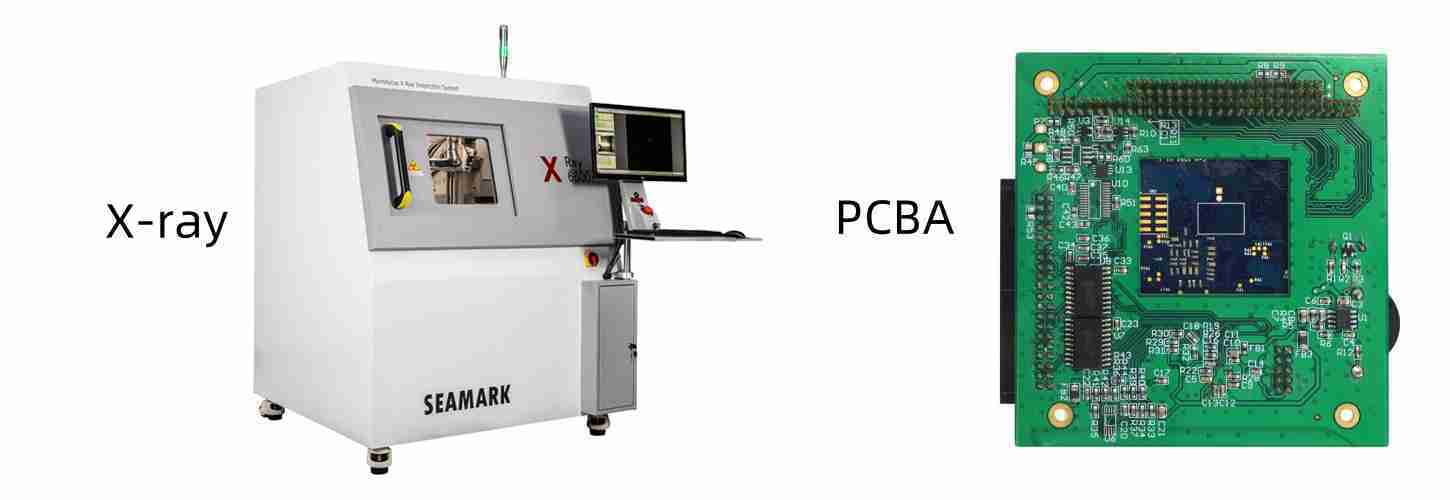

PCBA process X-ray inspection is a non-destructive testing method used to detect the soldering points, packaging, and wiring of PCBA.

It has the following advantages.

1)It can detect defects that traditional methods cannot detect.

PCBA X-ray inspection can detect defects that traditional methods cannot detect, including the following categories:

• Welding defects

Soldering defects are common in PCB assembly, including solder joint voids and cracks, solder bridging, short circuits, open circuits, etc.

• Packaging defects

Package defects refer to defects in packaged components, including package deformation, package cracks, package open circuits, etc.

• Wiring defects

Wiring defects refer to defects in wiring, including wire breakage, wire short circuit, wire open circuit, etc.

These defects may cause the PCBA to decline in performance or fail. X-ray testing can detect these defects.

2) Fast speed and high efficiency

PCBA process X-ray inspection can be completed quickly, generally, only a few seconds to complete the inspection of a PCBA.

It can improve circuit board manufacturing efficiency and shorten the time to market.

The X-ray inspection speed in the PCBA (Printed Circuit Board Assembly) process is fast, mainly due to the following reasons:

High-resolution images: X-rays can produce high-resolution images, which clearly show details without physical contact.

Instant imaging: X-ray inspection systems can generate images immediately without waiting or other processing steps.

Automation: X-rays can be integrated into the production line and automatically transmit images for inspection without manual intervention.

Multi-angle inspection: Moving the handle allows the X-ray to inspect the PCBA from different angles, fully inspecting without moving the PCBA.

3) Non-destructive testing, no damage to PCBA

PCBA process X-ray inspection is a non-destructive testing method that can batch testing and improve testing efficiency.

It is mainly reflected in the following aspects:

• X-ray Penetration

X-rays are a type of electromagnetic wave with strong penetrating power that can penetrate the copper foil, substrate, and solder of PCBA.

Therefore, X-ray inspection can inspect the PCBA’s inside without damaging the surface of the PCBA.

• Energy of X-rays

The energy of the X-rays can be adjusted as needed.

For PCBA inspection, low-energy X-rays are usually used to reduce damage to the PCBA.

• Protection measures for X-ray inspection equipment

X-ray inspection device is equipped with protective devices to prevent X-rays from harming the human body and PCBA.

Application scenarios of X-ray inspection

PCBA process X-ray inspection can be used in various stages of PCBA production, including:

1) Pre-test before reflow

Pre-inspection before reflow can detect welding defects to prevent them from being enlarged during reflow.

2) Final inspection after reflow

Final inspection after reflow can ensure soldering quality and PCBA performance and reliability.

3) Full monitoring during PCBA production

Full monitoring during the PCBA production process can detect problems promptly and take measures to correct them, thereby improving product quality.

In conclusion

PCBA process X-ray inspection is an important quality control method in the PCBA manufacturing process and has the advantage of non-destructive testing.

It can help PCB manufacturers ensure product quality and reliability and improve product yield and market competitiveness.