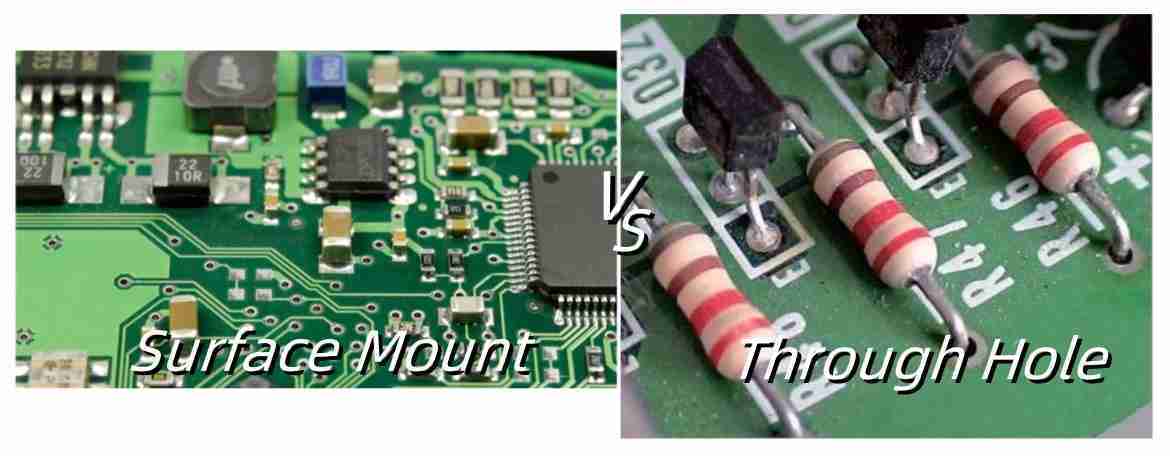

SMT vs THT

SMT (surface mount technology) is one of the most popular production processes in the electronic assembly industry. It is widely used in the lightweight and high-volume production needs of mobile phones and computers.

PCB assembly made of SMT has the characteristics of high density and lightweight. It realizes automated mass production.

The solder joints and components are on the same plane of the upper board surface, and the reflow soldering process is adopted.

In contrast, THT (Throughput Technology) is still not easily replaced by SMT in the automotive electronics industry.

However, THT has been replaced gradually in the consumer electronics industry.

The components on the PCBA made by the THT process are farther apart, and the board area is larger. The components and solder joints are located on both sides of the board.

Use wave soldering and other soft soldering techniques to form reliable solder joints.

The fundamental difference between SMT and THT lies in the assembly methods: “sticking” and “insertion”.

THT uses leaded components to establish mechanical and electrical connections by inserting pins into pre-drilled holes on the PCB and then wave soldering on the other side.

However, as circuits become denser, the use of leads limits the reduction in the size of circuit boards.

Surface mounting technology refers to placing sheet-like components or miniaturized components suitable for surface mounting on the surface of a printed circuit board according to the requirements of the circuit.

It is a PCB assembly technology that forms electronic components with certain functions through soldering processes such as reflow or wave soldering.

On SMT circuit boards, solder joints, and components are located on the same side, and through holes are used to connect the wires on both sides of the circuit board, thereby improving assembly density.

In summary, SMT has significant advantages in lightweight and mass production, while THT still has irreplaceable advantages in some specific application fields.

With the continuous development of technology, as the mainstream electronic assembly technology, SMT will be further expanded in various fields.