First piece quality control for SMT assembly

SMT patch assembly is a vital process in the manufacturing process of electronic products, and its quality directly affects the performance and reliability of the final product.

Control first piece quality is a significant part of PCB SMT patch assembly quality control and is the key to ensuring product quality.

The purpose of the first piece of quality control

The purpose of first-item quality control is to detect and eliminate defects that affect product quality by conducting comprehensive testing and inspection on the first piece to ensure that the products meet customer requirements.

The first piece of quality control content

The content of first-article quality control mainly includes the following aspects:

1) Material inspection

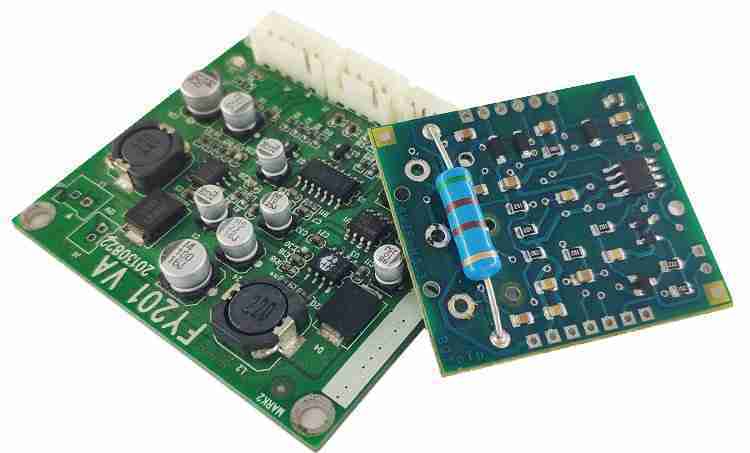

Check the electronic components, PCB boards, and solder paste used to ensure they meet product requirements

