Printed Circuit Boards (PCBs) serve as the spine of nearly all advanced electronic gadgets, empowering the usefulness, unwavering quality, and miniaturization we have come to anticipate. Among the different sorts of PCBs, Surface Mount PCBs (SMT PCBs) have risen as a foundation Technology. Surface Mount Technology (SMT) speaks to a noteworthy progression over the more seasoned through-hole Technology, advertising way better execution, diminished costs, and more prominent versatility to the requests of present day electronics.

This comprehensive Content will investigate what Surface Mount PCBs are, how they work, and why they are fundamental to the advanced world.

What is a Surface Mount PCB?

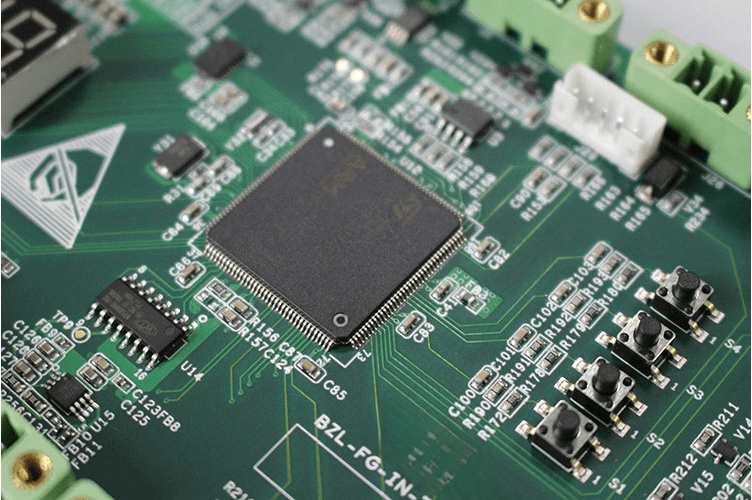

A Surface Mount PCB utilizes Surface Mount Technology, where components are straightforwardly mounted onto the surface of the board or maybe than embedded into gaps that navigate the PCB. These Boards include compact, lightweight plans and encourage the mounting of a wide cluster of surface mount components (SMDs).

Components like resistors, capacitors, and microcontrollers are patched onto the PCB’s surface, permitting for altogether higher circuit densities. Not at all like their through-hole partners, SMDs do not have long leads. This structure is imperative in making advanced and miniaturized plans like keen phones, wearables, and mechanical computerization systems.

How Does Surface Mount Technology Work?

The get together handle of a Surface Mount PCB includes a few efficient steps, all of which contribute to the creation of vigorous, productive, and high-performing circuits. Underneath is a nitty gritty clarification of the SMT process:

1. PCB Design

The travel starts with planning the PCB format utilizing progressed Computer-Aided Design (CAD) program. Engineers carefully arrange component situation and directing to accomplish ideal execution and manufacturability.

2. Applying Solder Paste

Once the PCB format is prepared, a lean layer of patch glue is connected to ranges where the components will be connected. This glue comprises of tiny patch balls suspended in a flux medium, making a difference secure components amid soldering.

3. Component Placement

Modern Pick-and-Place machines accurately position SMDs onto the patch paste-covered cushions. These machines guarantee mind blowing precision, indeed at amazingly tall speeds, to handle thick, complex designs.

4. Reflow Soldering

After putting components, the PCB passes through a reflow broiler. The patch glue dissolves, making vigorous electrical and mechanical bonds between the components and the PCB. After cooling, the patch cements, settling the components in place.

5. Assessment and Testing

Automated Optical Inspection (AOI) frameworks check for arrangement and patching issues, guaranteeing the quality of the collected PCB. For progressed or basic circuits, X-ray reviews and utilitarian tests are conducted to confirm the astuteness of patch joints and component placement.

6. Last Assembly and Quality Assurance

Completed PCBs are coordinates into walled in areas or congregations. A last circular of testing guarantees unwavering quality and compliance with plan specifications.

