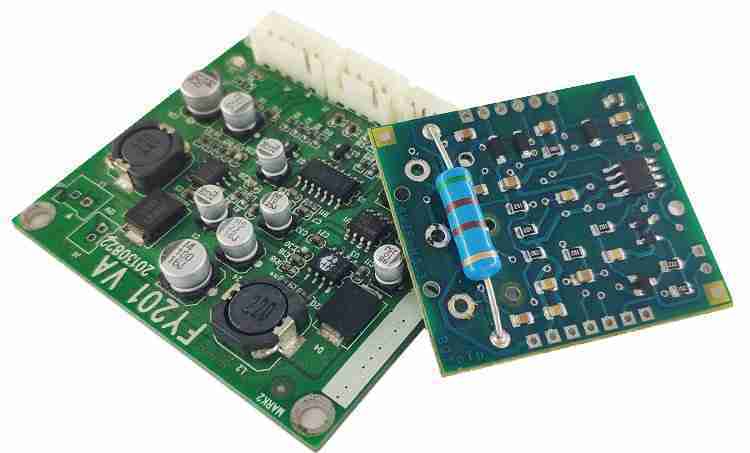

After the PCB layout is completed, we require to inspect all its project functions. Similar to we end up the test paper ourselves, we should do a straightforward evaluation and inspect all its issues again to make certain that we will not make big blunders because of oversight. The complying with Premium quality PCB PCBA handling producer will certainly explain the appropriate expertise of how to eliminate the short circuits fault of PCBA processing.

1. Open up the PCB style drawing on the computer system, illuminate the short-circuited network, and see where it is closest and simplest to link. Pay special attention to the short circuit inside the IC., If it is hand-operated welding, create great routines.

2. By hand aesthetically examine the PCB once prior to welding, and utilize a multimeter to inspect whether the essential circuit shorted, particularly the power supply and ground.

3. Each time a chip is welded, we should use a multimeter to check whether the power supply and ground are short-circuited.

4. When soldering in PCBA manufacturing, do not swing the blowpipe randomly. If you inadvertently go down solder onto the chip’s pins, it will certainly be tough to spot and find the short circuit, particularly surface area place parts. Take a board to reduce the line (particularly be suitable for single/double-layer boards). After reducing the line, power on each functional block independently and gradually remove them.

5. Make use of a short circuit positioning and analysis tool.

6. There are BGA contribute PCBA patch handling. There are BGA chips in PCBA spot handling. Given that all solder joints are covered by the chip and can not be seen, and it is a multi-layer board (more than 4 layers), it is best to separate the power supply of each chip throughout design and connect them with magnetic grains or zero ohm favorable electrodes. This way, when the power supply and ground are short-circuited, separating the magnetic bead detection makes it very easy to identify a particular chip. Due to the difficulty of BGA welding, if you do hands-on welding manually, you will short-circuit the two nearby power and ground solder balls if you are not cautious.

7. Take care when welding small-sized surface area mount capacitors, specifically power filter capacitors (103 or 104). There are a lot of them, which can easily trigger a short circuit between the power supply and the ground.