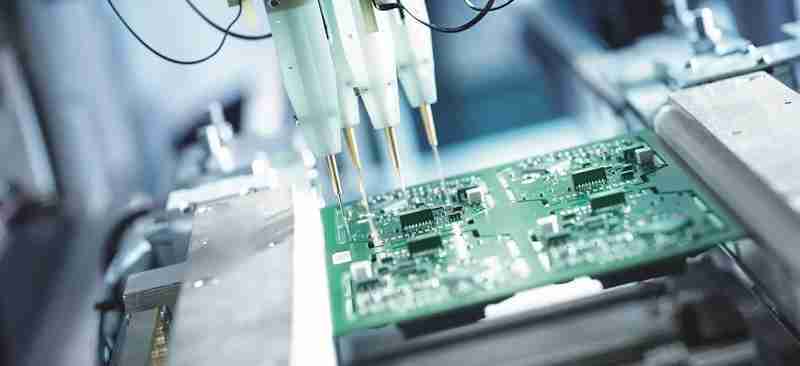

The Printed Circuit Board (PCB) is the spine of for all intents and purposes all cutting edge electronic gadgets. From mobile phones and computers to restorative hardware and automotive frameworks, PCBs play a significant part in guaranteeing the usefulness and unwavering quality of these items. As a result, PCB board fabrication is a profoundly specialized prepare that requests a fastidious approach. PCB board manufacturers take a few basic steps to guarantee the quality, exactness, and unwavering quality of their items. This Content investigates the strategies utilized by PCB fabrication manufacturers to keep up tall measures in production.

Understanding PCB Fabrication: An Overview

PCB Board Fabrication alludes to the prepare of planning and fabricating a printed circuit board that interfaces and bolsters different electronic components. The manufacture handle includes a assortment of stages, counting planning the schematic, making the board format, carving the copper layers, penetrating gaps, and applying defensive coatings. A PCB Board Manufacturer must adjust different variables, such as fabric quality, plan complexity, and generation proficiency, to accomplish the ideal quality for the conclusion product.

Due to the expanding request for littler, more complex, and dependable electronic gadgets, the PCB manufacture handle has ended up progressively modern. Present day PCB board manufacturers utilize progressed innovations and hardware to meet these requests, guaranteeing accuracy and solidness in each organize of production.

Key Steps to Guarantee Quality and Precision

1. Material Choice and Quality Control

The establishment of quality PCB manufacture lies in selecting the right materials. The most common fabric utilized for PCB sheets is FR4, a composite fabric made from woven fibreglass and epoxy tar. In any case, other materials such as polyimide, ceramic, or PTFE may be utilized depending on the application’s particular necessities, such as higher working temperatures or electrical properties.

A PCB Fabrication Manufacturer guarantees that the crude materials meet the most elevated benchmarks by sourcing them from legitimate providers. Approaching fabric assessments are performed to confirm that the materials accommodate to industry measures and details. For case, the thickness of copper layers, the quality of covers, and the electrical properties of materials are all carefully checked some time recently they are utilized in production.

2. Design Validation

Before any physical creation takes put, the plan stage plays a pivotal part in guaranteeing that the PCB will work as aiming. PCB creators utilize computer-aided design (CAD) computer program to make nitty gritty formats and schematic charts. The plan is at that point subjected to thorough approval forms, such as Design Rule Checks (DRC) and Electrical Rule Checks (ERC), which guarantee that there are no issues that may influence the execution or manufacturability of the PCB.

Once the plan is approved, manufacturers utilize specialized program to produce the fundamental information for manufacture, counting layer stack-up data, penetrate records, and other basic enlightening for the generation handle. This step guarantees that there are no plan blemishes that might lead to abandons in the last product.

3. Precision in PCB Board Fabrication

The exactness included in PCB board manufacture is basic to guarantee the usefulness and unwavering quality of the last item. One of the key variables in accomplishing tall accuracy is the precision of the PCB board manufacturer’s gear. Here are a few of the strategies utilized to accomplish precision:

• Laser Direct Imaging (LDI): Laser Direct Imaging innovation has revolutionized the way PCB sheets are made. Instep of conventional photo masks, LDI frameworks utilize high-powered lasers to straightforwardly type in circuit designs onto the PCB’s surface. This strategy permits for much better subtle elements and guarantees exactness in making the copper follows that interface electronic components.

