What Is PCB Assembly? How to Assemble PCBs and Why It Matters for Electronics?

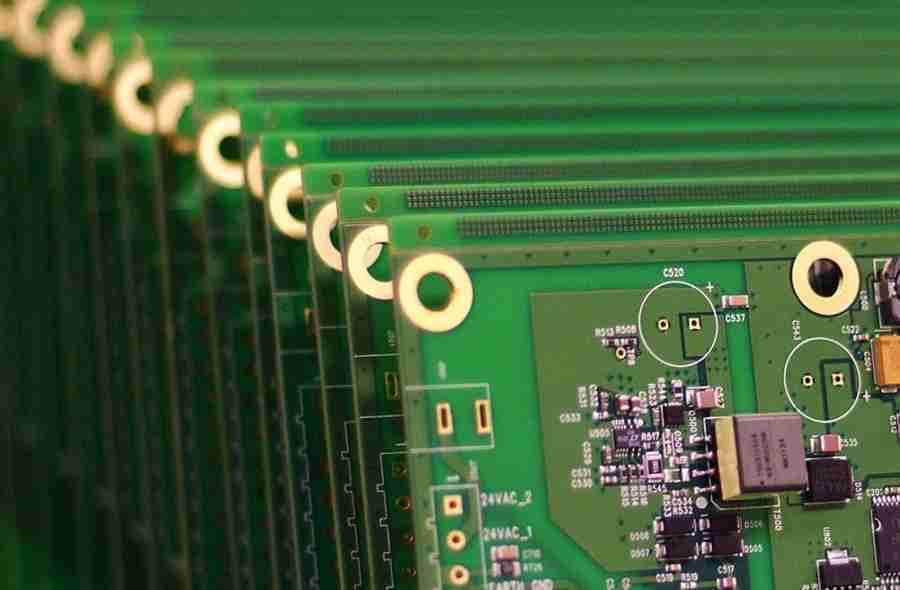

Printed Circuit Board (PCB) Assembly plays a essential part in the cutting edge hardware industry, serving as the spine for all electronic gadgets. This handle, regularly alluded to as PCB Assembly or PCBA, includes mounting electronic components onto a created PCB to make a utilitarian amassed circuit board. This direct investigates what PCB assembly involves, the steps to gather PCBs, and its basic significance in electronics.

Understanding PCB Assembly

A Printed Circuit Board is a covered board composed of non-conductive substrate fabric, layered with copper follows that build up associations between electronic components. In any case, a PCB alone is not useful; it requires the assembly of electronic components to make a working gadget. This handle, named PCB Assembly, changes a uncovered PCB into an operational component of electronic devices.

PCB assembly can include either through-hole technology (THT), surface mount technology (SMT), or a combination of both. Each technology has particular applications and points of interest, making the choice subordinate on the plan and utilitarian necessities of the electronics.

The Process of Assembling PCBs

1. Planning of the PCB and Components

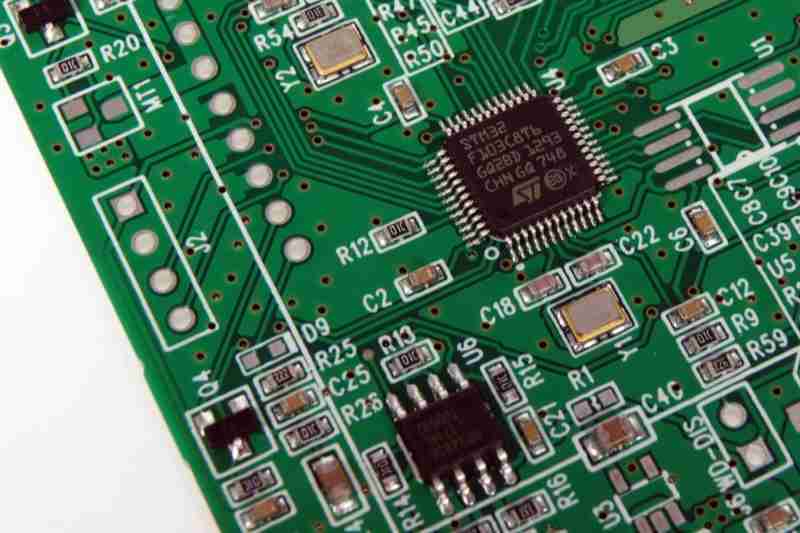

The assembly prepare starts with sourcing the components recorded in the bill of materials (BOM). These incorporate resistors, capacitors, diodes, microchips, and other electronic components. At the same time, the uncovered PCB is created to coordinate the plan details, guaranteeing the copper follows adjust with the expecting layout.

