Surface Mount Technology (SMT): Disclosing the Insider facts of Circuit Boards and PCB Assembly

In the ever-evolving world of hardware, circuit boards shape the spine of mechanical progressions. Among the different sorts of printed circuit boards accessible nowadays, SMT circuit boards, SMT PCB boards, surface mount PCBs, and Assembled circuit boards are at the bleeding edge of cutting edge hardware. These advances have revolutionized the plan, Manufacturing, and application of electronic gadgets. This article dives profound into the subtleties of these boards, highlighting their features, applications, and advantages.

What is SMT Technology?

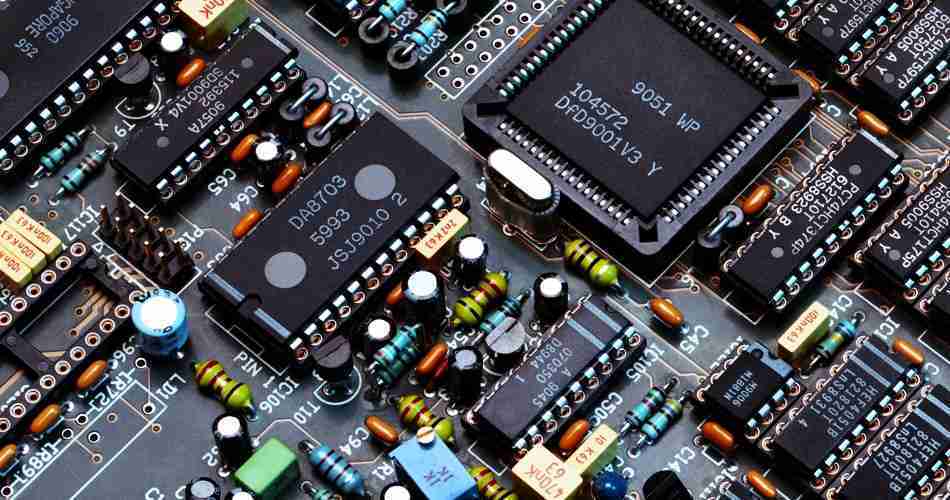

Surface Mount Technology (SMT) is a strategy employed to produce electronic circuits. Not at all like conventional through-hole Technology, SMT includes mounting components straightforwardly onto the surface of a printed circuit board (PCB). This inventive approach permits for littler, more productive, and more dependable electronic gatherings. The components utilized in SMT are alluded to as Surface Mount Devices (SMDs).

The approach of SMT has been a game-changer for businesses dependent on compact and lightweight gadgets. From keen phones to restorative hardware, SMT Technology has made it conceivable to accomplish high-performance gadgets in compact designs.

SMT Circuit Boards: An Overview

1. Definition

An SMT circuit board is a PCB outlined for face- mount factors. These boards are necessarily to the usefulness of present day electronic gadgets due to their compact plan and tall efficiency.

2. Design

The plan of SMT circuit boards centres on obliging SMDs. This includes exact formats and the utilize of specialized apparatuses like patch glue, reflow stoves, and pick-and-place machines. SMT boards regularly have fine follows and cushions planned to handle little, thickly pressed components.

3. Highlights of SMT Circuit Boards

• Compact Measure: The coordinate mounting of components dispenses with the require for boring gaps, coming about in littler boards.

• High Thickness: Components can be set on both sides of the board, expanding the circuit density.

• Improved Execution: Shorter electrical ways improve flag keenness and diminish electromagnetic interference.

• Lightweight Plan: Perfect for versatile and wearable devices.

4. Applications

SMT circuit boards are broadly utilized in businesses such as:

• Consumer Gadgets: Smartphone’s, tablets, and laptops.

• Automotive: Motor control units and progressed driver-assistance systems.

• Healthcare: Therapeutic imaging gadgets and wearable wellbeing monitors.

• Telecommunications: Arrange switches and modems.

SMT PCB Boards: A Closer Look

1. What Are SMT PCB Boards?

SMT PCB boards are a subset of SMT circuit boards that particularly allude to printed circuit boards outlined for surface-mount Assembly. They are the physical stages where electronic circuits are built, joining conductive pathways to interface electronic components.

