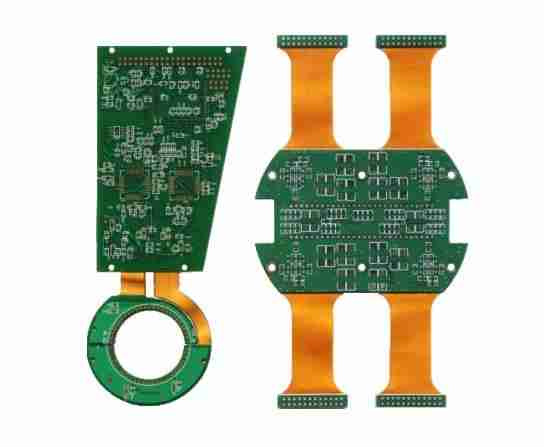

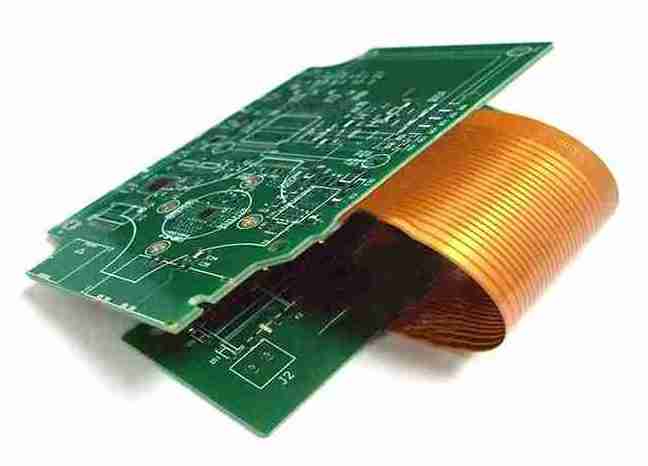

In the ever-evolving world of electronics, advancement drives the require for more progressed, compact, and effective plans. Rigid-flex boards are composed of different layers, a few unbending (as a rule made of materials like FR4) and a few flexible (regularly made from polyimide or other flexible substrates). These boards include rigid segments that hold electronic components and flexible areas that permit the PCB to twist, overlay, or bend, making them perfect for complex, space-constrained applications.

Rigid-flex boards are regularly outlined in such a way that the flexible regions can be bowed to accommodate to a specific shape or be collapsed to fit inside kept spaces. This makes them profoundly appropriate for applications where adaptability and strength are basic, and where conventional unbending boards would be as well bulky or impractical.

Components of a Rigid-Flex PCB

A rigid-flex circuit board is built utilizing different layers, fair like customary printed circuit boards, but with an included layer of adaptability. The essential components include:

1. Rigid Layers: These are the difficult, non-flexible layers of the PCB that give the mechanical back required for the PCB to work successfully. These layers are ordinarily made from materials such as fibreglass-reinforced epoxy (FR4), which is tough and robust.

2. Flexible Layers: The flexible parts of the PCB are ordinarily made from polyimide or other flexible materials that permit the board to be bowed or bent without losing electrical keenness. These layers give the essential adaptability to adjust to three-dimensional shapes.

3. Interconnection Layers: These are the layers that interface both the rigid and flexible areas of the board. They are planned to guarantee that the electrical associations stay intaglio indeed when the flexible portion of the PCB is bowed or folded.

4. Solder Veil and Copper Follows: The copper follows on the board give electrical associations between components. The patch veil ensures these follows from harm and oxidation. These components are coordinates into both the rigid and flexible parts of the PCB.

Advantages of Rigid-Flex Circuit Boards

Rigid-flex circuit boards offer various points of interest over conventional rigid PCBs and flexible PCBs, making them profoundly looked for after in present day gadgets. A few of the key benefits include:

1. Space Effectiveness and Compact Design

One of the essential points of interest of rigid-flex circuit boards is their capacity to empower exceedingly compact and space-efficient plans. The flexible segments permit for imaginative format conceivable outcomes that wouldn’t be achievable with conventional unbending boards. Engineers can plan a item that fits in a little or ungracefully molded space by utilizing flexible zones that twist and accommodate to the required shape. This compactness is basic in businesses such as buyer gadgets, restorative gadgets, and aviation, where lessening the measure and weight of gadgets is a beat priority.

