Comprehensive Guide to Printed Circuit Board (PCB) Services, Electronic Components, and Trusted Suppliers

In the energetic world of gadgets, Printed Circuit Boards (PCBs) play a significant part in supporting and interfacing components to make useful gadgets. From regular customer gadgets to complex mechanical apparatus, PCBs frame the spine of essentially each electronic gadget we utilize nowadays. The PCB market is booming, and with progressions in technology, services related to PCB plan, assembly, and supply have ended up profoundly specialized and basic to the advancement of solid electronic devices.

This article explores the fundamental angles of PCB services, sorts of electronic Boards, the part ofcomponent distributors, and key contemplations for sourcing components from legitimate suppliers.

1. The Significance of Printed Circuit Board (PCB) Services

PCB services include everything from plan and prototyping to full-scale generation and testing of PCBs.

These services guarantee that the PCBs meet the required determinations, quality guidelines, and usefulness anticipated by producers and end-users. Let’s take a closer see at the sorts of PCB services available.

1) PCB Plan and Prototyping

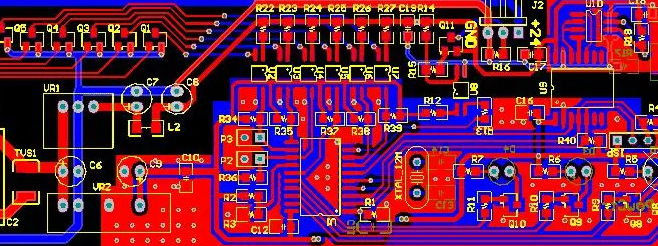

PCB plan and prototyping are the introductory and most basic stages in the PCB advancement prepare. Engineers plan the board format utilizing CAD (Computer-Aided Design) computer program, arranging the associations between different components.

Prototyping permits producers to test and refine PCB plans some time recently committing to full generation. Prototyping services regularly include:

• Schematic capture

• Layout and routing

• Design for manufacturing (DFM) checks

• Prototype testing and validation

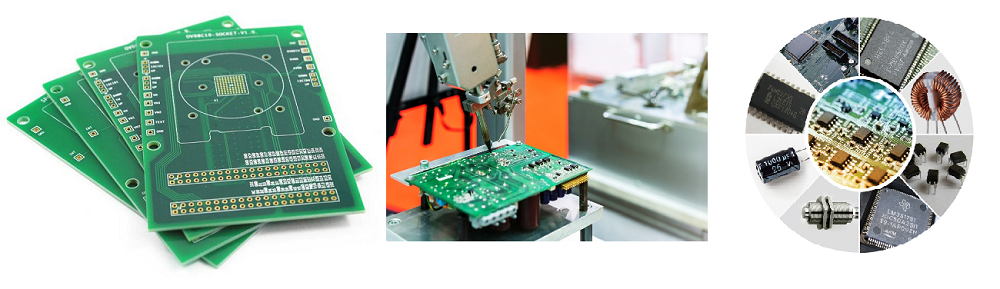

2) PCB Manufacturing

Manufacturing includes making the physical PCB utilizing different forms such as carving, plating, and fastening. Solid PCB manufacturing services guarantee that the Boards are manufactured to exact details, including:

• Material determination (FR4, CEM-1, etc)

• Layer setup (single-sided, double-sided, or multi-layer)