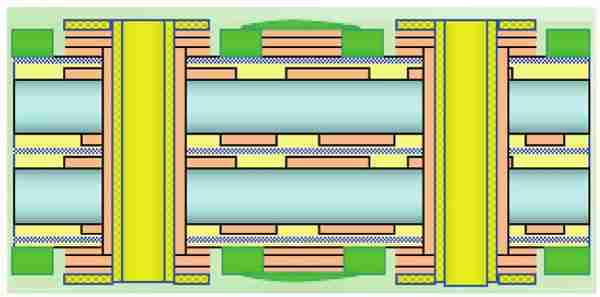

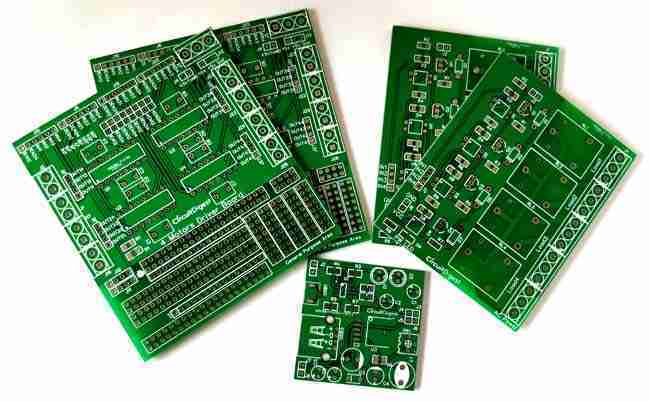

2. Sorts of SMT PCB Boards

• Single-Layer Boards: Utilized for straightforward circuits with negligible components.

• Double-Layer Boards: Give more space for complex circuits by utilizing both sides of the board.

• Multilayer Boards: Offer progressed usefulness by stacking numerous layers of circuitry.

3. Manufacturing Process

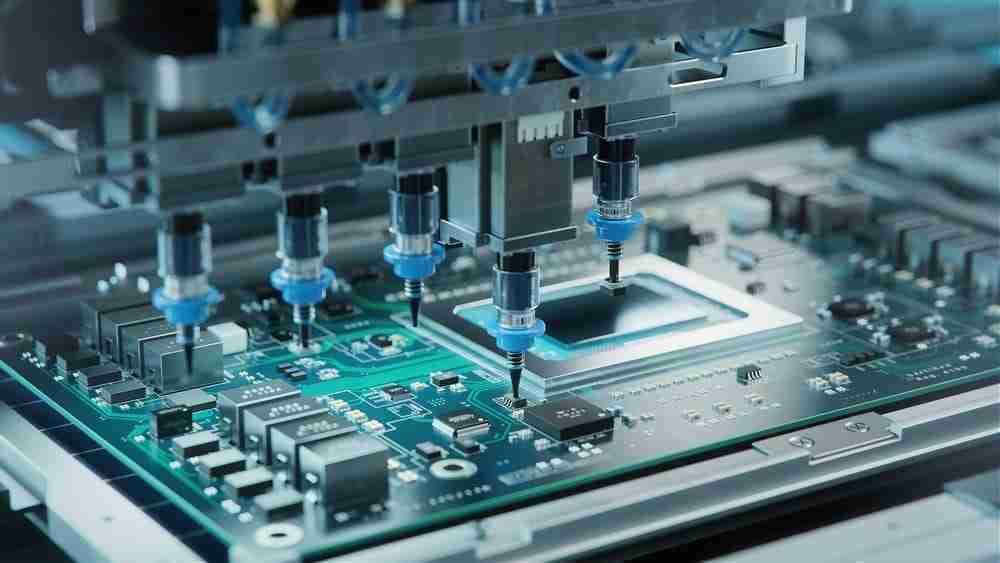

The generation of SMT PCB boards includes a few stages:

• Design: Engineers make a schematic and format utilizing PCB plan software.

• Fabrication: The board is made with conductive layers, ordinarily copper.

