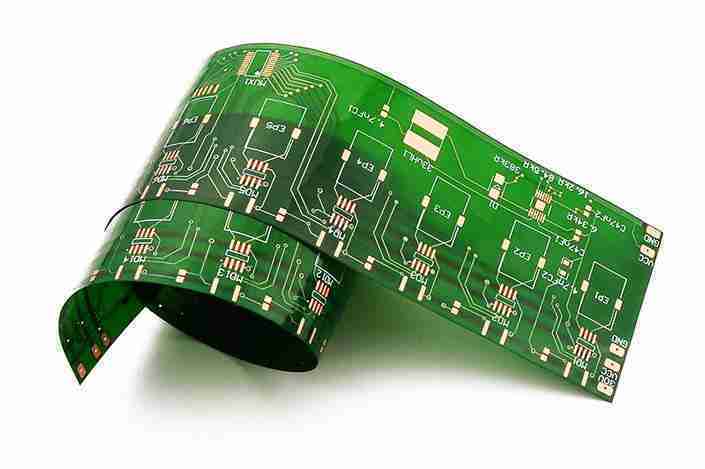

Flexible printed circuit boards (PCBs) are bringing revolution in the electronics industry. Like traditional rigid PCBs, flexible PCBs are mentioned for special shapes and acclimate, making them perfect for various applications in advanced innovation. This article investigates the preferences of utilizing flexible PCBs and how they contribute to upgraded execution in electronic devices.

1. Space-Saving and Compact Design

One of the most important preferences of flexible PCB is his ability to quit space. This ability makes them perfect for cutting small gadgets such as smart phones, wearable and medical gadgets. Their compact nature permits creators to make lighter and littler items without compromising performance.

2. Upgraded Plan Flexibility

Flexible PCBs provide remarkable plan flexibility, allow engineers to make circuits that adjust interesting shapes and forms. This Flexible strengthens the advancement of imaginative electronic gadgets that will be infallible with unbending PCBs. Whether it’s a bended show, foldable gadget, or wearable sensor, flexible PCBs permit for the integration of complex plans that upgrade client involvement and functionality.

3. Moved forward Solidness and Reliability

This makes them exceedingly dependable for applications uncovered to visit development, such as car gadgets, aviation frameworks, and mechanical apparatus. The nonattendance of mechanical connectors moreover decreases potential disappointment focuses, guaranteeing a longer lifespan.

4. Lightweight Construction

Weight decrease is a basic figure in present day electronic plan, particularly for versatile gadgets and aviation applications. Flexible PCBs are lighter than conventional unbending PCBs due to their negligible utilize of connectors, wiring, and patch joints. This diminishment in weight contributes to vitality effectiveness and makes strides in general gadget execution, making them a favoured choice for producers centred on lightweight solutions.

5. Way better Warm Dissipation

Thermal management is pivotal for electronic gadgets, as intemperate warm can lead to execution debasement and component disappointment. Flexible PCBs have prevalent warm scattering properties compared to rigid PCBs. Their lean and flexible layers permit for superior warm dissemination, lessening the hazard of overheating. This advantage makes them perfect for high-power applications such as Driven lighting, control gadgets, and automotive components.

6. Diminished Assembly Time and Cost

Flexible PCBs dispose of the require for broad wiring and connectors, decreasing gathering time and costs. Conventional unbending PCBs regularly require numerous connectors and patch joints, which increment labor costs and the hazard of absconds. Flexible PCBs, on the other hand, streamline the fabricating prepare by coordination different circuits into a single flexible layer. This rearrangements not as it were diminishes costs but too improves unwavering quality by minimizing potential disappointment points.

7. High Resistance to Environmental Factors

Flexible PCBs are planned to withstand unforgiving natural conditions, counting extraordinary temperatures, stickiness, and introduction to chemicals. This flexibility makes them appropriate for military, aviation, and mechanical applications where toughness is a basic necessity. Their capacity to persevere challenging situations without execution debasement guarantees unwavering quality in mission-critical applications.

8. Improved Flag Integrity

Signal astuteness is basic in high-speed electronic applications, and flexible PCBs offer prevalent execution in this respect. The nonattendance of numerous connectors and interconnects diminishes flag misfortune and electromagnetic obstructions (EMI). This advantage makes flexible PCBs an amazing choice for information transmission applications, broadcast communications, and medical gadgets where accuracy and precision are paramount.

9. Integration of Different Functions

Flexible PCBs permit for the integration of numerous electronic capacities inside a single layer. This multi-functionality disposes of the require for extra circuit boards, decreasing complexity and upgrading productivity. Gadgets such as restorative inserts, IoT gadgets, and high-tech buyer gadgets advantage from this integration, as it leads to progressed execution and decreased fabricating costs.

10. Perfect for Energetic Applications

Some electronic applications require circuits that can withstand persistent twisting, extending, or flexing. Flexible PCBs are particularly outlined to handle these energetic conditions without compromising execution. Applications such as automated arms, flexible shows, and biomedical wearables depend on flexible PCBs to keep up usefulness whereas persevering consistent movement.

11. Eco-Friendly Manufacturing

As the gadgets industry moves towards maintainability, flexible PCBs contribute to eco-friendly fabricating hones. Their capacity to decrease fabric squander, dispense with over the top wiring, and lower control utilization adjusts with green activities. Also, their long life expectancy diminishes electronic squander, making them a more maintainable alternative compared to conventional rigid PCBs.

12. Bolsters High-Density Applications

Flexible PCBs can oblige high-density component arrangement, empowering more complex circuit plans in a littler impression. This advantage is vital for present day innovation, where gadgets require expanded usefulness without extending in measure. From high-performance computing to progressed restorative electronics, flexible PCBs empower producers to thrust the boundaries of electronic design.

13.Reduction in Electromagnetic Interference (EMI)

The compact and streamlined plan of flexible PCBs minimizes the chance of electromagnetic obstructions, which is pivotal for keeping up flag clarity and avoiding disturbances in delicate electronic frameworks. This highlight is especially imperative in communication frameworks, medical gadgets, and military applications, where flag astuteness is a best priority.

14. Improved Aesthetic and Ergonomic Designs

Flexible PCBs contribute to the smooth and ergonomic plan of advanced electronic gadgets. Their lean profile and flexible nature permit for consistent integration into customer items, coming about in stylishly satisfying and user-friendly plans. This advantage is especially advantageous in customer electronics, where compactness and visual request play a critical part in item success.

15. Customization for Particular Applications

Flexible PCBs can be custom-made to meet the special necessities of particular applications. Engineers can plan circuits with shifting levels of adaptability, thickness, and layer arrangements to optimize execution for particular utilize cases. This customization capability is especially important in businesses such as medical gadgets, aviation, and defense, where exact usefulness is required.

Conclusion

Flexible PCBs are a game-changer in the gadgets industry, advertising various preferences over conventional rigid PCBs. Their compact plan, toughness, lightweight nature, and prevalent warm management make them perfect for different applications, counting customer gadgets, car, aviation, restorative gadgets, and mechanical mechanization. By lessening Assembly time, improving flag astuteness, and supporting inventive plans, flexible PCBs proceed to drive mechanical progressions. As request for littler, more proficient, and solid electronic gadgets increments, the selection of flexible PCBs will without a doubt proceed to develop, forming the future of electronics.