surface mount technology

SMT technology is one of the important technologies in circuitcardassembly. It has become an indispensable part of modern electronic manufacturing.

It has a great effect on the design and manufacture of electronic equipment, leading to revolutionary changes in electronic manufacturing.

The significant difference between SMT and traditional through-hole technology is that SMT adopts an advanced method.

Electronic components are mounted directly on the printed circuit board’s (PCB) surface instead of inserting into the PCB through holes.

This innovative approach allows more efficient, compact, and feature-rich electronics manufacturing.

Compared with traditional through-hole technology, SMT technology brings many advantages.

First, it improves the layout density of the circuit board, allowing more electronic components to be arranged in a limited space, thereby reducing the overall volume of the electronic device.

Secondly, the automated production process of SMT technology improves manufacturing efficiency, reduces production costs, and makes electronic products more competitive.

In addition, SMT can achieve higher quality soldering and more reliable connections, further improving the stability and reliability of electronic products.

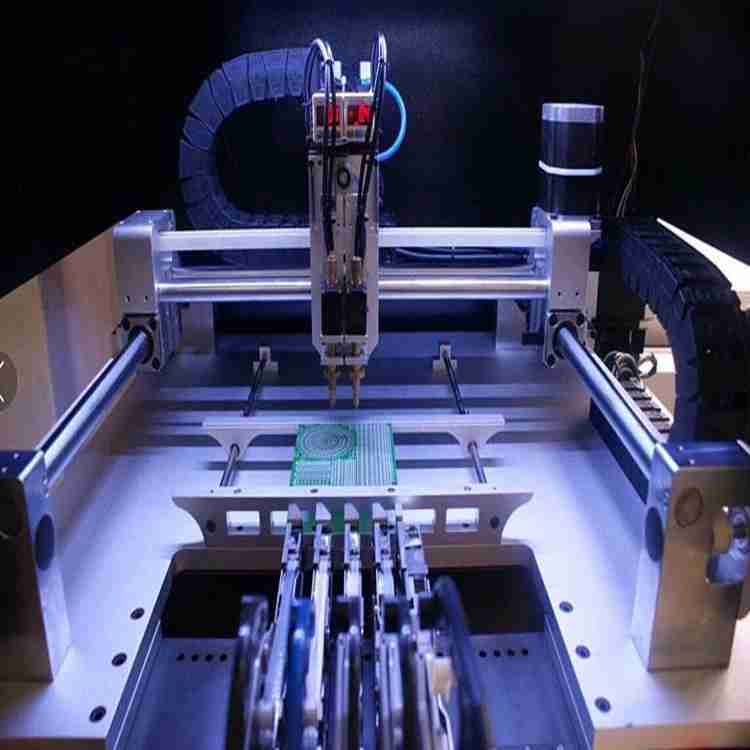

In the implementation process of SMT, a surface mount machine is a key automation equipment.

Surface mount machines can quickly and accurately mount components on PCBs through precise mechanical systems and advanced control technology.

This automated assembly process not only improves production efficiency but also reduces the error rate of manual operation and ensures product quality.

Surface Mount Devices

Surface mount devices play a crucial role in the field of electronics manufacturing.

Because unique design and performance advantages, it is an indispensable part of modern electronic products.

These devices are typically smaller and thinner than traditional plug-in components. However, they have a higher level of integration and superior high-frequency characteristics, providing flexibility and innovation in the design and performance of electronic devices.

Chip components are one of the vital categories of surface mount devices.

For example, components such as surface mount resistors and capacitors play a critical role in electronic circuits. They are designed to be small and exquisite, meeting the compact design’s need while maintaining efficient electrical performance.

It enables electronic products to achieve more functions within a limited space, improving overall performance.

In addition to chip components, surface mount devices include diodes, transistors, and integrated circuits.

These components undertake various tasks in electronic devices, from controlling current to performing complex computing functions.

Its miniaturization and lightness make electronic products more portable, meeting the demands of modern society for portability and high performance.

Compared with traditional plug-in components, surface mount devices improve the PCB board’s layout density and reduce the size of the overall equipment.

It brings greater freedom in the design of electronic devices, making innovative and personalized designs possible.

At the same time, the automated production process using surface mount technology can improve production efficiency, reduce manufacturing costs, and make electronic products more competitive.

In the development of the electronics industry, the continuous innovation and progress of surface mount devices have promoted the performance improvement and diversification of electronic products.

Its application areas cover multiple industries, such as consumer electronics, communications, and medical care, providing strong support for the various equipment’s design and manufacturing.

Overall, the miniaturization, lightweight, and high-performance characteristics of surface mount devices will continue to lead the development trend of electronic technology and lay a solid foundation for future innovation.

The introduction of SMT technology has greatly improved the layout density of circuit boards, thereby reducing the size of electronic devices.

The advantage of SMT technology not only improves production efficiency but also makes the entire electronic manufacturing process more modern and efficient.

With the help of automated equipment, such as surface mount machines, surface mount devices can be installed quickly and accurately.

In general, the close relationship between surface mount technology and surface mount devices has promoted the rapid development of the electronics industry.

The trend of future electronic products will be smaller, lighter, and more powerful.