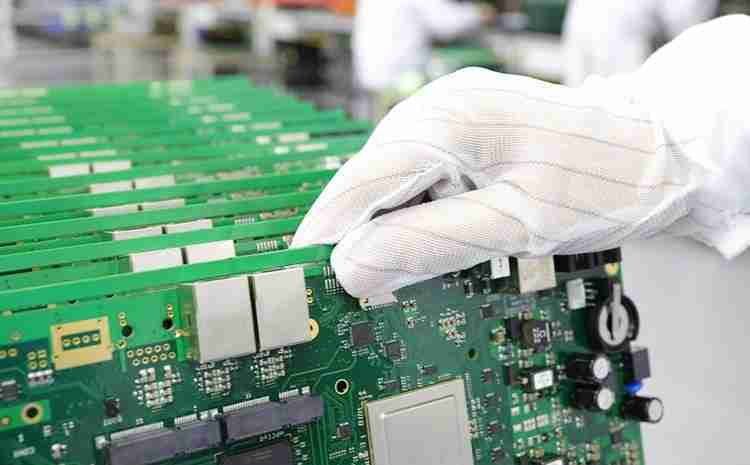

• Component Arrangement: SMDs are mounted utilizing mechanized machines.

• Soldering: Reflow fastening secures components in place.

4. Preferences of SMT PCB Boards

• Reduced fabric and Manufacturing costs.

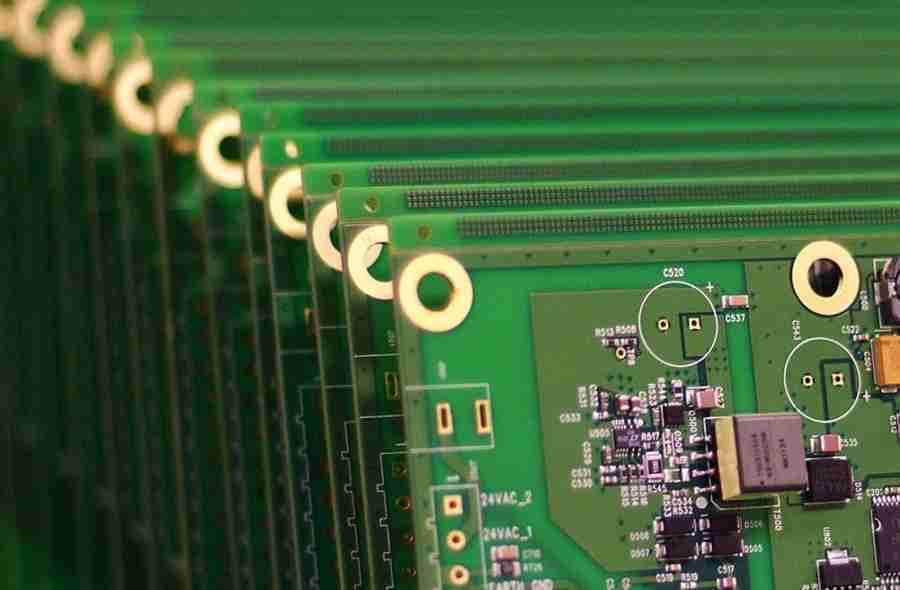

• Faster generation cycles.

• Enhanced strength and resistance to vibrations.

• Better warm administration in high-performance applications.

Surface Mount PCBs: A Profound Dive

1. Key Characteristics

Surface mount PCBs epitomize present day electronic plan. They are characterized by their utilize of SMDs, compact formats, and tall component thickness. The nonappearance of penetrated gaps gives producers more adaptability in circuit design.

2. Materials Used

The base fabric of surface mount PCBs ordinarily includes:

• FR4: A glass-reinforced epoxy laminate.

• Metal-Core PCBs: Utilized in high-power applications for viable warm dissipation.

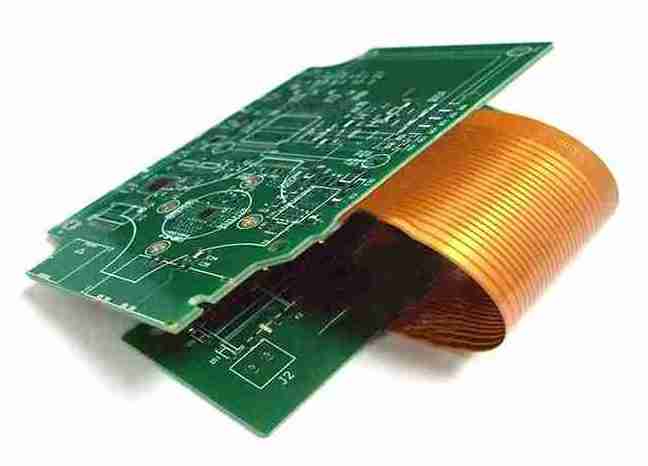

• Flexible PCBs: Reasonable for wearable and foldable devices.