• Copper thickness and follow width

• Quality checks for solidness and conductivity

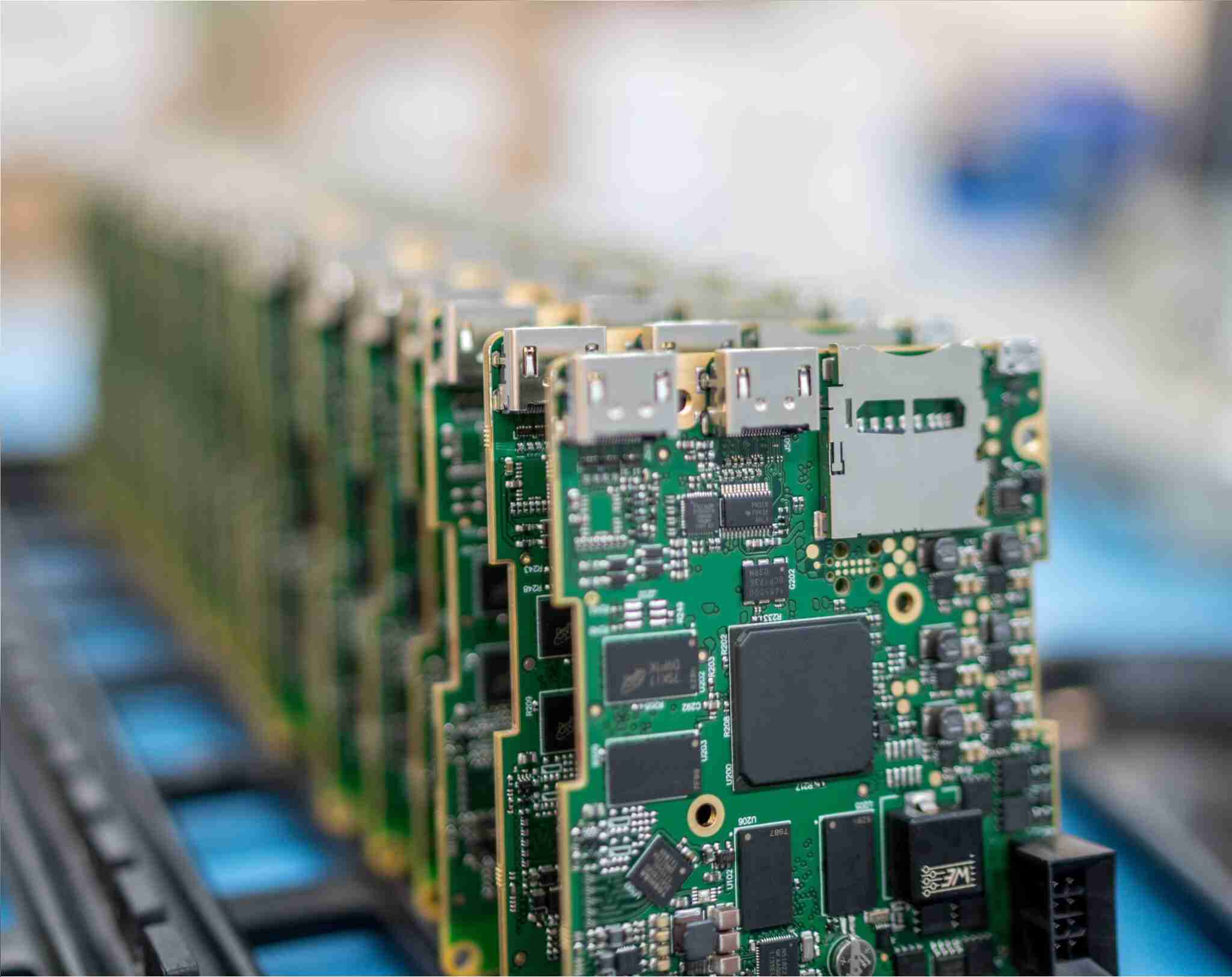

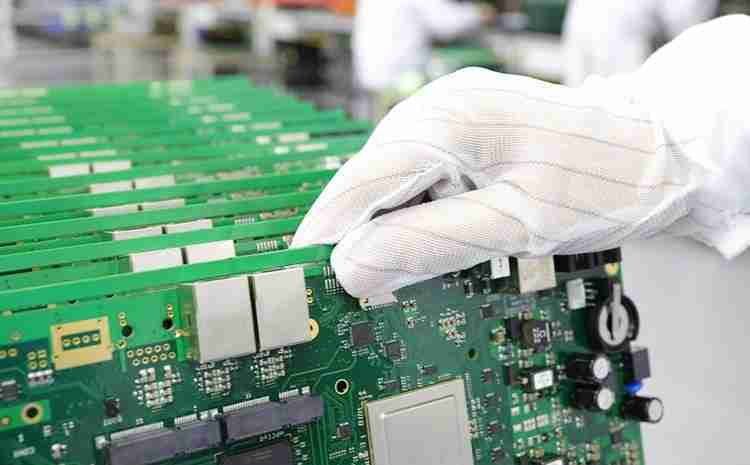

3) PCB Assembly Services

PCB assembly (PCBA) includes putting and fastening components onto the PCB. This benefit is significant for guaranteeing precise component situation, arrangement, and patching quality. Key services in PCBA include:

• Surface Mount Technology (SMT)

• Through-Hole Technology (THT)

• Hybrid assembly

• Inspection and testing

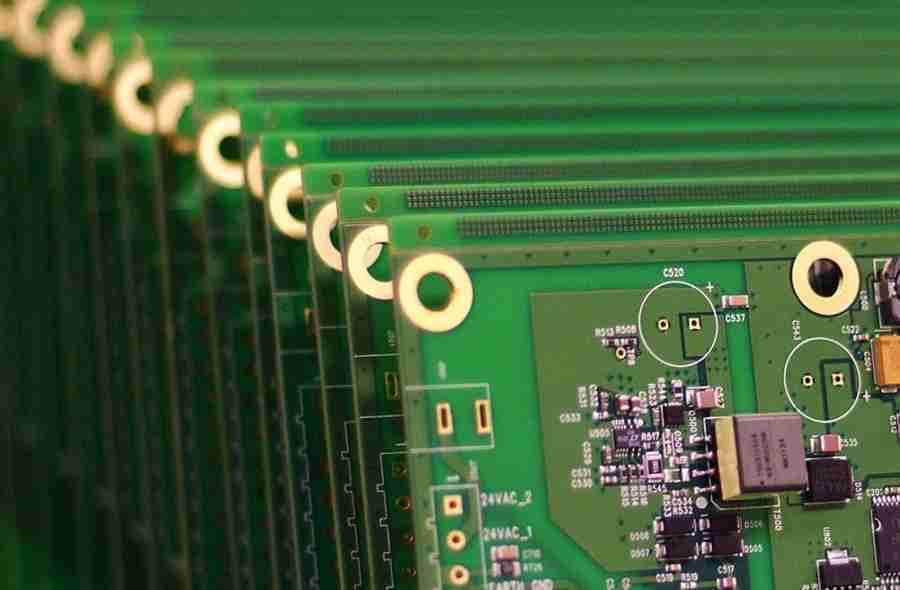

4) PCB Testing and Quality Assurance

Testing is an necessarily portion of PCB services to guarantee the unwavering quality and execution of the board. Common testing strategies include:

• In-circuit testing (ICT)

• Functional testing (FCT)

• Automated Optical Assessment (AOI)

• X-ray assessment for fastening defects

2. Sorts of Printed Circuit Boards and Their Applications

Electronic Boards are utilized in a wide run of applications, from shopper hardware to therapeutic gadgets and aviation technology. Here are a few common types:

1) Single-Layer PCBs

These are the least complex PCBs, comprising of a single layer of conductive fabric. They are ordinarily utilized in low-cost, high-volume applications like calculators, radios, and Driven lighting.

2) Double-Layer PCBs

Double-layer PCBs have conductive copper layers on both sides, which permits for a higher thickness of components and more complex circuits. They are commonly utilized in smart phones, control supplies, and testing equipment.

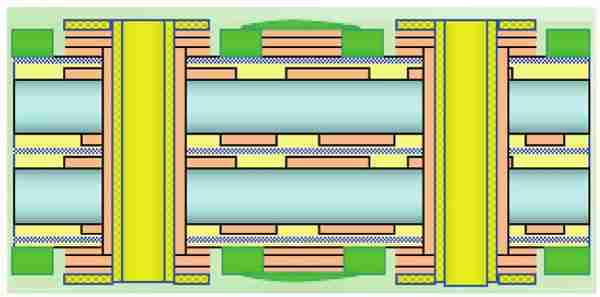

3) Multi-Layer PCBs

Multi-layer PCBs comprise of three or more layers, stacked together with protection fabric in between. They are broadly utilized in progressed hardware, such as computers, restorative gadgets, and car control frameworks, where space and complexity are pivotal factors.

