PCBs are utilized to support and connect electrical elements in electronic items. They are usually made of copper, material, and substratum. The efficiency and toughness of a PCB are directly related to its dimension and number of layers. Adding more layers to a PCB raises its functionality. This has substantial advantages in the electronic devices market.

1. Single-layer PCB

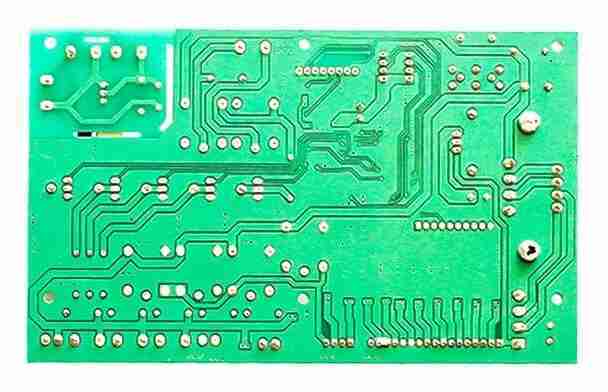

A single-layer published motherboard (PCB) is a kind of circuit board that has only a slim coating of conductive product (generally copper) on one portion of the board. The other section acts as a connection point for numerous digital components.

For that reason, electrical limits, fills up, adapters, elements, cables, placing holes, vias, and pads are all manufactured making use of a single-layer PCB substrate, a conductive metal layer, a silk display, and a safety solder mask.

In spite of the arrival of advanced modern technologies, the electronic devices industry still counts heavily on single-layer PCBs.

2. Benefits of single-sided boards

Inexpensive of SMT manufacturing

Much easier to develop and much less susceptible to errors

Because there is just one layer, soldering, placing, and electronic boring elements are basic.

Good option for minimalist formats

Cost-effective for mass production of consumer electronic devices

Best choice for quick, automation.

3. Drawbacks of Single-Layer PCBs

The advantages of single-layer PCBs are that they are basic and economical to create. Yet they likewise have some drawbacks that users need to recognize.

Lack of space and pins for connections on printed motherboard where numerous elements are called for.

Reduced speed and performance.

As functionality increases, weight and size likewise increase, minimizing the portability of the tool.