2. Solder Paste Application

For SMT-based PCB assembly, patch glue is connected to the surface of the PCB at focuses where components will be mounted. This glue, a blend of powdered patch and flux, holds the components in put incidentally some time recently soldering.

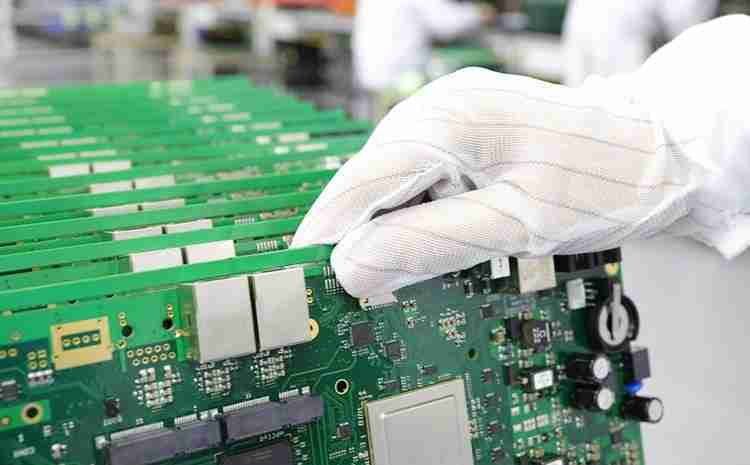

3. Component Placement

Automatic pick-and-place machines position the electronic components on the PCB. These machines are exceedingly exact, competent of setting components on perplexing plans inside milliseconds. For THT assembly, components are physically or robotically embedded into the penetrated holes.

4. Soldering Process

• Reflow Fastening (SMT): After component arrangement, the PCB is passed through a reflow broiler. Controlled warm dissolves the patch glue, making changeless electrical and mechanical connections.

• Wave Fastening (THT): For through-hole components, the PCB is passed over a wave of liquid patch, fastening all uncovered ranges and securing components to the board.

5. Inspection and Quality Control

Thorough assessment guarantees that the collected circuit board meets the required determinations. Strategies such as optical inspection (AOI), X-ray assessment, and utilitarian testing offer assistance recognize any deficiencies or misplacements.

6. Final Assembly and Testing

Once the components are patched and reviewed, the PCB experiences last assembly. Extra parts, like connectors and chassis, may be included. Testing guarantees the completed PCB capacities as expecting, assembly quality and execution standards.

Why PCB Assembly Things for Electronics

1. Empowers Compact Design

Modern hardware request compactness and usefulness. PCB assembly permits originators to make perplexing circuits on negligible space, coordination different functionalities into a little impression. Methods like SMT diminish the measure of components, making it conceivable to create lightweight and versatile devices.

2. Guarantees Unwavering quality and Performance

A legitimately collected PCB ensures steady associations and vigorous execution. Progressed fastening strategies guarantee components remain safely in put, indeed beneath mechanical push or tall temperatures, improving the life span of electronic devices.

3. Speeds Up Production

Automation in PCB assembly, counting pick-and-place machines and reflow fastening stoves, drastically increments generation speed. This is pivotal for businesses like customer hardware and broadcast communications, where request for unused items is constant.

4. Diminishes Costs

Efficient PCB Assembly brings down generation costs by minimizing blunders, diminishing fabric wastage, and expanding throughput. The prepare moreover underpins adaptability, permitting producers to meet request without over the top expenditure.

5. Fundamental for Innovative Advancements

PCBs are the establishment of advancement in businesses extending from healthcare to aviation. High-quality amassed circuit sheets are irreplaceable in creating cutting-edge advances like IoT gadgets, restorative hardware, and space investigation tools.

Types of PCB Assembly

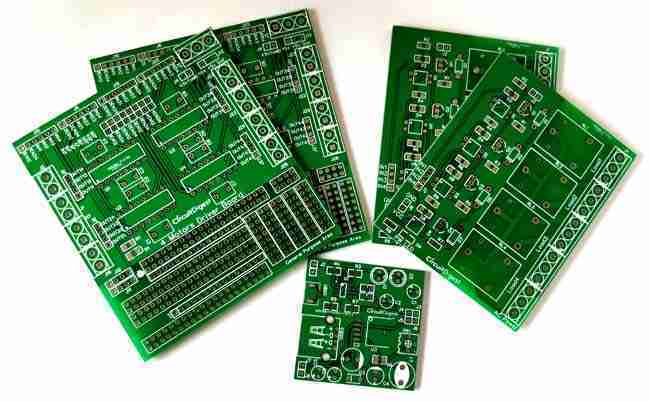

1. Single-Sided Assembly

Single-sided PCB Assembly includes putting components on one side of the board. This sort is cost-effective and suited for basic gadgets like calculators and Driven lighting systems.