2. Diminished Assembly Complexity

Rigid-flex PCBs combine the benefits of both rigid and flexible plans, meaning less intercontinental and parts are required in the Assembly handle. By coordination rigid and flexible components into a single board, producers can kill the require for extra connectors or wires between partitioned unbending and flexible parts, coming about in a less complex and more streamlined gathering. This not as it were diminishes the complexity of fabricating but too cuts down on the potential for disappointments due to destitute associations or Assembly issues.

3. Expanded Durability

The flexible nature of rigid-flex circuit boards permits them to withstand physical push, twisting, and development. Not at all like conventional rigid PCBs, which can split or break beneath stretch, rigid-flex boards are exceedingly safe to weakness and mechanical harm. This makes them perfect for gadgets that encounter visit development, vibration, or introduction to cruel conditions, such as automotive gadgets, military electronics, and convenient shopper electronics.

4. Improved Reliability

Rigid-flex boards are known for their unwavering quality, especially in requesting applications. Since the flexible segments are consolidated into the same board, there is less probability of mechanical disappointment due to patch joints breaking or connectors getting to be free. Moreover, rigid-flex boards can be outlined to be more safe to warm, dampness, and natural wear, driving to an generally increment in item longevity.

5. Cost-Effective in the Long Term

Though the beginning taken a toll of fabricating rigid-flex boards may be higher than conventional PCBs due to their complexity, they can demonstrate to be more cost-effective in the long run. The diminishment in Assembly steps, less components, and the capacity to fit a gadget in littler spaces can offer assistance spare costs in terms of both materials and labor. Moreover, the expanded strength and life span of these boards result in less substitutions or repairs, assist diminishing generally costs.

6. Superior Flag Integrity

Signal judgment is basic in advanced electronics, especially in high-speed or high-frequency applications. Rigid-flex boards permit for shorter interconnects and less flag misfortune, which comes about in superior execution, especially in delicate or high-performance frameworks. The plan adaptability permits engineers to optimize the steering of electrical follows for ideal flag integrity.

Applications of Rigid-Flex Circuit Boards

Rigid-flex circuit boards are finding applications over a wide run of businesses, much appreciated to their special mix of toughness, adaptability, and compactness. A few of the key businesses and applications that depend on rigid-flex PCBs include:

1. Consumer Electronics

In consumer electronics such as smart phones, wearables, and portable workstations, space and weight are basic plan variables. Rigid-flex circuit boards are commonly utilized in these gadgets to diminish measure whereas keeping up tall execution and strength. The flexible segments permit gadgets to have more compact plans and way better ergonomic highlights, whereas the unbending areas back the vital components and connectivity.

2. Restorative Devices

In the restorative field, especially in symptomatic and observing gear, unwavering quality and compactness are fundamental. Rigid-flex PCBs are commonly utilized in wearable wellbeing gadgets, such as shrewd observes, heart screens, and hearing helps. The boards’ toughness and capacity to withstand natural variables such as dampness and temperature make them perfect for therapeutic applications.

3. Aviation and Military

Aerospace and military applications request high-performance, solid gadgets that can withstand extraordinary conditions. Rigid-flex circuit boards are utilized in communication frameworks, flying, and military-grade sensors. These applications frequently require PCBs that can work in situations with tall vibration, extraordinary temperatures, and mechanical push, and rigid-flex PCBs offer these capabilities.

4. Automotive Electronics

The automotive industry has seen critical headways in electronic frameworks, particularly with the rise of electric vehicles (EVs) and independent driving advances. Rigid-flex PCBs are utilized in automotive sensors, route frameworks, and infotainment gadgets due to their resistance to vibration, temperature extremes, and moisture.

5. Mechanical Equipment

In mechanical apparatus and mechanical autonomy, the require for strength, adaptability, and accuracy is basic. Rigid-flex PCBs are frequently utilized in mechanical control frameworks, mechanical autonomy, and robotized apparatus, where tall unwavering quality is a key figure for smooth operations.

Conclusion

Rigid-flex circuit boards are an fundamental component of present day electronics, giving the culminate mix of adaptability, compactness, and toughness. As gadgets proceed to shrivel in estimate and increment in complexity, the part of rigid-flex PCBs gets to be indeed more vital. They empower engineers to plan littler, more effective items whereas keeping up execution and unwavering quality, making them a pivotal portion of businesses extending from shopper electronics to aviation. As innovation proceeds to progress, rigid-flex PCBs will without a doubt play an indeed more prominent part in forming the future of electronic gadgets.