SMT PCB Board Separation process details:

1. Carefully select the board splitter

In the SMT board separation process, selecting a PCB board separation machine is crucial.

Engineers should carefully evaluate different types of board separation machines, such as knife-type, saw-blade type, and guillotine type, based on the printed circuit board features, such as the size, thickness, and material.

We should be sure that the selected machine is a perfect match for production needs to increase efficiency and reduce costs.

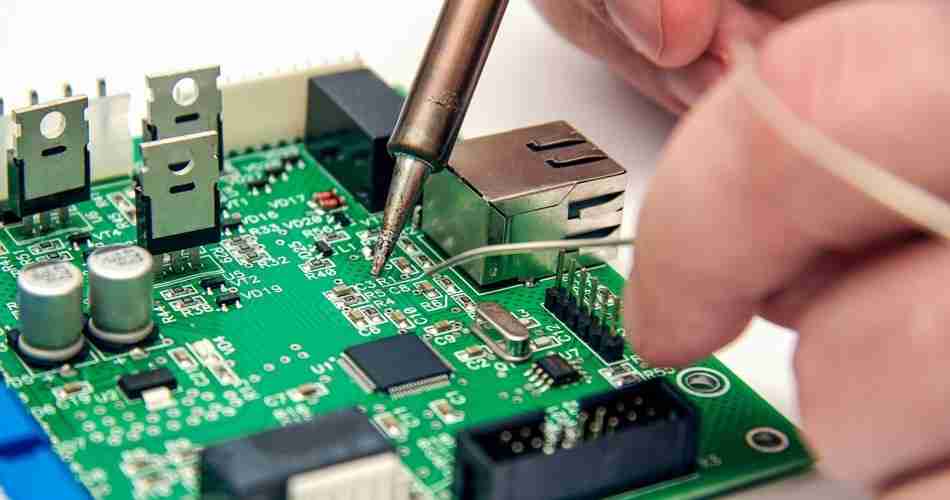

2. Ensure the quality of circuit board assembly

The quality of board separation is directly affected by the quality of PCB assembly.

It ensures that the solder joints are firm and reliable and the pads are flat and smooth to guarantee the reliability of component connections and prevent producing problems during the board separation.

3. Comprehensive security protection:

Since SMT splitting produces a lot of debris and smoke, engineers must do a good job of safety protection.

Wear protective glasses, masks, gloves, and other equipment to ensure the personal safety of staff.

4. Strictly implement operating procedures:

During the SMT panel separation stage, strict implementation of operating procedures is a significant step to ensure the smooth progress of the entire process.

Operations that comply with regulations can effectively prevent potential accidents and ensure the safety of the production environment.

Specific operation details:

1. Before board separation, carefully check the circuit board’s size, thickness, and material to ensure that it meets the requirements of the board separation machine.

2. When board separation, fix the circuit board on the board separation machine to prevent unnecessary movement.

3. Control the speed of the board separation machine to avoid board separation too quickly, which may cause the solder joints to break or other damage.

4. After board separation, carefully inspect the circuit boards to ensure that board separation meets the quality standards.

Strictly following the above details and operating suggestions can ensure the SMT sub-boards safety and high quality, thereby improving the overall production efficiency and ensuring the reliability of the final product. These measures play a crucial role in optimizing the SMT PCB board separation process.