Printed Circuit Boards (PCBs) are the spine of cutting edge electronic gadgets, serving as the establishment on which components like resistors, capacitors, and coordinates circuits are mounted. The innovation behind PCBs has advanced over a long time, driving to the improvement of different specialized instruments and forms that guarantee the proficient fabricating and working of these sheets.

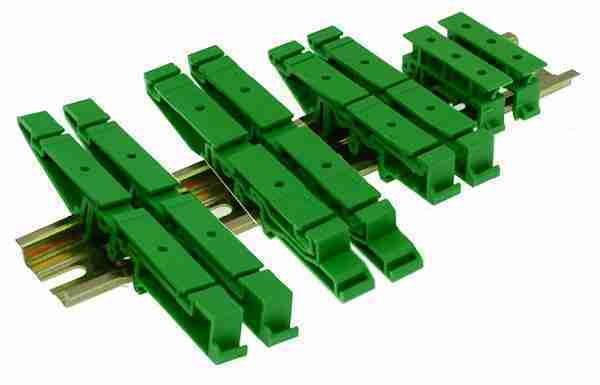

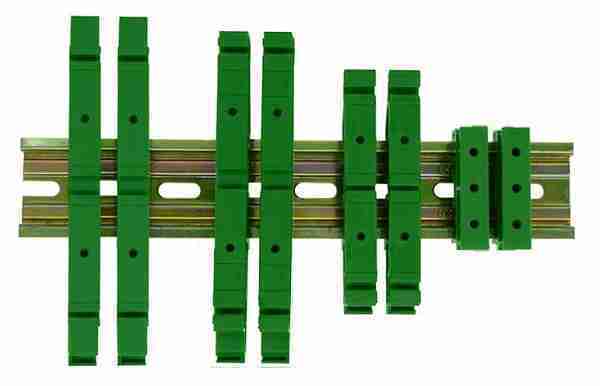

A PCB Pinner is regularly an installation or apparatus utilized to embed and hold components (like through-hole components) on a PCB amid the get together handle. It makes a difference keep the components adjusted and settled in put, anticipating them from moving amid the fastening prepare. One such device that plays a vital part in the PCB fabricating handle is the PCB pinner.

This article will dig into the concept of a PCB pinner, its noteworthiness, usefulness, sorts, and the effect it has on the PCB fabricating industry.

The Role of PCB Pinners in Manufacturing

To get it the significance of PCB pinners, it’s basic to have a get a handle on of the PCB fabricating prepare. PCBs are ordinarily made by laminating layers of copper onto a non-conductive substrate, taken after by carving absent overabundance copper to frame electrical pathways. Components are at that point mounted on the board, and associations are made either through patching or other methods.

PCB pinners are utilized to secure the components to the board amid gathering, guaranteeing that they remain in put whereas the fastening prepare happens. They act as transitory holders or installations that keep components adjusted and appropriately situated. This arrangement is significant for the computerized fastening forms like Surface Mount Innovation (SMT) or through-hole patching, where exactness is crucial to maintain a strategic distance from absconds and guarantee the unwavering quality of the PCB.

Functionality of PCB Pinners

PCB pinners come in different plans and functionalities, depending on the particular necessities of the PCB get together handle. The fundamental work of a PCB pinner is to hold components in put, but the way this is accomplished can vary.

1. Mechanical Pinners: These are the most common sort of PCB pinners and depend on physical constrain to hold components input. They are ordinarily made of materials like stainless steel or high-strength plastic. Mechanical pinners are embedded into pre-drilled gaps on the PCB, where they grasp the component leads or edges, avoiding development amid soldering.

2. Vacuum Pinners: Vacuum pinners utilize suction to hold components in put. They are especially valuable for sensitive or little components that might be harmed by mechanical weight. Vacuum pinners make a vacuum around the component, securing it to the board without applying coordinate force.

3. Magnetic Pinners: These pinners utilize attractive areas to hold components input. They are commonly utilized in scenarios where components have metallic properties that can be pulled in to a magnet. Attractive pinners offer the advantage of simple situation and evacuation, making them perfect for brief holding.

4. Adhesive Pinners: Cement pinners utilize a little sum of cement to hold components in put briefly. This strategy is regularly utilized when working with components that have sporadic shapes or when tall accuracy is required. The cement is regularly non-conductive and can be effectively expelled after the fastening process.