2) Process inspection

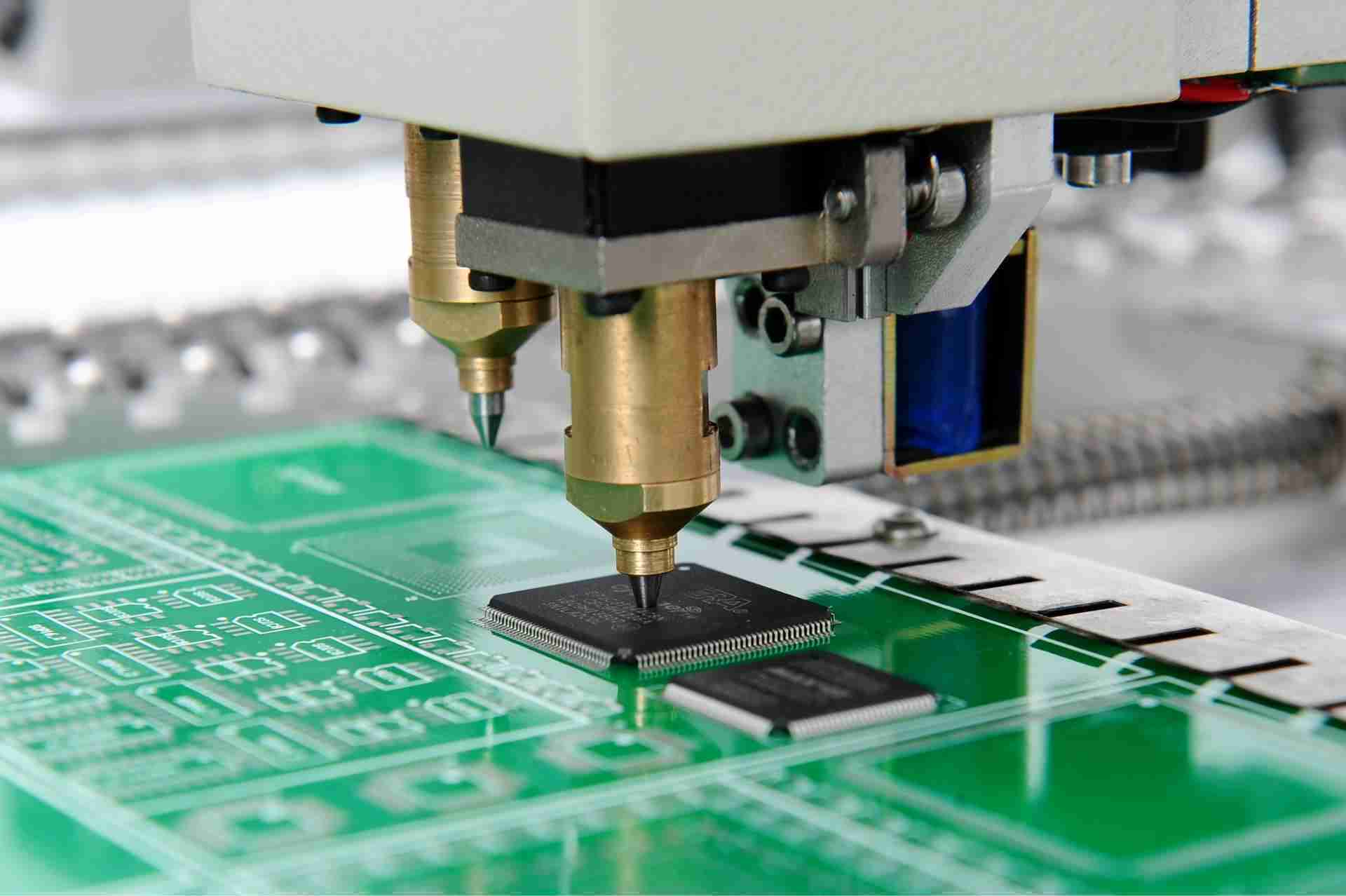

Check the SMT placement machine, reflow oven, and other equipment to ensure they are in good condition.

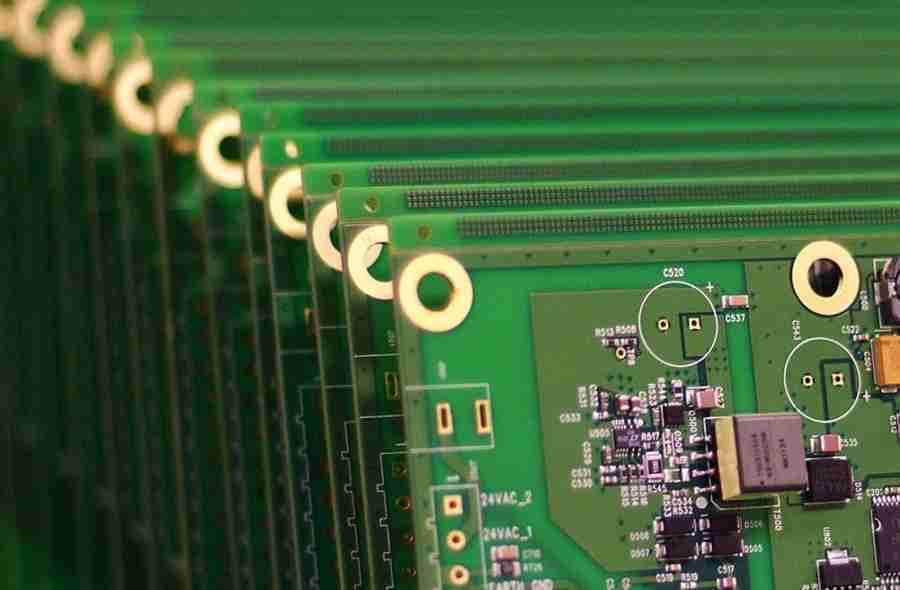

3) Mounting quality inspection

Check the part’s position, angle, and polarity to ensure they meet the drawing requirements.

4) Welding quality inspection

Check the solder joint’s shape, size, and strength to ensure they meet the requirements.

First Article Quality Control Method

The main methods of first-article quality control are as follows:

1) Visual inspection

Visual inspection can find defects such as incorrect component position and poor solder joint shape.

2) First Article Tester

using testing instruments to test the product can find defects, for example, insufficient solder joint strength and incorrect component parameters.

Our Circuitcardassembly TFT350 first article tester has obtained many national patents and has always been in the leading position in SMT testing.

3) X-ray inspection

Use X-ray inspection equipment to inspect products and find internal defects such as Components installed incorrectly and voids.

First Article Quality Control Process

We at Circuitcardassembly have implemented a strict quality control process in terms of first-piece quality control;

The process we follow is as follows

1. Open the MES system and inquire about the order according to the label order number.

2. Check the original documents and production notes in the order information.

3. Double-click in the production BOM’s the machine model to open the engineering data.

4. Download the SMT placement program, and open it, copy the BOM and coordinates.

5.Enter the test, open the program, load the desktop picture, and fill in the furnace temperature for testing.

6. After testing the capacitance and resistance, check the material polarity of the drawings.

7.After completing the test and polarity check, click finish test and select the test result.

8.Notify production of test results and conduct the first piece past the furnace.

9.After passing through the furnace, check the product’s furnace passing effect, tinning, deviation, whether the tin is melted, etc.

