SMT (Surface Mount Technology) plays a vital role in modern electronic manufacturing.

The first SMT production is a crucial link to ensure the smooth progress of the entire production process.

The process verifies the rationality of the design drawings or process requirements and provides a significant demonstration for subsequent production.

The following will discuss the steps and precautions for SMT first-piece production.

Preparation before production

Before starting the first-piece SMT production, detailed preparation work is required:

1.Clarify production requirements

First, clarify the production requirements of the first-piece SMT, including design drawings, process requirements, quality standards, etc.

This step ensures that the entire production process has clear goals and direction.

2.Preparation of Materials and Equipment

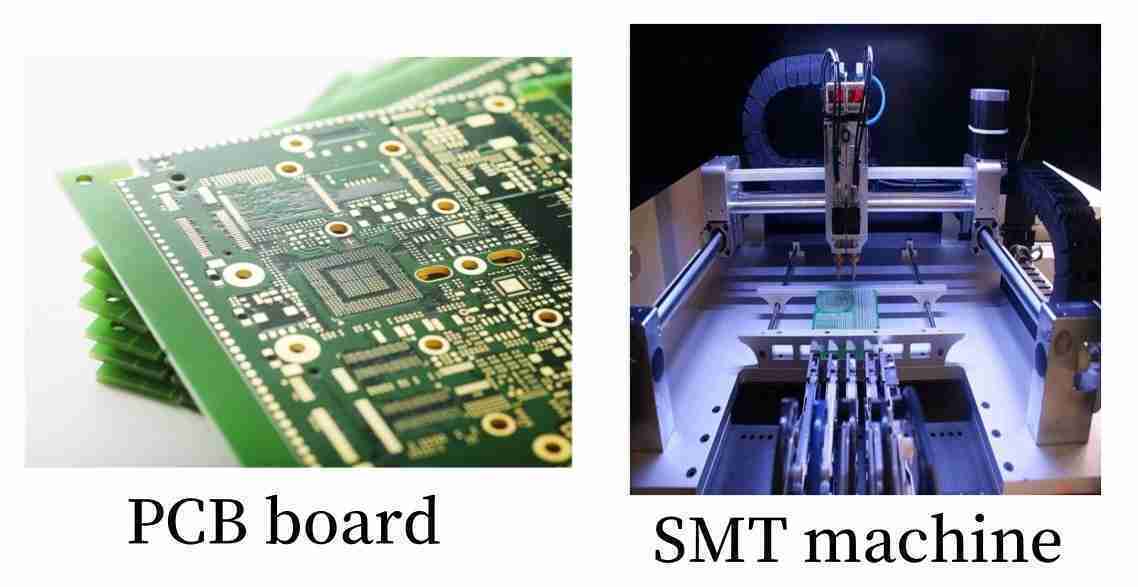

Prepare the required SMT components, PCB boards, SMT equipment, and tools.

It ensures all materials meet quality standards and that equipment is in good condition.

3.production staff

Select experienced personnel familiar with SMT technology to produce the first -piece of SMT.

Skilled craft is essential to ensure the high quality of the first-piece SMT.

Production flow

1.Made according to design requirements

According to the design drawings and process requirements, the first-piece SMT is produced according to the quality standards.

It includes accurately placing SMT components on PCB boards and ensuring that the soldering process meets standards.

2.Process control and inspection

During the production process, perform continuous process control and inspection.

It includes real-time monitoring of SMT component position, soldering quality, PCB board dimensions, etc.

If any problems are found, we should adjust and improve promptly.

3.Quality Control

Implement strict quality control to ensure that the first-piece SMT meets the quality standards.

It requires the use of technologies such as X-ray inspection to ensure the quality of welding and the accuracy of component positioning.