3. Challenges in Surface Mount PCBs

Despite their points of interest, surface mount PCBs display certain challenges:

• Precision: Arrangement of modest components requires exceedingly precise machinery.

• Reparability: Repairs are more complex due to the compact design.

• Thermal Stretch: High-density boards can confront warm scattering issues if not planned correctly.

4. Common Applications

• Industrial Hardware: Mechanical technology and robotization systems.

• Aerospace: Route and control systems.

• Energy: Sun based inverters and control dissemination systems.

Assembled Printed Circuit Boards: The Final Product

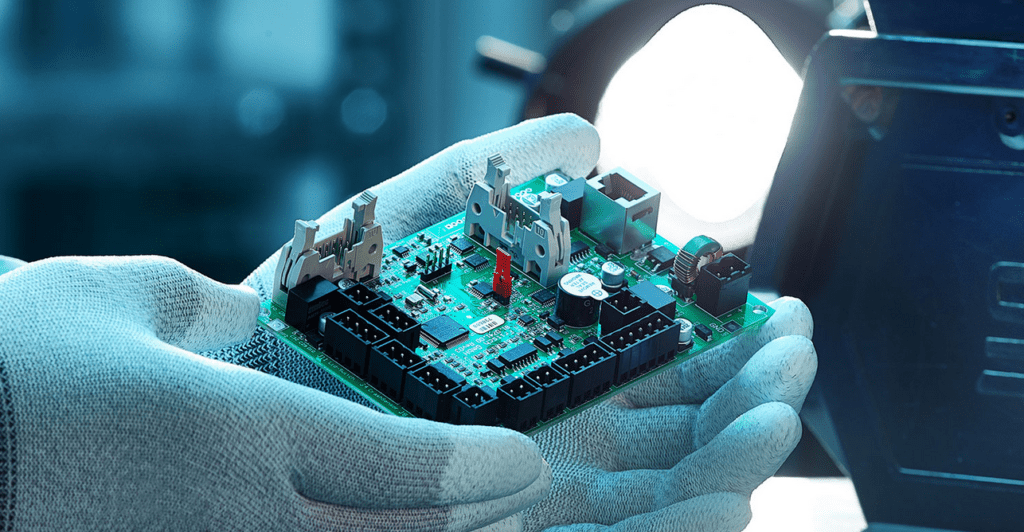

1. What are Assembled Circuit Boards?

Assembled circuit boards are completely utilitarian electronic gatherings that incorporate all vital components mounted and fastened onto a PCB. They experience thorough testing to guarantee unwavering quality and performance.

2. Sorts of Assemblies

• Prototype Congregations: Utilized for testing and improvement purposes.

• Production Gatherings: Mass-produced boards for commercial use.

• Custom Congregations: Custom-made to particular client prerequisites or applications.

3. Assembly Processes

The handle of making assembled circuit boards involves:

• Component Sourcing: Getting high-quality components.

• Mounting: Putting components on the PCB utilizing SMT or through-hole methods.

• Soldering: Securing components utilizing wave fastening or reflow soldering.

• Inspection and Testing: Guaranteeing the board meets quality benchmarks through Automated Optical Inspection (AOI) and utilitarian testing.

4. Preferences of Assembled Circuit Boards

• Ready-to-use arrangements for manufacturers.

• High unwavering quality and precision.

• Customization alternatives to suit particular needs.

Comparison: SMT Circuit Boards vs. Conventional Circuit Boards

Future of SMT and Surface Mount PCBs

The request for SMT and surface mount PCBs proceeds to rise, driven by progressions in Technology and shopper needs. Patterns forming the future include:

• Miniaturization: The thrust for littler gadgets requires indeed more compact and proficient SMT boards.

• IoT Integration: SMT PCBs are fundamentally to the developing Web of Things (IoT) ecosystem.

• Sustainability: Producers are embracing eco-friendly materials and processes.

• Advanced Materials: Advancements like adaptable and stretchable PCBs are opening unused conceivable outcomes in wearable technology.

Choosing the Right SMT PCB Manufacturer

When selecting a producer for SMT or assembled circuit boards, consider:

• Expertise: Guarantee they have encounter with your particular application.

• Equipment: Progressed apparatus guarantees exactness and quality.

• Quality Confirmation: See for certifications like ISO 9001 and RoHS compliance.