10. Hang the first piece of identification card and send it for sample production.

First Article Quality Control Considerations

When conducting first-article quality control, you should pay attention to the following points:

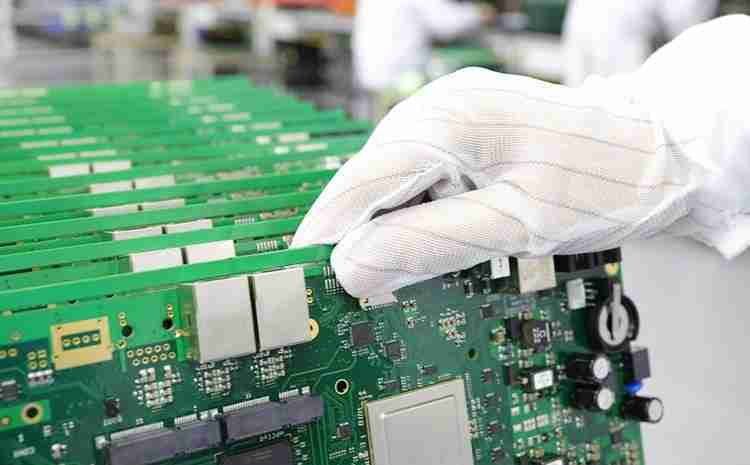

• First article quality control should be performed by experienced personnel.

• First piece quality control should be carried out strictly following the standards.

• First-article quality control should detect and eliminate defects promptly.

The significance of the first article quality control

First-article quality control is a significant means to ensure product quality. It can effectively prevent the production of batch defective products.

By conducting comprehensive testing and inspection on the first article, defects that affect product quality can be discovered and eliminated, ensuring that the product meets customer requirements.

In conclusion

SMT patch processing is the key to ensuring product quality. We should attract attention.

By strictly following the standards for first-piece quality control, we can effectively prevent batch defective products and ensure product quality.

Latest Blog

Table of Content

Contcat Us

Phone: +86-18123905375

Email: sales@circuitcardassembly.com

Skype: ali_youte

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Afrikaans

Afrikaans Shqip

Shqip አማርኛ

አማርኛ العربية

العربية Հայերեն

Հայերեն Azərbaycan dili

Azərbaycan dili Euskara

Euskara Беларуская мова

Беларуская мова বাংলা

বাংলা Bosanski

Bosanski Български

Български Català

Català Cebuano

Cebuano Chichewa

Chichewa 简体中文

简体中文 繁體中文

繁體中文 Corsu

Corsu Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Esperanto

Esperanto Eesti

Eesti Filipino

Filipino Suomi

Suomi Français

Français Frysk

Frysk Galego

Galego ქართული

ქართული Deutsch

Deutsch Ελληνικά

Ελληνικά ગુજરાતી

ગુજરાતી Kreyol ayisyen

Kreyol ayisyen Harshen Hausa

Harshen Hausa Ōlelo Hawaiʻi

Ōlelo Hawaiʻi עִבְרִית

עִבְרִית हिन्दी

हिन्दी Hmong

Hmong Magyar

Magyar Íslenska

Íslenska Igbo

Igbo Bahasa Indonesia

Bahasa Indonesia Gaeilge

Gaeilge Italiano

Italiano 日本語

日本語 Basa Jawa

Basa Jawa ಕನ್ನಡ

ಕನ್ನಡ Қазақ тілі

Қазақ тілі ភាសាខ្មែរ

ភាសាខ្មែរ 한국어

한국어 كوردی

كوردی Кыргызча

Кыргызча ພາສາລາວ

ພາສາລາວ Latin

Latin Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba Lëtzebuergesch

Lëtzebuergesch Македонски јазик

Македонски јазик Malagasy

Malagasy Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം Maltese

Maltese Te Reo Māori

Te Reo Māori मराठी

मराठी Монгол

Монгол ဗမာစာ

ဗမာစာ नेपाली

नेपाली Norsk bokmål

Norsk bokmål پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português ਪੰਜਾਬੀ

ਪੰਜਾਬੀ Română

Română Русский

Русский Samoan

Samoan Gàidhlig

Gàidhlig Српски језик

Српски језик Sesotho

Sesotho Shona

Shona سنڌي

سنڌي සිංහල

සිංහල Slovenčina

Slovenčina Slovenščina

Slovenščina Afsoomaali

Afsoomaali Español

Español Basa Sunda

Basa Sunda Kiswahili

Kiswahili Svenska

Svenska Тоҷикӣ

Тоҷикӣ தமிழ்

தமிழ் తెలుగు

తెలుగు ไทย

ไทย Türkçe

Türkçe Українська

Українська اردو

اردو O‘zbekcha

O‘zbekcha Tiếng Việt

Tiếng Việt Cymraeg

Cymraeg isiXhosa

isiXhosa יידיש

יידיש Yorùbá

Yorùbá Zulu

Zulu