In the cutting edge period of mechanical advancement, electronics play a essential part in forming businesses and changing ordinary life. At the heart of each electronic gadget lies a basic component that makes usefulness and effectiveness conceivable: the printed circuit board (PCB). PCB board assembly, moreover known as circuit card assembly or PCBA (printed circuit board assembly), has revolutionized electronic manufacturing, empowering the generation of modern, solid, and compact electronics. This Content investigates how PCB board assembly has gotten to be the foundation of advanced electronic manufacturing and its affect on the industry.

The Part of PCB Board Assembly in Electronics

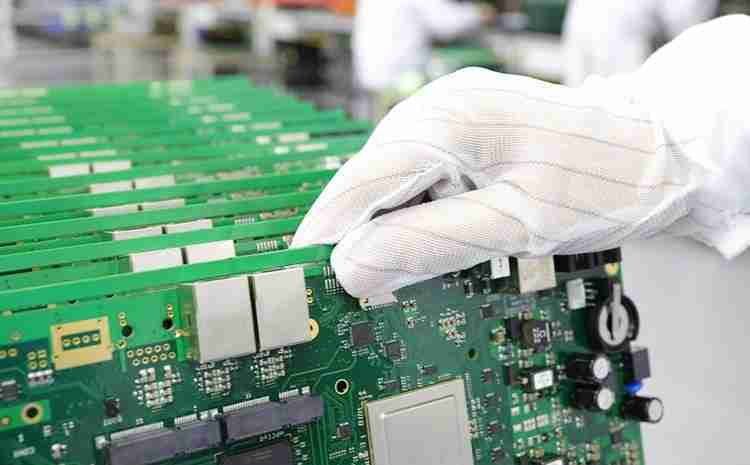

PCB board assembly includes the integration of electronic components onto a uncovered PCB to make a utilitarian circuit board. This handle combines exactness, progressed technology, and talented building to guarantee that the last item meets high-quality measures. Without PCB board assembly, manufacturing electronic electronics like shrewd phones, restorative hardware, car frameworks, and domestic apparatuses would be inconceivable at the scale and effectiveness required by today’s consumers.

Circuit Card Assembly has streamlined the manufacturing prepare by supplanting conventional wiring strategies with a more productive and solid arrangement. It not as it were decreases the estimate of electronics but moreover improves their execution and toughness. The integration of PCBA circuit sheets into items guarantees reliable operation, minimizes manual blunders, and permits for mass generation with tall levels of precision.

Key Steps in PCB Board Assembly

The PCB Board Assembly prepare includes a few basic steps that contribute to the creation of utilitarian circuit sheets. Each organize requests fastidious consideration to detail and the utilize of progressed equipment:

1. Solder Glue Application: The handle starts with the application of patch glue onto the uncovered PCB. This glue, made from a blend of powdered patch and flux, is connected to particular zones where components will be put. Exactness stencils are utilized to guarantee precise placement.

2. Component Situation: Surface mount technology (SMT) machines are utilized to put electronic components onto the PCB. These machines work with extraordinary speed and precision, guaranteeing that indeed the littlest components are situated correctly.

3. Soldering: After the components are set, the board goes through a reflow broiler where the patch glue is softened, making secure associations between the components and the PCB. In a few cases, wave fastening is utilized for through-hole components.

4. Inspection and Testing: Once patching is total, the PCB experiences assessment and testing to confirm its usefulness. Automated optical inspection (AOI), X-ray assessment, and useful testing are utilized to recognize any surrenders or irregularities.

5. Final Assembly: After passing quality checks, the PCB is coordinates into the last item. This may include extra assembly, wiring, or casing some time recently the gadget is prepared for use.

Each of these steps in PCB board assembly is pivotal for guaranteeing the unwavering quality and execution of electronic devices.

Transformative Benefits of PCB Board Assembly

PCB board assembly has altogether changed electronic manufacturing by conveying a few key benefits:

1. Enhanced Miniaturization: One of the most striking impacts of PCB board assembly is the capacity to miniaturize electronic electronics. With the utilize of progressed methods such as surface mount technology (SMT), producers can put littler components onto compact PCBs, empowering the creation of lightweight and versatile electronics.

2. Improved Unwavering quality: PCBA circuit sheets are outlined and gathered with exactness, decreasing the hazard of human mistake and guaranteeing reliable execution. Robotized forms like AOI and X-ray review guarantee that each board meets exacting quality benchmarks, coming about in items that are profoundly solid and durable.

