With the rapid advancement of contemporary electronic infotech, PCB production technology has actually likewise transformed greatly, and the needs for product innovation are obtaining greater and greater. Similar to the circuit boards in smart phones and computers currently, some use gold and copper, that makes the benefits and drawbacks of circuit card extra evident.

Circuitcardassembly aids everybody to understand the surface innovation on printed circuit boards and contrasts the benefits and drawbacks of different PCB surface area therapy processes and relevant scenarios.

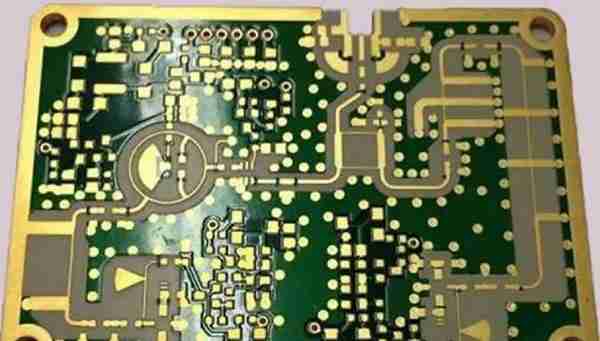

From the appearance of the board processed by PCB, its appearance generally has 3 colors: gold-silver-light red. Concerning classification, gold is the most costly, silver is 2nd, and the most inexpensive is light red. It is very easy to see from the look whether the manufacturer has actually cut corners. The parts of the motherboard are primarily pure copper, referred to as bare copper board.

1. The advantage of bare copper board is that the price is relatively reduced, the surface area is level, and its weldability is much better without oxidation. However beware not to be influenced by acid and temperature level. Copper is simple to oxidize airborne after being put for a very long time.

2. The gold on the immersion gold board is gold. Even if just a slim layer of conductor is layered, the cost of this has made up 10% of the expense of the entire circuit board. After immersion in gold therapy, it is difficult to oxidize, can be stored for a very long time, and has a smoother surface. It appropriates for welding some fine-gap pins and some devices with smaller sized solder joints, such as smart phone boards. Its cost is relatively high and the welding toughness is relatively poor.

3. The tin-spraying circuit card is silver. It sprays a layer of tin outside of the copper circuit. It can aid with welding, yet it can not have the same lasting call dependability as gold. It is very easy to oxidize and corrosion if utilized for a long period of time, causing inadequate get in touch with. It is often utilized on the circuit card of some little electronic products, and its price is cheap.

4. In the SMT factory, the OSP process board is additionally called organic change movie. Due to the fact that it is an organic substance, not a metal material, it is more affordable than the tin-spraying process.

It has all the advantages of bare copper plate welding. Also ended circuit boards can be dealt with once more on the surface, but they are easily influenced by acid and moisture. If the storage space time is too long, greater than 3 months, the surface therapy need to be done again. OSP is an insulating layer, so the test point needs to be published with solder paste to get rid of the initial OSP layer before the pinpoint can be gotten in touch with for electrical testing.