In the ever-evolving world of electronics, manufacturers are continually endeavouring to make littler, lighter, and more capable electronics. One of the most critical headways empowering this transformation is the advancement of Surface Mount Technology (SMT) for circuit board manufacturing. SMT circuit boards are presently the foundation of present day electronics, driving advancements in everything from smart phones to Medical electronics and mechanical hardware. By empowering littler, more compact, and more dependable components, SMT is changing how we plan and utilize electronics.

In this Content, we’ll investigate how SMT circuit boards are forming the future of compact and proficient electronics. From their principal plan to their basic part in the hardware industry, we’ll dive into how SMT is driving advancement and making a difference companies thrust the limits of what’s possible.

Understanding SMT Circuit Boards

Before jumping into how SMT is changing the hardware industry, it’s fundamental to get it what SMT circuit boards are and how they vary from conventional through-hole Technology (THT) boards.

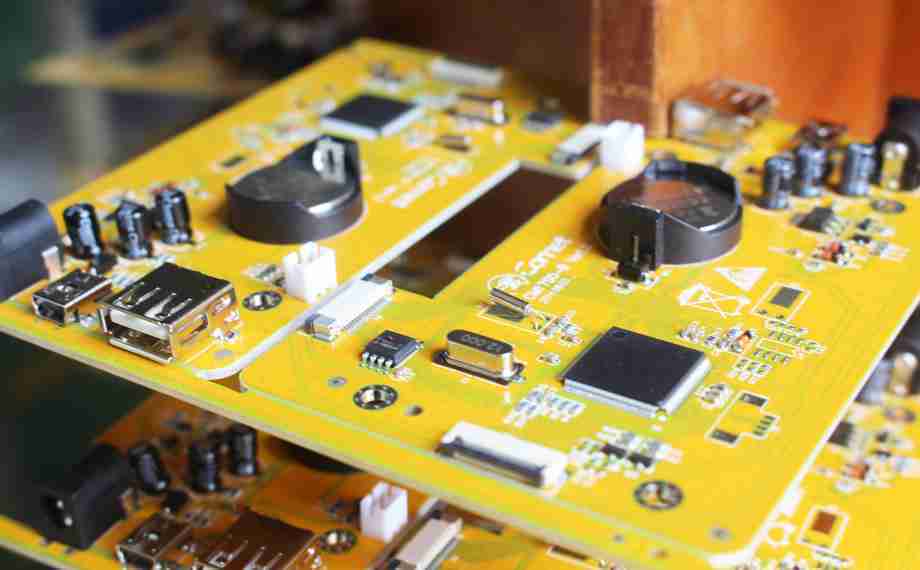

Surface Mount Technology (SMT) alludes to the strategy of mounting electronic components specifically onto the surface of a circuit board, or maybe than embeddings them into gaps as with conventional through-hole Technology. The components in SMT are little, and their leads (or pins) are patched to cushions on the board surface. This permits for a more compact plan, as the components can be set on both sides of the board, not at all like through-hole plans, which require space for the leads to pass through.

SMT components are as a rule littler and lighter than through-hole partners, which straightforwardly contributes to the slant toward miniaturization in hardware. The littler impression of SMT components too implies that circuit boards can contain more components in a given range, driving to higher usefulness in littler packages.

The Preferences of SMT in Compact Electronics

SMT has a run of benefits that make it the go-to choice for present day electronic electronics. These preferences are particularly basic in the setting of making compact and productive electronics:

1. Littler Estimate and Lightweight Design

One of the key focal points of SMT circuit boards is their capacity to encourage littler, more compact electronics. Since SMT components are set straightforwardly on the surface of the circuit board, manufacturers can plan boards with components on both sides, optimizing space utilization. This is in stark differentiate to through-hole Technology, which frequently requires a bigger board impression since the components require to fit into gaps penetrated through the board.

The diminishment in measure not as it were leads to littler items but moreover contributes to lighter electronics, which is basic in businesses such as portable Technology, wearables, and restorative electronics. For occasion, smart phones, portable workstations, and tablets have gotten to be continuously more slender and lighter over the a long time, much appreciated in portion to the effective utilize of SMT circuit boards.

2. Expanded Component Density

The compactness of SMT components permits for a higher component thickness on a circuit board, empowering architects to pack more usefulness into a littler space. This implies that electronics can have more complex and capable circuits whereas keeping up a moderately little shape factor.

For case, in Consumer hardware like smart phones, the request for more features—such as quicker processors, made strides cameras, and progressed sensors—has been developing exponentially. With SMT circuit boards, manufacturers can fit more components into the constrained space of a phone’s inside structure without compromising on measure or performance.

In businesses such as car or aviation, where space and weight are too basic, SMT circuit boards are empowering the integration of more progressed frameworks without expanding the measure or weight of the vehicle.

3. Improved Reliability

SMT components tend to have superior mechanical properties than their through-hole partners, which contributes to upgraded unwavering quality. This is since SMT components have shorter leads, which implies there is less chance of harm amid transport or establishment. Furthermore, since SMT components are patched specifically to the surface of the board, there is less stretch set on the board itself compared to conventional through-hole mounting.