3. Increased Productivity: Circuit card assembly permits producers to create expansive amounts of electronic electronics at a speedier rate. Computerization and streamlined workflows minimize generation time whereas keeping up precision, making it conceivable to meet the requests of a fast-paced market.

4. Cost-Effectiveness: By diminishing they require for manual labor and optimizing the utilize of materials, PCB board assembly brings down generation costs. Furthermore, the tall unwavering quality of PCBA circuit sheets minimizes the probability of absconds, diminishing they require for expensive repairs or replacements.

5. Customization: PCB board assembly underpins the customization of electronic electronics to meet particular necessities. Producers can plan circuit card assemblys custom fitted to special applications, whether for customer hardware, therapeutic electronics, aviation frameworks, or mechanical automation.

Applications of PCBA Circuit Boards

The flexibility and proficiency of PCB board assembly have made it an indispensably portion of different businesses. Here are a few cases of its applications:

1. Consumer Electronics: From keen phones and portable workstations to shrewd observes and gaming comforts, customer electronics depend intensely on PCBA Circuit Board for their usefulness. The miniaturization empowered by PCB board assembly permits producers to pack progressed highlights into compact designs.

2. Medical Electronics: In the healthcare industry, accuracy and unwavering quality are foremost. PCB board assembly is utilized in restorative hardware such as MRI machines, pacemakers, and symptomatic devices, guaranteeing exact and reliable operation.

3. Automotive Frameworks: Advanced vehicles are prepared with various electronic frameworks, counting route, excitement, security highlights, and motor control. PCB board assembly plays a basic part in manufacturing these components, upgrading vehicle execution and safety.

4. Industrial Mechanization: In mechanical settings, PCBA circuit sheets are utilized in control frameworks, mechanical autonomy, and apparatus. These applications require strong and high-performance circuit card assembly to guarantee smooth and productive operations.

5. Aerospace and Defence: The aviation and defence divisions request exceedingly dependable and solid electronic frameworks. PCB board assembly is utilized to make circuit card assemblies that meet the thorough guidelines required for applications in satellites, radar frameworks, and military equipment.

Advancements in PCB Board Assembly

The persistent advancement of technology has driven to critical headways in PCB board assembly, encourage changing electronic manufacturing:

1. High-Density Interconnect (HDI) Technology: HDI technology empowers the generation of PCBs with higher component densities, permitting for more compact and productive plans. This progression is especially profitable in applications where space is limited.

2. Flexible and Rigid-Flex PCBs: Adaptable PCBs and rigid-flex PCBs give more prominent plan flexibility, empowering the creation of electronics with interesting shapes and setups. These developments are broadly utilized in wearable technology and aviation applications.

3. Lead-Free Assembly: In reaction to natural concerns, numerous producers have received lead-free PCB board assembly forms. This move guarantees compliance with controls such as RoHS (Confinement of Unsafe Substances) whereas keeping up tall execution and reliability.

4. Advanced Testing Strategies: The advancement of advanced testing strategies, counting 3D AOI and mechanized utilitarian testing, has moved forward the precision and effectiveness of quality control forms in PCB board assembly.

5. Internet of Things (IoT) Integration: As IoT electronics ended up progressively predominant, PCB board assembly has adjusted to meet the requests of these interconnected frameworks. PCBA circuit sheets are outlined to bolster remote communication, moo control utilization, and compact designs.

Challenges and Future Trends

While PCB board assembly has changed electronic manufacturing, it is not without challenges. The expanding complexity of plans, request for miniaturization, and require for economical hones show continuous deterrents for producers. Be that as it may, the industry is balanced to overcome these challenges through development and innovative advancements.

Future patterns in PCB board assembly incorporate the appropriation of artificial intelligence (AI) and machine learning for handle optimization, the utilize of 3D printing for quick prototyping, and the investigation of progressed materials for improved execution. These advancements will proceed to drive the advancement of electronic manufacturing, guaranteeing that PCB board assembly remains at the cutting edge of technology.

Conclusion

PCB board assembly, or circuit card assembly, has revolutionized electronic manufacturing by empowering the generation of solid, effective, and compact electronics. From customer electronics to aviation frameworks, PCBA circuit sheets are fundamentally to a wide run of applications. The headways in technology and forms have advance improved the capabilities of PCB board assembly, making it a foundation of advanced manufacturing. As the industry proceeds to advance, PCB board assembly will play a imperative part in forming the future of hardware, driving development, and assembly the requests of an progressively associated world.