• Customization: The capacity to tailor boards to your needs.

• Cost-Effectiveness: Adjust between reasonableness and quality.

Advancements in SMT and Assembled Circuit Boards: Patterns and Technologies

The gadgets industry flourishes on persistent advancement, and SMT and amassed circuit boards stay at the centre of this advance. To superior appreciate their affect, it’s basic to investigate the headways, patterns, and future conceivable outcomes that guarantee to reshape these advances further.

Innovative Patterns in SMT Circuit Boards

1. Miniaturization of Components

The request for littler, lighter, and more effective gadgets drives advancement in component miniaturization. SMT circuit boards presently coordinated micro-scale components like 0201 and 01005 bundles, making them appropriate for applications where space imperatives are basic, such as wearables and implantable therapeutic devices.

2. Increased Circuit Density

Modern SMT PCBs include higher circuit densities to oblige complex functionalities without expanding board estimate. This includes utilizing multilayer boards with up to 16 or more layers, which guarantee the ideal utilize of surface zone whereas keeping up flag integrity.

3. Automation and Keen Manufacturing

Automation has definitely changed the gathering prepare for SMT PCBs. Shrewd industrial facilities prepared with AI-driven machines and mechanical autonomy presently handle assignments like component arrangement, fastening, and assessment with phenomenal exactness. This decreases generation blunders, improves quality, and boosts throughput.

4. Flexible and Rigid-Flex PCBs

The rise of flexible PCBs and rigid-flex PCBs, which combine unbending and adaptable areas in a single board, addresses challenges in compact and energetic applications. These boards are prevalent in aviation, car, and restorative gadgets, where space-saving and strength are paramount.

Emerging Materials and Technologies

1. Advanced Substrate Materials

Traditional FR4 materials are being supplemented or supplanted with progressed alternatives like polyimides, ceramic-based substrates, and metal-core PCBs. These materials improve warm resistance, make strides electrical execution, and empower applications in extraordinary environments.

2. 3D Printing in PCB Manufacturing

3D printing is picking up footing as a apparatus for quick prototyping of SMT circuit boards. It permits producers to create customized plans, test them rapidly, and diminish advancement cycles, making it an important instrument for innovators.

3. Embedded Components

Integrating detached and dynamic components specifically into the PCB layers diminishes Assembly complexity and upgrades board unwavering quality. This slant adjusts with the miniaturization objectives and progresses generally performance.

4. High-Speed and High-Frequency Boards

Applications such as 5G communication, radar frameworks, and progressed computing require PCBs that can handle high-speed and high-frequency signals. SMT PCBs planned with progressed materials and flag keenness optimization cater to these requesting requirements.

Challenges Confronting the SMT Industry

1. Thermal Management

As components ended up littler and more thickly stuffed, overseeing warm scattering remains a noteworthy challenge. Destitute warm administration can lead to diminished board unwavering quality and shorter life expectancies for electronic devices.

Solutions:

• Incorporating warm vias.

• Using metal-core PCBs for made strides warm conduction.

• Employing progressed warm sinks and warm interface materials.

2. Design Complexity

The expanding thickness of components and layers in SMT PCBs complicates the plan handle. Engineers must guarantee usefulness whereas following to rigid estimate and execution constraints.

Solutions:

• Advanced CAD program with recreation capabilities.

• Collaboration with experienced plan engineers.

3. Environmental Regulations

Global directions like RoHS and REACH require the utilize of eco-friendly materials and forms in PCB Manufacturing. Assembly these benchmarks can be challenging, particularly for littler manufacturers.

Solutions:

• Switching to lead-free patch and halogen-free laminates.

• Implementing squander reusing programs.

Key Contemplations for PCB Assembly Success

To accomplish a high-quality amassed circuit board, producers must consider the taking after factors:

1. Component Selection:

Choosing solid components that meet the details of the application guarantees long-term execution and durability.

2. Solder Quality:

The utilize of high-quality patch fabric minimizes absconds like cold joints and guarantees electrical continuity.

3. Testing Rigor:

Comprehensive testing at each organize of generation makes a difference distinguish and correct potential issues, guaranteeing a solid last product.

4. Supply Chain Management:

An productive supply chain guarantees opportune conveyance of components, maintaining a strategic distance from generation delays.