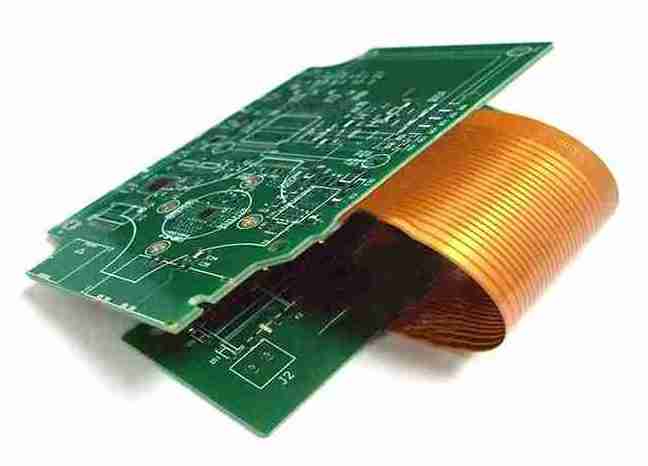

4) Flexible PCBs

Flexible PCBs utilize adaptable base materials, permitting them to twist and accommodate to distinctive shapes. They are commonly found in wearables, restorative gadgets, and compact customer electronics.

5) Rigid-Flex PCBs

Rigid-flex PCBs combine both inflexible and adaptable parts, advertising solidness and adaptability in a single board. These are basic in applications that require space optimization, such as military and aviation electronics.

3. Electronic Components and Their Part on a PCB

Every PCB is built with particular components, each serving a imperative part in the board’s usefulness.

Here are the fundamental sorts of electronic components:

1) Resistors

Resistors control the stream of current, playing a essential part in overseeing control dispersion over the circuit.

2) Capacitors

Capacitors store and discharge electrical vitality, which is fundamental in smoothing out voltage vacillations in a circuit.

3) Inductors

Inductors store vitality in a attractive field and are commonly utilized in control supplies to oversee current.

4) Diodes

Diodes permit current to stream in one course as it were, securing delicate components from potential harm due to invert polarity.

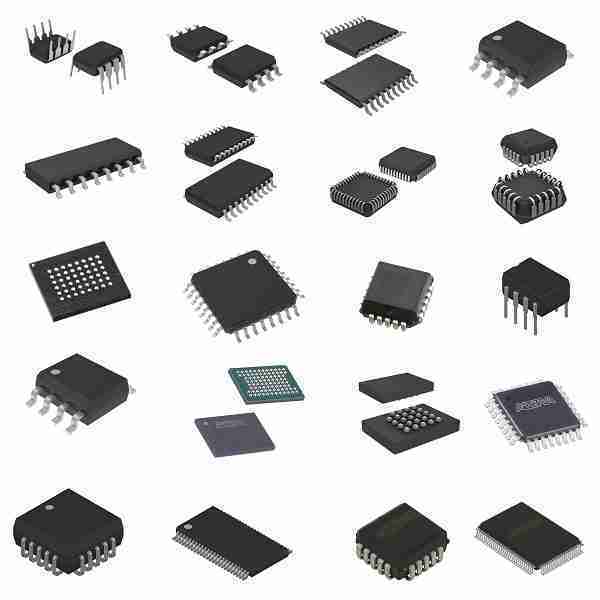

5) Integrated Circuits (ICs)

ICs are miniaturized circuits that perform a assortment of capacities, from essential intensification to complex handlinh. They are fundamental in advanced advanced gadgets, acting as the “brain” of the circuit.

6) Transistors

Transistors work as intensifiers and switches in electronic circuits, controlling the current stream and empowering flag modulation.

4. Part of Electronic Component Merchants and Suppliers

Distributors and providers play an basic part in the supply chain for PCB manufacturing, acting as mediators between component producers and customers.

1) Services Given by Component Distributors

Component merchants give different services past the simple supply of parts. These services regularly include:

• Inventory management

• Component sourcing and kitting

• Technical back and guidance

• Obsolescence management

• Supply chain flexibility

2) Benefits of Working with Reliable Suppliers

Partnering with dependable providers guarantees that producers get high-quality, veritable components.

