Printed Circuit Board Applications and Types

Printed circuit board is present in mostly all digital gadgets we see and make use of daily. They are in charge of making numerous gadgets we utilize everyday look smaller while containing a lot more innovation. Its applications include:

• Televisions and radios

• Computer systems

• Alarm systems

• Coffee equipments

• Cleaning machines

• Game consoles

• Smart phone

• Stoves

Other application locations include army, clinical, and commercial elements (bikes, automobiles, airplanes, and so on).

In most digital products, a printed circuit board (PCB) is made use of as a base to support circuitry and its socket elements installed on a surface.

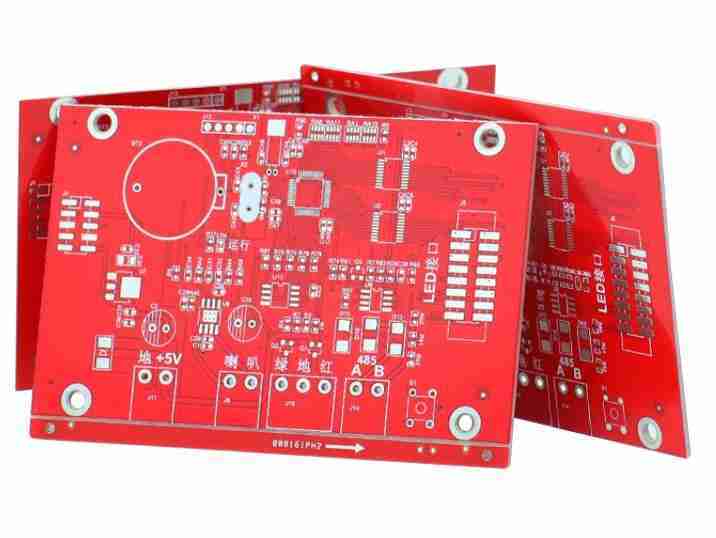

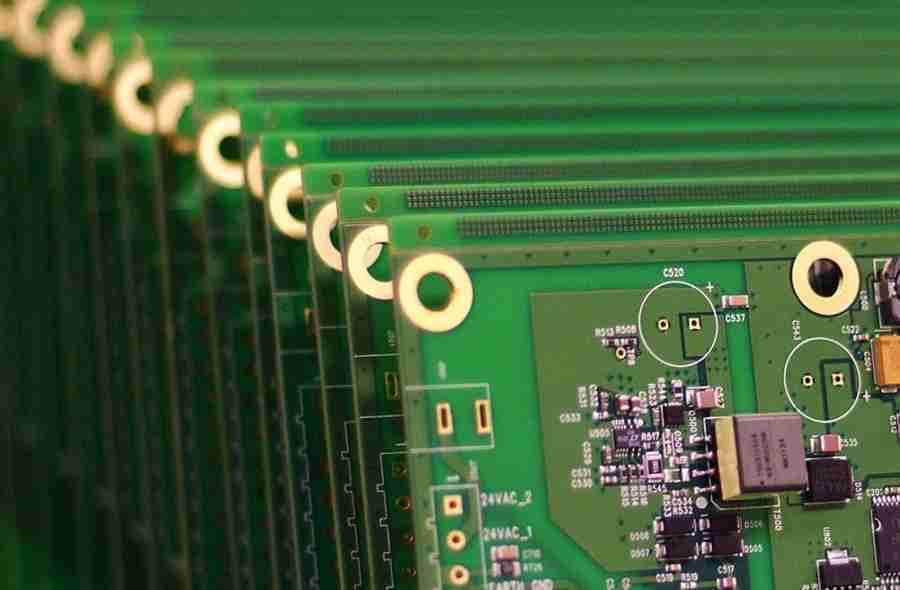

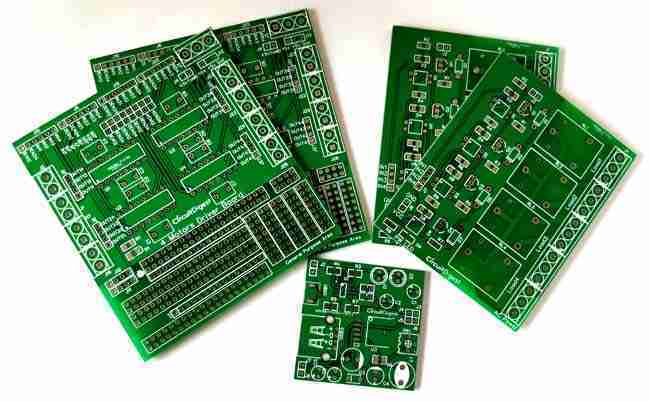

PCBs for straightforward electronic gadgets are single-layer. Facility electronic printed circuit board, such as motherboards and digital graphics cards, can have up to twelve layers. PCBs are generally eco-friendly, but can also be customized to any type of shade.

In applications that call for fine conductive circuitry, such as computer systems, PCBs are developed using a photolithography procedure, which is a scaled-up variation of just how connections are produced in cpus.