Types of PCB Pinners

The choice of PCB pinner depends on the particular needs of the get together handle, the sort of components being utilized, and the complexity of the PCB plan. Underneath are a few common sorts of PCB pinners:

1. Through-Hole Pinners: These pinners are planned for utilize in through-hole PCB gathering, where components have leads that pass through gaps in the board. Through-hole pinners secure the leads in put, guaranteeing that they do not move amid fastening. They are especially valuable for components with different leads, such as coordinates circuits.

2. Surface Mount Pinners: Surface mount innovation (SMT) is a prevalent strategy for mounting components specifically onto the surface of the PCB without the requirement for leads to pass through the board. Surface mount pinners are outlined to hold these components in put on the surface of the board, avoiding development amid reflow soldering.

3. High-Precision Pinners: A few PCB congregations require greatly tall accuracy, particularly in applications like aviation or therapeutic gadgets. High-precision pinners are outlined to hold components with a precision of microns, guaranteeing that indeed the littlest misalignment is dodged. These pinners are regularly utilized in conjunction with progressed situation machines that require exact component positioning.

4. Custom Pinners: In a few cases, off-the-shelf pinners may not meet the particular needs of a PCB gathering prepare. Custom pinners can be outlined and fabricated to fit special component shapes, board formats, or particular gathering necessities. These pinners are ordinarily created through collaboration between PCB originators and pinner manufacturers.

Advantages of Utilizing PCB Pinners

The utilized of PCB pinners offers a few focal points in the fabricating prepare, contributing to the by and large quality, productivity, and unwavering quality of PCBs. A few of these preferences include:

1. Improved Gathering Exactness: PCB pinners guarantee that components are precisely situated amid the get together handle, lessening the chance of misalignment. This exactness is significant for the legitimate working of the PCB, particularly in high-density plans where components are closely packed.

2. Reduced Surrenders: By holding components safely in put, PCB pinners minimize the event of absconds such as patch bridges, cold joints, or component development amid patching. This leads to a higher abdicate of useful PCBs and decreases the requirement for adjust or repairs.

3. Enhanced Handle Proficiency: PCB pinners streamline the gathering prepare by permitting for quicker and more dependable component arrangement. Robotized get together machines can work more productively when components are safely held in put, driving to expanded throughput and diminished cycle times.

4. Versatility in Component Dealing with: PCB pinners can be utilized with a wide extend of components, from expansive connectors to modest surface-mount gadgets. This flexibility makes them a profitable device in different PCB get together forms, catering to distinctive board plans and component types.

5. Cost-Effective Arrangement: The utilized of PCB pinners can diminish the by and large taken a toll of PCB fabricating by minimizing abandons, diminishing adjust, and progressing get together productivity. Whereas there may be a starting speculation in pinner devices or gear, the long-term investment funds in generation costs can be significant.

Challenges in PCB Pinner Implementation

While PCB pinners offer various benefits, there are too challenges related with their usage. These challenges can affect the adequacy of pinners in the get together handle and may require cautious thought amid the plan and fabricating phases.

1. Component Compatibility: Not all components are consistent with standard PCB pinners. A few components may have unpredictable shapes, sensitive structures, or interesting mounting prerequisites that make it troublesome to utilize customary pinners. In such cases, custom pinners or elective holding strategies may be necessary.

2. Board Plan Imperatives: The plan of the PCB itself can force imperatives on the utilized of pinners. For case, thickly stuffed sheets with restricted space between components may not have sufficient room for mechanical pinners. Creators must consider the arrangement of pinners amid the PCB format stage to guarantee that they do not meddled with other components or circuitry.

3. Adhesive Buildup: In cases where cement pinners are utilized, there is a chance of taking off behind buildup on the PCB after the components are expelled. This buildup can influence the execution of the board, particularly in high-frequency or delicate applications. Cautious choice of cement materials and appropriate cleaning strategies are vital to relieve this issue.

4. Manufacturing Resilience: The viability of PCB pinners depends on the fabricating resistances of both the pinners and the PCB. Varieties of gap sizes, component lead measurements, or board thickness can affect the fit and work of pinners, driving to irregularities in the get together process.