This decreases dangers of fake parts, makes strides generation proficiency, and guarantees compliance with industry standards.

5. Key Parts When Selecting Electronic Component Suppliers

Choosing a provider is a vital choice that impacts the whole generation lifecycle. Here are a few fundamental variables to consider:

1) Quality Confirmation and Certifications

Suppliers ought to follow to industry measures, such as ISO 9001 or AS9100, guaranteeing that components meet exacting quality requirements.

2) Item Accessibility and Lead Times

The supplier’s stock levels and lead times are significant, particularly for producers with tight plans and high-volume orders.

3) Estimating and Cost-Effectiveness

Cost is a noteworthy figure, but quality ought to not be compromised. It’s prudent to discover providers who offer competitive estimating without relinquishing component reliability.

4) Technical Support and Expertise

Some providers give specialized back and counsel, which can be profoundly important, particularly for complex or custom components.

5) Counterfeit Component Mitigation

A dependable provider ought to have forms to identify and relieve fake components, guaranteeing the realness of each part.

6. Advancements in PCB Services and Component Supply Chain

The fast pace of innovative headway has altogether affected PCB services and the electronic components supply chain. Advancements in materials, plan, and manufacturing forms proceed to reshape the industry.

1) Advancements in PCB Materials

Traditionally, PCB materials have fundamentally included fiberglass (FR4) and copper. In any case, unused materials like ceramic-based PCBs, metal-core PCBs, and adaptable polymers have presented upgraded strength, warm dissemination, and adaptability. These materials are fundamental for applications in businesses such as car, aviation, and military hardware, where natural push and tall

temperatures are common.

2) Mechanized and AI-Driven PCB Design

Artificial insights (AI) and machine learning (ML) are changing PCB plan, permitting for speedier and more productive formats. AI-driven plan computer program can optimize formats to minimize vitality utilization, oversee warm way better, and diminish by and large generation costs. Computerized PCB plan moreover empowers a quicker turnaround time, profiting businesses where speed is basic, such as customer hardware and telecommunications.

3) 3D Printing for Quick PCB Prototyping

3D printing, or added substance manufacturing, has ended up a profitable instrument for quick PCB prototyping. 3D-printed PCBs permit originators to rapidly create and test board formats, diminishing the lead time from plan to generation. This technology too permits for complex and offbeat board shapes, advantageous for wearable tech, miniaturized restorative gadgets, and other custom applications.

4) Internet of Things (IoT) and PCBs

As the Web of Things (IoT) proceeds to develop, so does the request for little, power-efficient, and vigorous PCBs. IoT gadgets regularly work in inaccessible areas or in portable situations, which require PCBs that can handle shifted and in some cases unforgiving conditions whereas keeping up vitality productivity. PCBs utilized in IoT gadgets are regularly compact, and they use remote modules for

communication, driving the require for littler, multi-functional PCBs.

5) Natural Contemplations in PCB Production

Environmental supportability has gotten to be a need for numerous PCB producers. Eco-friendly hones such as utilizing lead-free patch, recyclable materials, and energy-efficient generation forms are getting to be more common. Compliance with guidelines like RoHS (Confinement of Dangerous Substances) and WEEE (Squander Electrical and Electronic Gear) reflects a commitment to decreasing the natural affect of PCB production.

7. How to Assess PCB Benefit Suppliers and Component Distributors

Choosing the right PCB benefit supplier and component wholesaler can make a critical distinction in the quality, strength, and usefulness of electronic items. Here are a few assessment criteria to consider when selecting partners:

1) Quality of Services

Assess the benefit provider’s quality control forms. Dependable suppliers frequently execute thorough testing and assessment methods, such as Automated Optical Inspection (AOI) and In-Circuit Testing (ICT), to guarantee Boards are free from surrenders. Certifications such as ISO 9001, ISO 13485 (for restorative gadgets), and AS9100 (for aviation) are great pointers of a quality-focused benefit provider.

