PCB prototype production is a significant stage before mass production and plays a testing role. Before mass production, the product must be tested to ensure that the product has no design defects or functional disorders. A tiny mistake will cause the PCB board to become an expensive and useless waste board, so before carrying out complex designs, designers usually order PCB prototypes to test redesigns or individual functions. That enables them to identify elements that need to be corrected in the early process. The earlier problems are discovered, the lower the manufacturing cost.

What is a PCB Prototype?

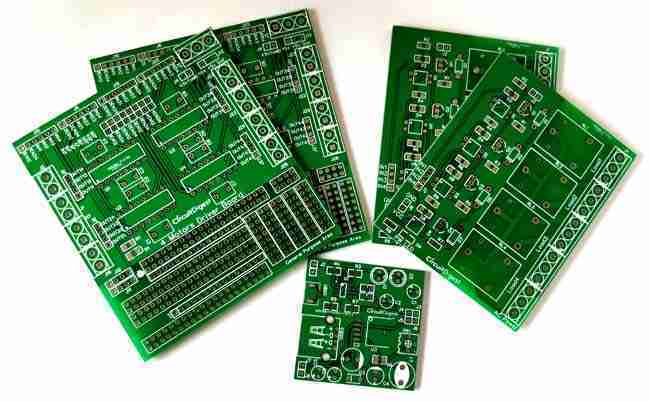

PCB prototype is also called a printed circuit board or prototype circuit board. PCB prototype is usually a simpler and more basic version of the finished printed circuit board. It is an authentic PCB sample development. It must be a test version to ensure the accuracy, high quality, and full functionality of the final circuit. At this stage, the prototype circuit board assembly should be as close as possible to the design, function, and number of components loaded as the finished product. After PCB prototype testing is accomplished, it can be mass-produced.

What is the purpose of the PCB Prototype?

As we all know, PCB Prototyping is a significant link to ensuring PCB quality. The purpose of the prototype is not only to test the quality of the finished product but also to reduce defects in the PCB production process. The purposes of PCB proofing are as follows:

What is a PCB Prototype?

Circuit design is a very complex process, especially in the design of multi-layer boards such as 10-layer and 12-layer boards. Whether the circuit design is reasonable and whether the circuit board manufacturing is feasible must be known through PCB prototype testing.

Reduce production defects

PCB manufacturing is complex, and every process must be correct. After the PCB proofing, it will be fully tested by professional technicians. The test content includes the lamination, cleanliness, electrical integrity, circuit impedance, and other aspects of the circuit board. Only after confirming that there are no faults can the PCB be mass-produced.

Judging the Strength of PCB Manufacturers

The quality of printed circuit boards determines whether electronic products can operate normally. Through prototype PCB proofing, we can further understand the processing and assembly capabilities of the PCB manufacturers, especially those that we have not cooperated with before. Each manufacturer has its advantages in technology, but there are differences in processing capabilities. At this stage, you can choose a strong PCB manufacturer to lay the foundation for the mass production of PCBs in the future.

PCB Prototype Advantages

Whether it is the prototype PCB design stage or the mass production stage, it is beneficial to use prototype PCB. There are several benefits to using PCB prototypes :

• Reflect standard PCB performance

• Early detection of defects

• Fast turnaround time

• Testing parts individually

• Reduce project development costs

• Improve your product

When to do the PCB prototype?

PCB prototyping is important when producing PCBs on a large scale, but not every PCB produced in batches needs PCB proofing. So, when do we need and when do we not need PCB prototype services?

• When you have a new PCB design project ready to implement, you need prototype PCB manufacturing

• If your circuit board design is already in mass production, there is no need for PCB prototyping.

• If your PCB design is changed or upgraded, you need to customize the PCB prototype board

At Circuit Card Assembly, we provide you with one-stop services for PCB prototyping and mass production of PCBs. You don’t need to cooperate with multiple PCB manufacturers, making the entire process more efficient and economical and achieving a win-win situation.

Why choose Circuit Card Assembly?

Our PCB factory is located in Shenzhen, China. We have rich experience, wide business scope, and a complete industrial chain. We are not limited to PCB prototype supply and production, we also provide prototype PCB assembly services.Our goal is to be the best prototype PCB manufacturer in the country.

Rapid PCB prototyping services

We have a professional technical team and fully automated production equipment. We have invested heavily in introducing advanced foreign PCB production equipment, such as Berkeley laminators, Hitachi drills, Japanese screen automatic exposure machines, LDI, AOI, etc., and they are on call for production 24 hours a day. We can complete the production tasks within the specified time.

Low cost

At Circuit Card Assembly, we do not have a minimum order quantity. No matter how much or how little you order, we will deliver the products to you on time with guaranteed quality and quantity.