5. Cost Contemplation: Whereas PCB pinners can lead to long-term fetched reserve funds, there is a starting speculation required for the buy of pinner instruments or gear. Moreover, custom pinners may include higher costs due to the requirement for specialized plan and fabricating. Producers must weigh these costs against the benefits of made strides gathering accuracy and diminished defects.

Applications of PCB Pinners in Industry

PCB pinners are utilized over a wide extend of businesses where solid and exact PCB gathering is basic. A few of the key applications of PCB pinners include:

1. Consumer Hardware: PCB pinners are commonly utilized in the get together of shopper hardware, such as smartphones, tablets, and wearables. These gadgets require compact and thickly pressed PCBs, making pinners basic for guaranteeing exact component arrangement and soldering.

2. Automotive Industry: The car industry depends intensely on PCBs for different electronic frameworks, counting motor control units (ECUs), infotainment frameworks, and progressed driver-assistance frameworks (ADAS). PCB pinners play a pivotal part in the gathering of these sheets, guaranteeing that components are safely mounted and adjusted for ideal performance.

3. Aerospace and Defense: In aviation and defense applications, PCBs must meet exacting unwavering quality and execution measures. PCB pinners are utilized to accomplish the tall accuracy required for these applications, where indeed minor absconds can have genuine consequences.

4. Medical Gadgets: Restorative gadgets frequently consolidate PCBs in their plan, and the unwavering quality of these sheets is fundamental. PCB pinners are utilized to guarantee that components are precisely put and safely mounted, minimizing the hazard of absconds that may compromise the security or adequacy of the device.

5. Telecommunications: The broadcast communications industry depends on PCBs for a wide extend of applications, from organize framework to versatile gadgets. PCB pinners offer assistance guarantee the solid gathering of these sheets, contributing to the general execution and solidness of broadcast communications equipment.

Future Patterns in PCB Pinner Technology

As the gadgets’ industry proceeds to advance, so as well does the innovation behind PCB pinners. A few patterns are forming the future of PCB pinner innovation, driven by the requirement for more noteworthy exactness, effectiveness, and flexibility in PCB assembly.

1. Automation and Mechanical technology: The integration of computerization and mechanical autonomy in PCB get together is driving the advancement of more progressed and exact PCB pinners. Computerized frameworks can put pinners with more noteworthy exactness and consistency, diminishing the probability of absconds and moving forward by and large get together efficiency.

2. Miniaturization: The drift towards littler and more compact electronic gadgets is pushing the boundaries of PCB plan and gathering. PCB pinners are being created to oblige the miniaturization of components, empowering the gathering of high-density sheets with littler and more sensitive parts.

3. Material Development: Propels in materials science are driving to the improvement of modern pinner materials that offer made strides quality, strength, and compatibility with different components. For illustration, lightweight and heat-resistant materials are being investigated for utilize in high-temperature fastening processes.

4. Customizability and Adaptability: The request for customized PCB plans is driving the requirement for more adaptable and versatile PCB pinners. Producers are creating pinners that can be effectively balanced or altered to suit distinctive board formats and component sorts, advertising more noteworthy flexibility in the gathering process.

5. Sustainability and Natural Contemplation: As natural concerns proceed to develop, the hardware industry is progressively centering on maintainability. PCB pinner innovation is advancing to join eco-friendly materials and forms, diminishing squander and minimizing the natural affect of PCB manufacturing.

Conclusion

PCB pinners are a fundamentally portion of the PCB fabricating prepare, playing a significant part in guaranteeing the exact and dependable get together of electronic components. From holding components in put to making strides gathering exactness, lessening absconds, and improving handle proficiency, PCB pinners offer various benefits that contribute to the in general quality and execution of PCBs.

As the hardware industry proceeds to advance, PCB pinner innovation is moreover progressing to meet the requests of cutting edge PCB get together. With patterns like robotization, miniaturization, fabric advancement, and supportability forming the future of PCB pinners, these instruments will proceed to play a crucial part in the fabricating of high-quality electronic gadgets over different industries.

Understanding the distinctive sorts of PCB pinners, their functionalities, and their applications is fundamental for anybody included in PCB plan and fabricating. By leveraging the points of interest of PCB pinners and tending to the related challenges, producers can accomplish more prominent accuracy, productivity, and unwavering quality in their PCB gathering forms, eventually driving to the generation of predominant electronic gadgets.