2) Reputation and Client Portfolio

The notoriety of a PCB producer or component wholesaler can offer knowledge into their unwavering quality. See for suppliers with a history of fruitful ventures and positive client input. Numerous legitimate companies will exhibit case thinks about or a client portfolio that illustrates their involvement in dealing with assorted, industry-specific projects.

3) Technological Capabilities

Modern PCB services ought to have up-to-date hardware and innovative capabilities, counting SMT machines, pick-and-place robots, and progressed fastening hardware A few progressed benefit suppliers moreover offer cross breed PCBs, which combine diverse materials for included usefulness, such as warm

administration for control electronics.

4) Flexibility and Customization Options

Flexibility is basic, especially for producers that require custom Boards or specialized components. A supplier that offers custom PCB plan, materials, and component arrangement choices will be more versatile to interesting requirements.

5) Compliance with Industry Standards

A legitimate PCB and component provider ought to comply with benchmarks important to their industry, such as:

• IPC-A-610: Guidelines for hardware assembly.

• IPC-2221: Common guidelines for PCB design.

• RoHS and REACH: Benchmarks constraining unsafe substances in components. Compliance with these guidelines illustrates a commitment to quality and safety.

8. Patterns in Electronic Component Conveyance and Sourcing

The electronic component supply chain has advanced essentially over the final decade With expanding worldwide request, modern patterns have risen that are forming the dispersion and sourcing landscape:

1) Component Deficiencies and Supply Chain Resilience

The hardware industry has confronted component deficiencies in later a long time, especially with semiconductors. Solid providers are presently centering on building more strong supply chains, utilizing multi-sourcing procedures, and keeping up higher stock levels to meet request and maintain a strategic distance from disruptions.

2) Just-in-Time (JIT) Stock and Logistics

The JIT demonstrate minimizes stock costs and adjusts supply with generation plans. Whereas this approach can decrease costs, it too requires a exceedingly dependable supply chain. Providers and merchants who exceed expectations at JIT stock administration frequently have modern coordinations frameworks, making a difference producers maintain a strategic distance from delays and diminish capacity expenses.

3) Rise of Online Component Marketplaces

Digital marketplaces for electronic components have rearranged sourcing by advertising moment get to to parts and real-time stock upgrades. These stages permit producers to rapidly discover components, compare costs, and confirm portion genuineness, giving a helpful arrangement for both huge and little manufacturers.

4) Counterfeit Detection and Traceability

With the increment in fake components entering the advertise, legitimate wholesalers are utilizing progressed location and traceability strategies. These incorporate serialization, blockchain for traceability, and visual confirmation strategies. Wholesalers with strong anti-counterfeiting measures secure producers from getting substandard or fake parts.

5) Component Out of date quality Management

Components frequently gotten to be out of date as more current forms are presented. Dependable providers offer out of date quality administration services, making a difference producers oversee end-of-life components by giving substitution parts, last-time-buy openings, or prompting on plan changes. This is particularly basic in businesses such as aviation and defense, where component lifecycle administration is fundamental.

9. The Future of PCB Services and Component Supply

The future of PCB Services and electronic component conveyance is promising, with numerous progressions pointed at expanding productivity, quality, and sustainability.

1) Automation and Robotics in PCB Assembly

Automation is anticipated to play an indeed bigger part in PCB assembly, with mechanical technology taking on errands like patching, review, and component arrangement. Mechanical robotization not as it were upgrades exactness but moreover permits producers to increment generation capacity without

relinquishing quality.

2) IoT-Enabled Smart Manufacturing

IoT innovations are finding applications in PCB manufacturing IoT sensors implanted in manufacturing gear give real-time information on machine execution, empowering prescient support and minimizing downtime IoT in PCB manufacturing moves forward proficiency, quality control, and vitality management.

3) Development of Eco-Friendly PCB Options

As natural concerns develop, producers are investigating eco-friendly PCB materials and generation procedures. Alternatives like biodegradable materials, lead-free patch, and low-toxicity inks are likely to ended up more common. The industry is moreover moving toward plans that permit for simpler reusing and transfer of PCB components.

