, the manufacturers are assessed outwardly and frequently utilizing Automated Optial Inspection (AOI) frameworks. X-ray review may be utilized for components with covered up associations. Electrical tests are performed to guarantee functionality.

7. Through-Hole Component Insertion: If the plan incorporates through-hole components, they are embedded after the SMT. This can be done physically or with computerized addition equipment.

8. Wave Patching: For sheets with through-hole components, wave patching is frequently utilized. The foot of the board is passed over a wave of liquid patch, which follows to the uncovered metal leads and pads.

9. Final Review and Utilitarian Testing: The completed assembly experiences last visual review and useful testing to guarantee it meets all indicated requirements.

10. Conformal Coating (Discretionary): A few manufacturers, especially those predetermined for harsh environment situations, use a conformal coating to ensure against dampness, tidy, and chemical contaminants.

11. Packaging and Shipping: The wrapped up circuit card assembly are bundled to ensure them from electrostatic discharge (ESD) and physical harm amid transport.

Advanced Contemplations in Circuit Card Assembly

1. High-Speed PCB Plan and Assembly: As electronic gadgets work at progressively higher frequencies, extraordinary contemplations must be taken in both PCB plan and assembly:

• Controlled Impedance: Keeping up steady impedance transmission line follows gets to be vital. This requires exact control of line width, line thickness, and dielectric properties.

• Signal Integrity: Minimizing crosstalk, reflections, and electromagnetic impedance (EMI) gets to be more challenging. Methods such as differential pair, watch follows, and legitimate stackup plan are essential.

• Material Determination: High-frequency covers like Rogers or PTFE-based materials may be fundamental for ideal performance.

2. Thermal Administration in circuit card assembly: With expanding control densities, warm administration gets to be a basic viewpoint of circuit card assembly:

• Thermal Vias: Consolidating warm vias to conduct warm absent from hot components to cooling planes or warm sinks.

• Copper Pad Innovation: Utilizing copper pads of sufficient thickness to upgrade heat dissipation capacity for high-power components.

• Thermally Conductive Materials: Utilizing thermally conductive however electrically protection materials for superior warm distribution.

3. Embedded Components: The slant towards miniaturization is driving the appropriation of inserted component technology:

• Electronic components like resistors and capacitors can be implanted inside the PCB layers.

• Benefits include saving space, improving performance, reduce costs, and better functional integration.

• Challenges incorporate more complex fabricating forms and potential challenges in rework.

4. Heterogeneous Integration: Combining diverse sorts of components and innovations on a single substrate:

• System-in-Package (SIP) arrangements joining different pass on, inactive components, and in some cases radio wires in a single package.

• 2.5D and 3D IC bundling advances utilizing interposers or stacked pass on configurations.

5. Flex and Rigid-Flex Gatherings: Expanding request for adaptable and rigid-flex PCBs presents one of a kind assembly challenges:

• Careful dealing with to avoid harm to adaptable sections.

• Specialized tooling and installations for assembly and testing.

• Considerations for energetic twist locales and stretch relief.

6. Reliability Upgrade: For high-reliability applications like aviation, car, or restorative devices:

• Conformal Coating: Application of defensive coatings to shield gatherings from natural factors.

• Bottom filling: Utilizing epoxy resin bottom filling to make strides the unwavering quality of BGA and flip-chip components.

• package: Connect the chips to external pins for protection.

PCB Quote Packaging

PCB quote package alludes to the handle of planning and showing a comprehensive cite for the fabricate of printed circuit sheets or completely amassed circuit card gatherings. This handle is a basic portion of the commerce side of electronic fabricating and includes a few designing disciplines, counting electrical, fabricating, and mechanical engineering.

Key components of PCB quote package include:

1. Design Audit: Engineers analyze the customer’s PCB plan records, counting Gerber records, penetrate records, and details. They check for any potential fabricating issues or plan optimizations that might move forward abdicate or decrease cost.

2. Material Determination: Based on the plan necessities, fitting PCB materials are chosen. This incorporates the base fabric (e.g., FR-4, high-frequency covers), copper weight, and any uncommon materials required for specific applications.

3. Layer Stack-up Definition: For multi-layer sheets, the layer stack-up is characterized, indicating the number of layers, their course of action, and the dielectric materials between them.

4. Manufacturing Prepare Arranging: The fabricating steps are arranged out, counting any uncommon forms required (e.g., dazzle or buried vias, controlled impedance, etc.).

5. Component Sourcing: For turnkey assembly administrations, the accessibility and fetched of all required components are decided. This may include working with different providers to guarantee the best estimating and availability.

6. Production Volume Thought: The costs may change depending on the production volume. Bigger volumes regularly result in lower per-unit costs due to economies of scale.

7. Lead Time Estimation: The time required to total the arrangment is assessed, taking into account current production plans and the complexity of the project.

8. Quality Confirmation Arranging: The level of testing and review required is decided, which may incorporate Flying Probe Test, online AOI detection, utilitarian testing, or unwavering quality testing for basic applications.

9. Regulatory Compliance: Any fundamental certifications or compliance necessities (e.g., RoHS, REACH, UL) are figured into the quote.