Review of PCB Production Refine

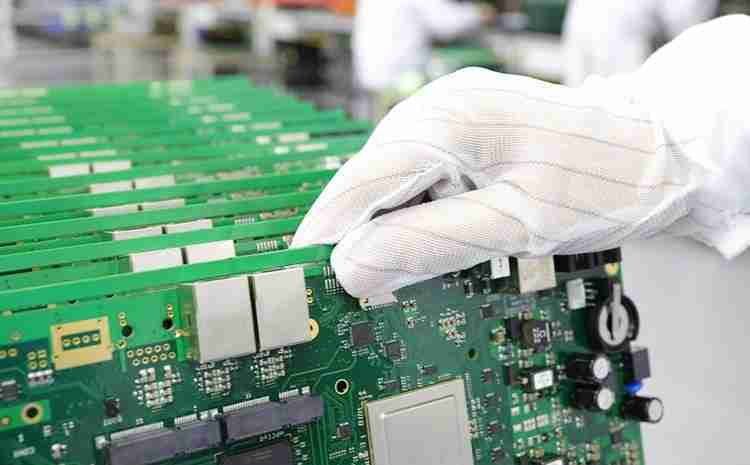

It is vital to understand the difference between PCB production and its setting up procedure. PCB manufacturing consists of PCB design and prototyping processes, while PCB assembly includes mounting elements on printed circuit board.

Unlike normal cords, PCBs normally attach electrical components with copper tracks. Pierced holes in the board are used to protect the electric components. They are soldered in place, and the copper tracks attach them to develop a circuit. The PCB and the elements attach with each other are called a PCB assembly or PCBA (printed circuit broad assembly). Without this assembly process, the PCB is a board without feature, and its value is self-evident.

Now, we will take a much deeper check out PCB production.

Machines usually utilize solder to secure the digital devices to the ended up suitable PCB. The PCB is baked in an industrial microwave oven to melt the solder that connects the elements. Most PCBs are made up of fiberglass or glass-reinforced polymers with copper traces.

The 3 primary processes of PCB production are PCB design, component sourcing, and PCB assembly. Whether the PCB design and production is for small or big batches of PCBs, design for testability (DFT) and design for manufacturability (DFM) are essential operations to ensure the maximum return within the project cost. Unlike manufacturing, the assembly of a specific PCB may vary depending on your preference or application.

Latest Blog

Table of Content

Contcat Us

Phone: +86-18123905375

Email: sales@circuitcardassembly.com

Skype: ali_youte

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Afrikaans

Afrikaans Shqip

Shqip አማርኛ

አማርኛ العربية

العربية Հայերեն

Հայերեն Azərbaycan dili

Azərbaycan dili Euskara

Euskara Беларуская мова

Беларуская мова বাংলা

বাংলা Bosanski

Bosanski Български

Български Català

Català Cebuano

Cebuano Chichewa

Chichewa 简体中文

简体中文 繁體中文

繁體中文 Corsu

Corsu Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Esperanto

Esperanto Eesti

Eesti Filipino

Filipino Suomi

Suomi Français

Français Frysk

Frysk Galego

Galego ქართული

ქართული Deutsch

Deutsch Ελληνικά

Ελληνικά ગુજરાતી

ગુજરાતી Kreyol ayisyen

Kreyol ayisyen Harshen Hausa

Harshen Hausa Ōlelo Hawaiʻi

Ōlelo Hawaiʻi עִבְרִית

עִבְרִית हिन्दी

हिन्दी Hmong

Hmong Magyar

Magyar Íslenska

Íslenska Igbo

Igbo Bahasa Indonesia

Bahasa Indonesia Gaeilge

Gaeilge Italiano

Italiano 日本語

日本語 Basa Jawa

Basa Jawa ಕನ್ನಡ

ಕನ್ನಡ Қазақ тілі

Қазақ тілі ភាសាខ្មែរ

ភាសាខ្មែរ 한국어

한국어 كوردی

كوردی Кыргызча

Кыргызча ພາສາລາວ

ພາສາລາວ Latin

Latin Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba Lëtzebuergesch

Lëtzebuergesch Македонски јазик

Македонски јазик Malagasy

Malagasy Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം Maltese

Maltese Te Reo Māori

Te Reo Māori मराठी

मराठी Монгол

Монгол ဗမာစာ

ဗမာစာ नेपाली

नेपाली Norsk bokmål

Norsk bokmål پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português ਪੰਜਾਬੀ

ਪੰਜਾਬੀ Română

Română Русский

Русский Samoan

Samoan Gàidhlig

Gàidhlig Српски језик

Српски језик Sesotho

Sesotho Shona

Shona سنڌي

سنڌي සිංහල

සිංහල Slovenčina

Slovenčina Slovenščina

Slovenščina Afsoomaali

Afsoomaali Español

Español Basa Sunda

Basa Sunda Kiswahili

Kiswahili Svenska

Svenska Тоҷикӣ

Тоҷикӣ தமிழ்

தமிழ் తెలుగు

తెలుగు ไทย

ไทย Türkçe

Türkçe Українська

Українська اردو

اردو O‘zbekcha

O‘zbekcha Tiếng Việt

Tiếng Việt Cymraeg

Cymraeg isiXhosa

isiXhosa יידיש

יידיש Yorùbá

Yorùbá Zulu

Zulu