• Automated Penetrating and Steering: Penetrating is an fundamental portion of PCB manufacture, as gaps are required for mounting electronic components or making vias (inter-layer associations). Robotized penetrating frameworks with CNC (Computer Numerical Control) capabilities are utilized to guarantee the exactness and exactness of gap arrangement. These frameworks are competent of penetrating gaps as little as a few microns, guaranteeing that the PCB will meet exacting plan requirements.

• Layer Enlistment and Arrangement: In multi-layer PCBs, it is basic to adjust and enroll the layers accurately to guarantee legitimate electrical network between them. Progressed arrangement frameworks utilize optical sensors to adjust each layer with millimeter exactness. Misalignment amid this step can lead to shorts, flag misfortune, or indeed total disappointment of the PCB.

4. Inspection and Testing Amid Fabrication

Quality control does not conclusion once the PCB is manufactured; ceaseless review and testing are imperative to guarantee that the board meets all execution details. The taking after testing strategies are utilized by PCB manufacture manufacturers:

• Automated Optical Inspection (AOI): AOI is a non-destructive testing method that employments high-resolution cameras to review the PCB for visual abandons, such as open circuits, brief circuits, or misalignment. AOI frameworks can rapidly check huge bunches of PCBs, giving high-throughput review with amazing precision.

• Flying Probe Testing (FPT): Flying test testing is utilized for checking the electrical usefulness of the PCB. This method includes utilizing different test tests that move over the PCB to degree the electrical keenness of the follows and components. It guarantees that there are no covered up surrenders that might influence the execution of the board.

• X-Ray Inspection: In a few cases, especially in high-end PCBs with complex plans, X-Ray Inspection is utilized to identify covered up absconds such as voids or misaligned inside layers. This strategy is basic for guaranteeing the quality of high-density interconnect (HDI) sheets, which regularly utilize fine-pitch components and progressed steering techniques.

5. Post-Fabrication Quality Checks

Once the PCB is created and tried, a arrangement of last assessments and checks are conducted to guarantee that it meets all client details. These include:

• Visual Assessment: A careful visual review is performed to check for any corrective absconds, such as scratches, discoloration, or blemishes in the patch cover. This step guarantees that the PCB meets stylish and utilitarian standards.

• Functional Testing: In numerous cases, PCBs are subjected to utilitarian testing, where they are collected with components and tried for by and large execution. This makes a difference confirm that the PCB is competent of dealing with the electrical loads, frequencies, and other operational parameters it will encounter in real-world applications.

• Environmental Testing: In certain businesses, such as aviation and car, PCBs must be able to withstand extraordinary natural conditions. Natural testing, counting warm cycling, mugginess, and vibration tests, is carried out to guarantee that the PCB will perform dependably in unforgiving environments.

6. Certifications and Compliance

Another basic angle of quality control in PCB board manufacture is adherence to industry guidelines and certifications. Numerous PCB manufacturers are certified beneath worldwide benchmarks such as ISO 9001, which guarantees that they follow to thorough quality administration frameworks. Furthermore, particular certifications such as UL (Underwriters Laboratories) certification, RoHS (Restriction of Hazardous Substances), and IPC guidelines (Institute for Printed Circuits) are required to guarantee that the PCBs meet security, natural, and execution criteria.

Conclusion

Ensuring the quality and exactness of PCB board fabrication is a complex and profoundly point by point handle. A trustworthy PCB board Manufacturer utilizes a wide run of strategies to guarantee that each board meets the most noteworthy measures of usefulness, solidness, and unwavering quality. From selecting the right materials and utilizing state-of-the-art fabricating innovations to conducting intensive testing and reviews, PCB fabrication manufacturers take off no room for blunder. By following to exacting quality control measures and industry certifications, they convey items that control the hardware that shape our world nowadays. Whether for customer gadgets, restorative gadgets, or aviation applications, the accuracy of PCB board manufacturers guarantees that these imperative components proceed to work consistently in an ever-evolving innovative scene.