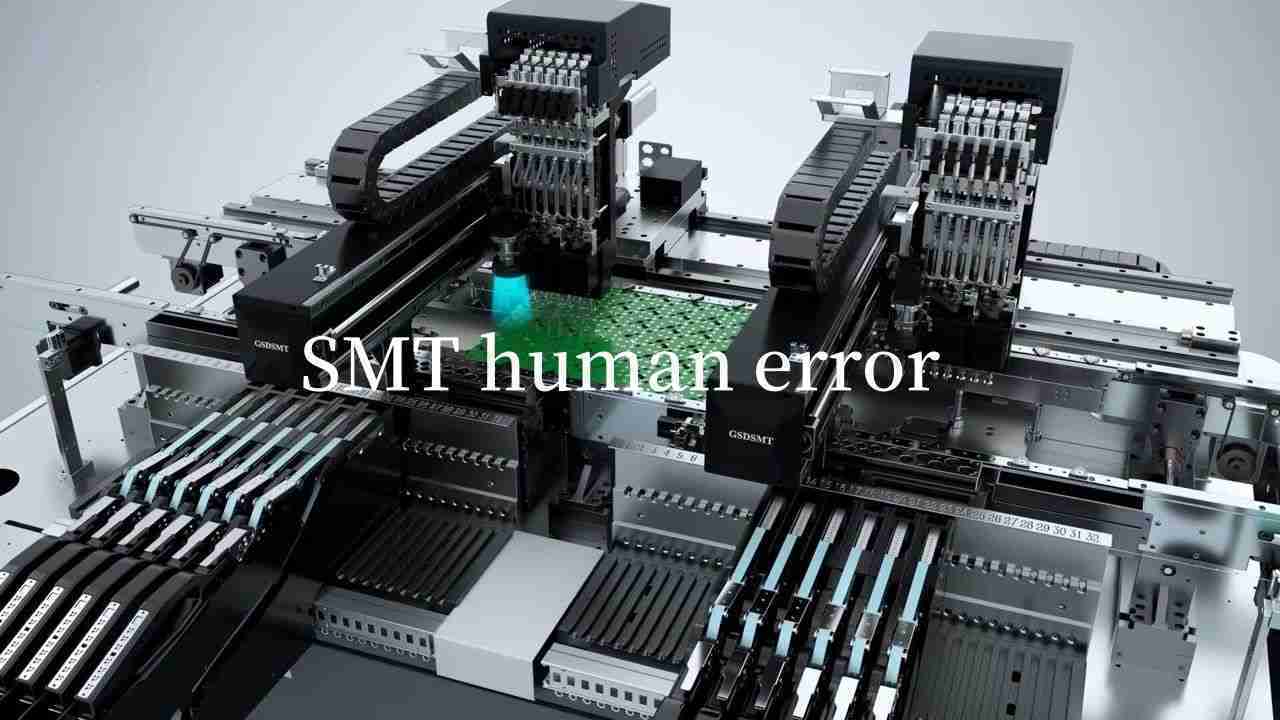

The SMT pick and place machine is the core equipment in the SMT mount processing. Before loading the material into the placement machine, the material must be prepared correctly to ensure the placement quality.

Be careful when loading to avoid damaging the material or equipment.

The reason for SMT assembly material error

1.Negligence:

Employees can be careless at work for a variety of reasons.

Due to fatigue and lack of rest, alertness decreases, so it is easy to make mistakes.

Additionally, distraction or lack of attention can also lead to inattention.

The mind loses focus when there are external distractions, leading to negligence.

2.Improper training or insufficient skills:

Employees may make mistakes because of a lack of training or insufficient skill levels.

It can also lead to work quality reduction, unhappy customers, and possibly accidents.

3.Time management issues:

Time management issues can cause employees to work under tight time pressures, increasing the risk of making mistakes.

When employees feel time-poor, they may rush to complete tasks without thinking through the details.

4.Poor working environment:

A poor PCBA factory work environment includes noisy, crowded, or unstable factors, which can distract employees and make it difficult to concentrate, leading to errors.

5.Lack of quality awareness:

There is a lack of quality awareness, insufficient attention to quality, failure to check carefully, or ignoring quality standards.

These situations may lead to the production of defective products, increasing the risk of subsequent problems.

6.Internal communication issues:

Poor communication among internal staff and unclear instructions can lead to misunderstandings, confusion, and error to occur.

Therefore, good internal communication and clear work instructions are significant to avoid mistakes.

Improve strategy

1.Increase employees’ rest and training opportunities to avoid excessive fatigue.

Develop employees’ focus and concentration, for example, through training or mental health support.

Establish clear workflows and standard operating procedures to ensure employees don’t miss critical steps.

Encourage employees to use reminder tools and time management techniques to stay alert and focused.

2.Formulate a clear work plan and schedule.

Reasonable working hours can reduce employees’ time pressure.

Reduce wasted time so that you can use your work time more efficiently.

3.Provide an appropriate working environment, including comfortable seating, proper lighting and ventilation, etc.

Providing a quiet, clean, and orderly working environment can reduce the possibility of environmental disturbances.

4.Establish effective quality control procedures to ensure that employees follow the correct steps and processes in operations.

Provide comprehensive training programs and formulate standard SOP operating procedures and quality control standards.

5.Encourage employee communication and feedback. Encourage employees to seek feedback, continuously learn, and improve their skills.

Summary

The main reasons for employee errors in the SMT (Surface Mount Technology) field include negligence, improper training or inadequate skills, time management issues, poor working environment, lack of quality awareness, and internal communication problems.

Take a series of measures to improve these problems, including adequate rest and training of operating skills, making detailed production plans, providing a suitable PCBA factory environment, establishing quality control procedures, encouraging employee communication and feedback, and improving quality awareness.

These measures can help reduce SMT human errors and improve work efficiency and product quality.

Refined management and quality control are crucial in SMT assembly, so it is significant support and training for employees.