In terms of execution, SMT circuit boards are less likely to endure from issues like destitute patch joints or broken leads, which can be more common in through-hole plans. This comes about in items with way better strength, making SMT a favoured choice in businesses where unwavering quality is vital, such as restorative hardware and car systems.

4. Quicker Manufacturing and Fetched Efficiency

The computerized nature of SMT generation lines is another figure that contributes to the developing selection of SMT circuit boards. Since SMT components are littler and lighter, they are less demanding to handle and put on the board utilizing computerized pick-and-place machines. These machines can put thousands of components per hour, essentially diminishing the time it takes to gather a circuit board.

This effectiveness in manufacturing leads to decreased labour costs and speedier generation times, which is significant for companies that require to keep up with fast-paced Consumer hardware markets. Besides, the compact plan of SMT components too decreases the generally fetched of crude materials, contributing to lower manufacturing costs. The combination of these components makes SMT circuit boards a profoundly cost-effective arrangement for electronics manufacturers, especially for mass-produced Consumer products.

SMT’s Part in Driving Development in Electronics

As the request for littler, more proficient, and feature-rich electronics proceeds to rise, SMT Technology plays a central part in encouraging advancement over different businesses. Let’s see at a few particular ways SMT circuit boards are empowering cutting-edge progressions in electronics.

1. Miniaturization of Consumer Electronics

Consumer hardware, such as smart phones, smart watches, and portable workstations, are maybe the most self-evident cases of items profiting from SMT circuit boards. As Technology has progressed, the request for sleeker, more slender electronics with more capabilities has developed. SMT has empowered this miniaturization by permitting more components to be pressed into littler spaces, without relinquishing performance.

For illustration, the move from the bulky portable phones of the 1990s to the smooth smart phones of nowadays would not have been conceivable without SMT. Present day smart phones house an cluster of sensors, processors, and communication modules, all made conceivable by the utilize of surface mount components. With SMT, it’s conceivable to fit a huge number of progressed technologies—like multi-lens cameras, progressed processors, and touch screens—into a thin and lightweight phone.

2. Wearable Technology

Wearable electronics, such as wellness trackers, smart watches, and augmented reality (AR) glasses, have gotten to be fantastically prevalent in later a long time. These electronics require compact plans that can house a assortment of components, counting sensors, processors, and communication modules, all whereas being lightweight and comfortable for the client to wear. SMT circuit boards are basic in accomplishing this objective, as they permit for tall component thickness in exceptionally little packages.

For occurrence, in a smart watch, a circuit board might have components for GPS following, heart rate sensors, remote communication, and a battery, all stuffed into a space no greater than a wristwatch. Without the exactness and compactness of SMT, accomplishing this level of usefulness in such a little gadget would be impossible.

3. Medical Devices

In the Medical field, SMT is driving the improvement of more proficient and compact restorative electronics. These incorporate everything from versatile demonstrative devices to life-saving inserts. Restorative electronics are frequently required to be little, solid, and able of working in a assortment of situations, which makes SMT the perfect solution.

For case, the miniaturization of hearing helps and pacemakers has been made conceivable through the utilize of SMT circuit boards. These electronics require to be little sufficient to be comfortably worn or embedded but still require to perform complex assignments, such as checking imperative signs or preparing sound signals. SMT Technology empowers these electronics to be both compact and profoundly functional.

4. Internet of Things (IoT)

The rise of the Web of Things (IoT) has made a request for a endless number of interconnected electronics that are little, energy-efficient, and cost-effective. Whether it’s savvy indoor regulators, associated fridges, or mechanical sensors, all of these electronics require progressed, compact circuit boards to work successfully. SMT circuit boards are culminate for this application, as they permit manufacturers to pack more usefulness into littler and more reasonable devices.

As IoT electronics multiply over industries—from smart homes to horticulture to manufacturing—SMT will proceed to play a basic part in guaranteeing these electronics are as compact and energy-efficient as possible.

The Future of SMT Circuit Boards

The future of SMT Technology looks promising, with proceeded headways likely to assist improve the capabilities of compact hardware. The continuous drift toward miniaturization and expanded usefulness in Consumer and mechanical electronics will as it were increment the request for SMT circuit boards.

Future developments may incorporate indeed littler components, made strides materials for superior warm scattering, and more progressed manufacturing strategies that diminish costs and progress generation times. Furthermore, as 5G, AI, and other rising advances proceed to shape the electronics scene, SMT will be at the bleeding edge of guaranteeing that these advancements can be joined into littler and more productive devices.

Conclusion

Surface Mount Technology has revolutionized the plan and manufacturing of circuit boards, playing a essential part in the improvement of compact and productive electronics. By empowering littler, more solid, and higher-performing electronics, SMT has opened the entryway to endless developments over businesses, from Consumer hardware to Medical electronics and the Web of Things. As request for miniaturization and expanded usefulness proceeds to rise, SMT will stay an basic Technology in forming the future of advanced electronics. The proceeded advancement of SMT will without a doubt lead to indeed more compact, proficient, and effective electronics, driving mechanical progression in the a long time to come.