10. Packaging and Shipping: The costs for package to ensure the PCBs or congregations amid shipping are included.

11. Profit Edge Calculation: A reasonable benefit edge is included to cover overhead costs and guarantee the supportability of the business.

12. Quote Introduction: The last cite is compiled into a clear, proficient archive that traces all costs, details, terms, and conditions.

Engineering Disciplines Involved

PCB quote package includes a few building disciplines:

1. Electrical Designing: Electrical engineers are vital in the plan survey handle. They get it the electrical prerequisites of the PCB and can recognize potential issues or recommend enhancements. They moreover play a key part in indicating testing strategies to guarantee the usefulness of the wrapped up product.

2. Manufacturing Designing: Fabricating engineers are capable for arranging the generation prepare. They decide the most proficient way to create the PCBs or congregations, select suitable hardware and forms, and optimize the fabricating stream to diminish costs and make strides quality.

3. Industrial Designing: Mechanical engineers center on optimizing complex forms and frameworks. In PCB fabricating, they may be included in progressing generation effectiveness, decreasing squander, and actualizing incline fabricating standards. They too play a part in fetched estimation and generation scheduling.

4. Materials Designing: Materials engineers may be counseled for selecting suitable PCB materials, particularly for high-performance or specialized applications. They get it how diverse materials carry on beneath different conditions and can prescribe the best choices for particular requirements.

5. Quality Designing: Quality engineers create and actualize quality control and affirmation forms. They guarantee that the made PCBs and gatherings meet all indicated prerequisites and industry standards.

6. Software Building: Computer program engineers may be included in creating and keeping up the computer program frameworks utilized for plan examination, cite era, and generation management.

Challenges in PCB Quote Packaging

Several challenges can emerge in the PCB quote package process:

1. Design Complexity: As electronic plans ended up more complex, with higher component densities and more layers, precisely evaluating fabricating costs gets to be more challenging.

2. Material Variances: The costs of crude materials, particularly copper, can vary essentially, influencing the exactness of long-term quotes.

3. Component Accessibility: In turnkey assembly ventures, the worldwide semiconductor deficiency has made it troublesome to precisely foresee component accessibility and pricing.

4. Technological Headways: Quick progressions in PCB innovation require persistent overhauls to fabricating capabilities and costing models.

5. Competitive Weight: The exceedingly competitive nature of the hardware fabricating industry puts weight on producers to give competitive cites whereas keeping up profitability.

6. Regulatory Changes: Advancing directions and measures can affect fabricating forms and costs, requiring visit upgrades to citing procedures.

Future Patterns in circuit card assembly and PCB Manufacturing

Several patterns are forming the future of circuit card gathering and PCB manufacturing:

1. Increased Computerization: More noteworthy utilize of mechanical technology and counterfeit insights in the assembly handle is moving forward productivity and diminishing human error.

2. Industry 4.0 Integration: The integration of keen fabricating standards, counting real-time information collection and investigation, is optimizing generation processes.

3. Additive Fabricating: 3D printing innovations are being investigated for creating PCBs, possibly revolutionizing prototyping and small-batch production.

4. Flexible and Stretchable Gadgets: Progresses in materials and fabricating procedures are empowering the generation of adaptable and stretchable PCBs for wearable and IoT applications.

5. Miniaturization: Proceeded request for littler, more capable gadgets is driving the advancement of high-density interconnect (HDI) and microvia technologies.

6. Green Fabricating: Expanding center on maintainability is driving to the improvement of more naturally inviting PCB materials and fabricating processes.

Conclusion

Circuit card assembly and PCB quote package are complex forms that sit at the crossing point of different building disciplines. They require a profound understanding of electrical plan standards, fabricating forms, materials science, and commerce hones. As the hardware industry proceeds to advance, driven by requests for littler, speedier, and more complex gadgets, the significance of productive and exact circuit card assembly and PCB quote package will as it were develop. Producers who can explore these challenges whereas grasping modern advances and techniques will be well-positioned to succeed in this energetic and fundamental industry.

The areas of circuit card gathering and PCB quote package are ceaselessly advancing, driven by propels in innovation, changing advertise requests, and expanding complexity of electronic gadgets. Victory in this industry requires a multidisciplinary approach, combining skill in electrical designing, fabricating forms, materials science, and commerce strategy.

As we see to the future, a few key patterns are likely to shape the industry:

• Increased integration of progressed innovations like AI, IoT, and AR into fabricating processes.

• Greater accentuation on maintainability and natural duty in both plan and manufacturing.

• Continued thrust towards miniaturization and expanded usefulness, driving developments in materials and assembly techniques.

• More all encompassing approach to citing, considering add up to taken a toll of possession and long-term esteem or maybe than fair forthright costs.

• Greater center on adaptability and flexibility in fabricating to meet quickly changing advertise demands.

For experts in this field, remaining side by side of these improvements and persistently upgrading aptitudes and information will be vital. The capacity to adjust specialized skill with trade intuition, to explore complex supply chains, and to adjust to unused advances will be key differentiators in this competitive industry.

As electronic gadgets ended up ever more fundamentally to our day by day lives and basic frameworks, the significance of effective, solid, and inventive circuit card assembly and PCB fabricating will as it were develop. Those who can ace these complex forms whereas adjusting to the changing mechanical scene will be well-positioned to lead the industry into the future.