FCT (Functional Circuit Testing) and ICT circuit test (In-Circuit Testing) are two commonly used testing methods in circuit board manufacturing to ensure the quality and performance of printed circuit boards and electronic devices.

There are obvious differences between them in test purpose, test methods, and applicable scenarios. This article will explore the differences between these two test methods in detail.

ICT(In-Circuit Testing)

ICT test is an early electronic testing method mainly used to detect connection and soldering errors during PCB assembly. The following are the main features and functions of ICT:

1) Used in the PCB manufacturing process

ICT is often used in the early stages of PCB assembly to detect the component’s correct mounting and connection. It is usually after soldering but before final assembly.

2) Point-to-point testing

ICT uses probes and test fixtures to perform point-to-point tests on various connection points on the PCB. These test points are usually soldering points or connection points on the PCB.

3) Detect connection problems

The main goal of ICT circuit test is to detect connection problems such as shorts, opens, wrong polarity, etc. It can detect problems where components are not inserted correctly or soldered unsecurely.

4) High-precision testing

ICT typically provides highly accurate test results and can detect little connection problems. So, it become a powerful tool for discovering circuit board fabrication defects.

5) Not suitable for functional testing

ICT is primarily used for connectivity testing. Therefore, it is not suitable for complete functional testing. It cannot test the performance or functionality of a component.

6) High cost

ICT has higher test fixture and equipment costs and longer test times. Therefore, it is often used in demanding production environments, such as connection quality.

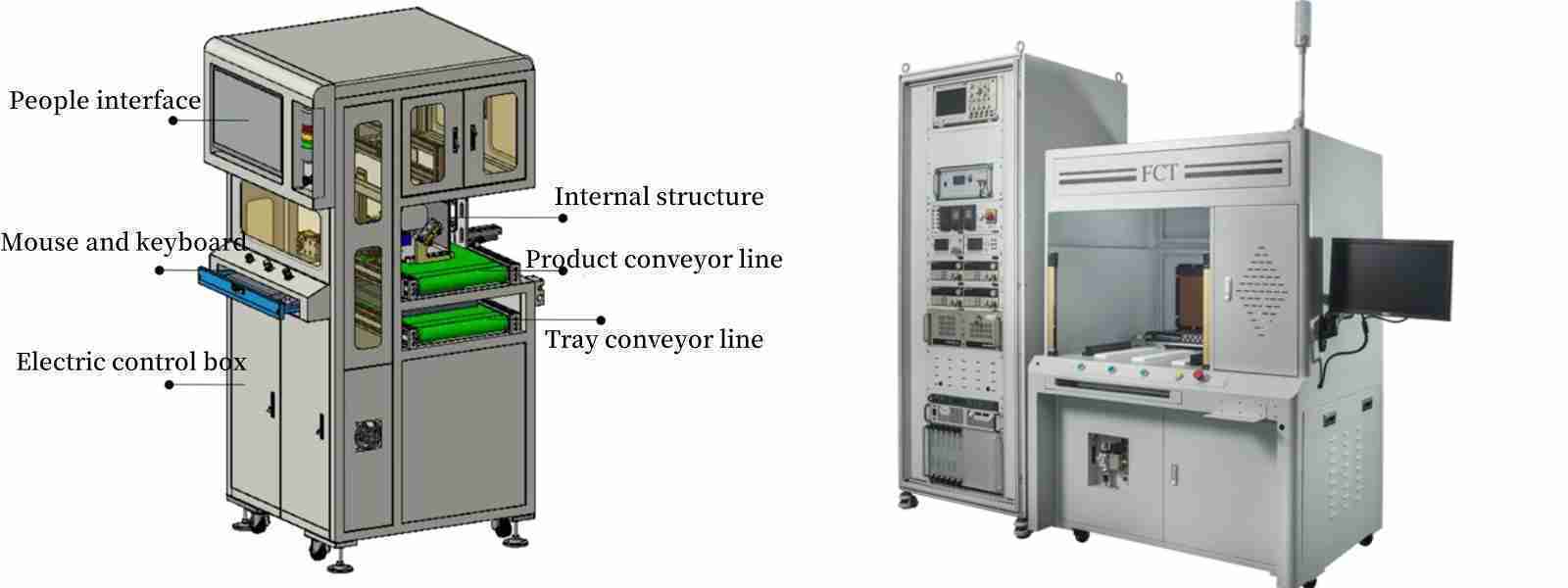

FCT functional circuit test

FCT is a more advanced test method. It is used after ICT to test the functionality and performance of electronic equipment. The following are the main features and functions of FCT:

Final Assembly Testing: FCT is usually performed during the final assembly stage of PCB assembly to ensure that the functionality and performance of the entire circuit card meet specifications.

Functional testing: FCT tests the entire circuit card assembly functionality. It verifies the expected function according to the design specifications.

Connection Testing: Although the FCT primarily focuses on functional testing, it can detect connection issues, such as loose or bad cable connections.

Automated testing: FCT typically uses automated test equipment and test procedures to perform tests quickly, repeatably, and efficiently. It makes FCT suitable for high-volume PCB production environments.

Detect whole performance: FCT tests the function of individual components but also the performance of the entire system. It includes testing the device response time, power consumption, communication protocol, and other aspects.

More comprehensive testing: Compared to ICT, FCT provides a more comprehensive inspection because it covers the overall equipment performance and functionality.

Inspection cost: Although FCT provides a more comprehensive test, it is generally more expensive than ICT.

summary

After summarizing the above differences, we know that ICT and FCT play different roles in printed circuit board manufacturing.

ICT is mainly used to detect connection problems and welding quality, while FCT is used to test the functionality and performance of the entire device.

Therefore, they are often used at different stages of production to ensure the high quality and reliability of electronic products before they are delivered to the end user. Choosing which test method to use usually depends on the product type, production requirements, and test objectives.

In actual circuit board production, we usually use these two testing methods together to ensure the high quality and performance of the product.