Advantages of Surface Mount PCBs

Surface Mount Technology offers various preferences over conventional through-hole plans, making it the favoured choice in present day electronics:

1. Miniaturization

SMDs are littler and lighter than through-hole components, permitting for compact and convenient gadget plans. This capability is fundamental for applications like smartphones and IoT devices.

2. Higher Circuit Density

Surface mounting empowers the utilize of both sides of the PCB, permitting more components in a given region. This advantage comes about in complex, multifunctional circuits inside restricted space constraints.

3. Upgraded Performance

The shorter leads of SMDs minimize parasitic inductance and capacitance, making strides flag keenness and empowering high-speed operation.

4. Taken a toll Efficiency

Automated get together forms and decreased fabric costs make SMT exceedingly temperate, especially for large-scale production.

5. Ease of Automation

SMT is well-suited for robotized manufacturing forms, guaranteeing tall unwavering quality, consistency, and generation scalability.

Why Surface Mount PCBs are Fundamental in Present day Electronics

In today’s world, where Technology is progressing at breakneck speed, Surface Mount PCBs have ended up irreplaceable. Their one of a kind capabilities adjust impeccably with the requests of present day applications, cultivating advancement over different divisions. Let’s plunge more profound into why SMT PCBs are vital:

1. Consumer Electronics

Devices such as smart phones, tablets, portable workstations, and wearable Technology depend intensely on SMT PCBs. Their little measure, moo weight, and capacity to coordinated exceedingly advanced circuits are significant for the compact however effective nature of advanced gadgets.

2. Consumer Industry

The automotive segment requests strong PCBs able of withstanding cruel situations and giving dependable execution. SMT PCBs cater to these prerequisites by empowering Advanced Driver-Assistance Systems(ADAS), infotainment frameworks, and motor administration systems.

3. Healthcare Technology

Medical gadgets require miniaturized gadgets with tall unwavering quality. SMT PCBs play a essential part in creating symptomatic devices, wearable wellbeing screens, and imaging systems.

4. Mechanical Automation

SMT PCBs enable progressed apparatus and mechanical autonomy with compact plans, moo control utilization, and high-performance capabilities, upgrading productivity and productivity.

5. Aviation and Defense

Space-constrained and rough gadgets, basic in aviation and defense, depend on SMT PCBs for progressed usefulness and tall reliability.

Challenges Related with Surface Mount PCBs

While SMT PCBs offer exceptional points of interest, they moreover display certain challenges, including:

1. Complex Repairs

Due to the little measure of SMDs, repairs can be challenging, requiring specialized devices and expertise.

2. Beginning Setup Costs

The introductory speculation in SMT hardware and apparatuses can be considerable, in spite of the fact that it is counterbalanced by taken a toll investment funds in large-scale production.

3. Thermal Management

High circuit densities increment warm requests, requiring progressed warm dissemination procedures to maintain a strategic distance from execution degradation.

Trends and Innovations in SMT PCBs

The world of Surface Mount Technology proceeds to advance. Here are a few developing patterns and developments forming the future:

1. Progressed Materials

Technologies in materials, such as high-temperature covers and conductive cements, are improving the execution and toughness of SMT PCBs.

2. Miniaturization Continues

The slant toward miniaturization remains solid, driving the improvement of indeed littler SMDs, progressed situation machines, and more complex plan techniques.

3. Natural Considerations

Sustainable manufacturing hones and lead-free patching are getting to be standard in SMT PCB generation to meet worldwide natural regulations.

Conclusion

Surface Mount PCBs are a wonder of designing, revolutionizing the world of gadgets with their compact plans, prevalent execution, and cost-effectiveness. Their part in present day Technology ranges buyer contraptions, healthcare gadgets, mechanical frameworks, and past, exhibiting unparalleled versatility.

As development pushes the boundaries of what’s conceivable, SMT PCBs will stay at the bleeding edge of the hardware insurgency. By empowering more modern, productive, and miniaturized plans, they proceed to shape the mechanical scene, making our present day ways of life conceivable.