4) On-Demand PCB Prototyping Services

On-demand prototyping Services utilizing progressed manufacturing strategies such as 3D printing will proceed to pick up footing. These Services offer speedy turnaround times, permitting architects to make and test modern plans quicker, which is especially valuable for new businesses and little businesses working on inventive hardware projects.

5) Collaborative Associations Over the Supply Chain

Collaboration over the hardware supply chain—from PCB originators to component suppliers—is getting to be more vital. By building up long-term organizations, companies can upgrade item advancement, optimize stock administration, and diminish lead times, eventually driving a more spry and strong supply chain.

Conclusion

Printed Circuit Board Services and electronic component providers are at the heart of the quickly advancing gadgets industry. As technology advances require for solid, high-quality PCBs and true components develops more grounded. From PCB design and assembly to finding trusted wholesalers, each organize of the PCB lifecycle requires consideration to quality, flexibility, and efficiency.

Selecting the right PCB service provider and components distributor not as it were guarantees the toughness and execution of electronic items but moreover contributes to the in general victory and development potential of a company. With proceeded headways in materials, manufacturing, and coordinations, the PCB and electronic component businesses are well-positioned to bolster the following wave of innovative advancement, from IoT to AI-driven gadgets and past.

Latest Blog

Table of Content

Contcat Us

Phone: +86-18123905375

Email: sales@circuitcardassembly.com

Skype: ali_youte

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Afrikaans

Afrikaans Shqip

Shqip አማርኛ

አማርኛ العربية

العربية Հայերեն

Հայերեն Azərbaycan dili

Azərbaycan dili Euskara

Euskara Беларуская мова

Беларуская мова বাংলা

বাংলা Bosanski

Bosanski Български

Български Català

Català Cebuano

Cebuano Chichewa

Chichewa 简体中文

简体中文 繁體中文

繁體中文 Corsu

Corsu Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Esperanto

Esperanto Eesti

Eesti Filipino

Filipino Suomi

Suomi Français

Français Frysk

Frysk Galego

Galego ქართული

ქართული Deutsch

Deutsch Ελληνικά

Ελληνικά ગુજરાતી

ગુજરાતી Kreyol ayisyen

Kreyol ayisyen Harshen Hausa

Harshen Hausa Ōlelo Hawaiʻi

Ōlelo Hawaiʻi עִבְרִית

עִבְרִית हिन्दी

हिन्दी Hmong

Hmong Magyar

Magyar Íslenska

Íslenska Igbo

Igbo Bahasa Indonesia

Bahasa Indonesia Gaeilge

Gaeilge Italiano

Italiano 日本語

日本語 Basa Jawa

Basa Jawa ಕನ್ನಡ

ಕನ್ನಡ Қазақ тілі

Қазақ тілі ភាសាខ្មែរ

ភាសាខ្មែរ 한국어

한국어 كوردی

كوردی Кыргызча

Кыргызча ພາສາລາວ

ພາສາລາວ Latin

Latin Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba Lëtzebuergesch

Lëtzebuergesch Македонски јазик

Македонски јазик Malagasy

Malagasy Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം Maltese

Maltese Te Reo Māori

Te Reo Māori मराठी

मराठी Монгол

Монгол ဗမာစာ

ဗမာစာ नेपाली

नेपाली Norsk bokmål

Norsk bokmål پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português ਪੰਜਾਬੀ

ਪੰਜਾਬੀ Română

Română Русский

Русский Samoan

Samoan Gàidhlig

Gàidhlig Српски језик

Српски језик Sesotho

Sesotho Shona

Shona سنڌي

سنڌي සිංහල

සිංහල Slovenčina

Slovenčina Slovenščina

Slovenščina Afsoomaali

Afsoomaali Español

Español Basa Sunda

Basa Sunda Kiswahili

Kiswahili Svenska

Svenska Тоҷикӣ

Тоҷикӣ தமிழ்

தமிழ் తెలుగు

తెలుగు ไทย

ไทย Türkçe

Türkçe Українська

Українська اردو

اردو O‘zbekcha

O‘zbekcha Tiếng Việt

Tiếng Việt Cymraeg

Cymraeg isiXhosa

isiXhosa יידיש

יידיש Yorùbá

Yorùbá Zulu

Zulu