5. Environmental Factors:

Proper dealing with of natural conditions like stickiness and inactive power amid Assembly is pivotal for touchy components.

Conclusion: The Future is Shinning for SMT and Assembly Printed Circuit Boards

SMT circuit boards, SMT PCB boards, surface mount PCBs, and assembled circuit boards are vital in the present day gadgets scene. Their compact measure, tall proficiency, and cost-effectiveness make them the favoured choice for producers over businesses. As Technology proceeds to development, these boards will play an indeed more basic part in forming the future of hardware, clearing the way for more astute, more productive, and economical devices. The advancement of SMT circuit boards, SMT PCB boards, surface mount PCBs, and Assembled circuit boards proceeds to drive development over businesses. Their compact plans, predominant execution, and versatility to cutting edge Manufacturing forms make them vital in today’s tech-driven world.

As Technology advances, these boards will as it were develop more progressed, tending to challenges like warm dissemination, miniaturization, and natural maintainability. With headways like 3D printing, AI-driven gathering, and high-speed PCBs, the future of circuit board Technology is both energizing and limitless.

Whether you are a producer, originator, or end-user, understanding these Technologies prepares you to tackle their full potential, guaranteeing a competitive edge in a quickly advancing commercial centre. SMT and Assembled circuit boards are not fair building pieces of present day hardware; they are the establishment of tomorrow’s innovative wonders.

Latest Blog

Table of Content

Contcat Us

Phone: +86-18123905375

Email: sales@circuitcardassembly.com

Skype: ali_youte

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Afrikaans

Afrikaans Shqip

Shqip አማርኛ

አማርኛ العربية

العربية Հայերեն

Հայերեն Azərbaycan dili

Azərbaycan dili Euskara

Euskara Беларуская мова

Беларуская мова বাংলা

বাংলা Bosanski

Bosanski Български

Български Català

Català Cebuano

Cebuano Chichewa

Chichewa 简体中文

简体中文 繁體中文

繁體中文 Corsu

Corsu Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Esperanto

Esperanto Eesti

Eesti Filipino

Filipino Suomi

Suomi Français

Français Frysk

Frysk Galego

Galego ქართული

ქართული Deutsch

Deutsch Ελληνικά

Ελληνικά ગુજરાતી

ગુજરાતી Kreyol ayisyen

Kreyol ayisyen Harshen Hausa

Harshen Hausa Ōlelo Hawaiʻi

Ōlelo Hawaiʻi עִבְרִית

עִבְרִית हिन्दी

हिन्दी Hmong

Hmong Magyar

Magyar Íslenska

Íslenska Igbo

Igbo Bahasa Indonesia

Bahasa Indonesia Gaeilge

Gaeilge Italiano

Italiano 日本語

日本語 Basa Jawa

Basa Jawa ಕನ್ನಡ

ಕನ್ನಡ Қазақ тілі

Қазақ тілі ភាសាខ្មែរ

ភាសាខ្មែរ 한국어

한국어 كوردی

كوردی Кыргызча

Кыргызча ພາສາລາວ

ພາສາລາວ Latin

Latin Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba Lëtzebuergesch

Lëtzebuergesch Македонски јазик

Македонски јазик Malagasy

Malagasy Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം Maltese

Maltese Te Reo Māori

Te Reo Māori मराठी

मराठी Монгол

Монгол ဗမာစာ

ဗမာစာ नेपाली

नेपाली Norsk bokmål

Norsk bokmål پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português ਪੰਜਾਬੀ

ਪੰਜਾਬੀ Română

Română Русский

Русский Samoan

Samoan Gàidhlig

Gàidhlig Српски језик

Српски језик Sesotho

Sesotho Shona

Shona سنڌي

سنڌي සිංහල

සිංහල Slovenčina

Slovenčina Slovenščina

Slovenščina Afsoomaali

Afsoomaali Español

Español Basa Sunda

Basa Sunda Kiswahili

Kiswahili Svenska

Svenska Тоҷикӣ

Тоҷикӣ தமிழ்

தமிழ் తెలుగు

తెలుగు ไทย

ไทย Türkçe

Türkçe Українська

Українська اردو

اردو O‘zbekcha

O‘zbekcha Tiếng Việt

Tiếng Việt Cymraeg

Cymraeg isiXhosa

isiXhosa יידיש

יידיש Yorùbá

Yorùbá Zulu

Zulu