2. Double-Sided Assembly

Here, components are mounted on both sides of the PCB, empowering more complex circuitry in a littler impression. It’s commonly utilized in domestic machines and communication devices.

3. Multi-Layer Assembly

Multi-layer PCB Assembly joins numerous layers of circuitry, frequently sandwiched together. These PCBs are perfect for high-speed gadgets, servers, and progressed computing frameworks where space optimization and flag astuteness are critical.

Challenges in PCB Assembly

1. Miniaturization

As gadgets gotten to be littler, the measure of components and follow dividing on PCBs moreover decreases, making assembly profoundly challenging. Exactness devices and progressed procedures are fundamental to meet these demands.

2. Thermal Management

Heat scattering is basic in high-power gadgets. Destitute warm administration amid PCB Assembly can lead to overheating, component harm, and decreased gadget lifespan.

3. Quality Assurance

Even minor deficiencies, such as a single unsoldered association, can render a PCB out of commission. Hence, keeping up tall guidelines of quality control is non-negotiable.

Innovations in PCB Assembly

1. Progressed Materials

Innovative materials like adaptable PCBs and high-frequency substrates are growing the conceivable outcomes of electronic plan. These materials require specialized Assembly forms to handle their special characteristics.

2. Machine Learning and AI

AI and machine learning are upgrading assessment and quality control. These advances move forward imperfection discovery precision and decrease time-consuming manual reviews.

3. 3D Printing

3D printing in PCB assembly permits for quick prototyping and the improvement of complicated board plans, quickening item improvement timelines.

Best Practices for Assembling PCBs

• Select the Right Producer: Accomplice with an experienced PCB Assembly supplier who gets it your plan necessities and application needs.

• Optimize Design for Manufacturability (DFM): Guarantee the PCB format is outlined to encourage simple and cost-effective assembly.

• Perform Thorough Testing: Numerous levels of testing—from in-circuit to functional—can reveal potential issues early in the generation cycle.

• Invest in Training and Technology: Keeping up with industry progressions guarantees that the Assembly handle meets current requests and future-proof standards.

Conclusion

PCB Assembly is a foundation of the gadgets industry, giving the implies to change uncovered circuit sheets into useful components. From empowering the miniaturization of gadgets to guaranteeing unwavering quality and cost-efficiency, the handle is central to innovative advance. By understanding how to amass PCBs and why they matter, producers and engineers can thrust the boundaries of development, creating groundbreaking electronic arrangements for an interconnected world. The advancement of gathered circuit board forms proceeds to clear the way for more brilliant, more productive, and flexible gadgets.

Latest Blog

Table of Content

Contcat Us

Phone: +86-18123905375

Email: sales@circuitcardassembly.com

Skype: ali_youte

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Afrikaans

Afrikaans Shqip

Shqip አማርኛ

አማርኛ العربية

العربية Հայերեն

Հայերեն Azərbaycan dili

Azərbaycan dili Euskara

Euskara Беларуская мова

Беларуская мова বাংলা

বাংলা Bosanski

Bosanski Български

Български Català

Català Cebuano

Cebuano Chichewa

Chichewa 简体中文

简体中文 繁體中文

繁體中文 Corsu

Corsu Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Esperanto

Esperanto Eesti

Eesti Filipino

Filipino Suomi

Suomi Français

Français Frysk

Frysk Galego

Galego ქართული

ქართული Deutsch

Deutsch Ελληνικά

Ελληνικά ગુજરાતી

ગુજરાતી Kreyol ayisyen

Kreyol ayisyen Harshen Hausa

Harshen Hausa Ōlelo Hawaiʻi

Ōlelo Hawaiʻi עִבְרִית

עִבְרִית हिन्दी

हिन्दी Hmong

Hmong Magyar

Magyar Íslenska

Íslenska Igbo

Igbo Bahasa Indonesia

Bahasa Indonesia Gaeilge

Gaeilge Italiano

Italiano 日本語

日本語 Basa Jawa

Basa Jawa ಕನ್ನಡ

ಕನ್ನಡ Қазақ тілі

Қазақ тілі ភាសាខ្មែរ

ភាសាខ្មែរ 한국어

한국어 كوردی

كوردی Кыргызча

Кыргызча ພາສາລາວ

ພາສາລາວ Latin

Latin Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba Lëtzebuergesch

Lëtzebuergesch Македонски јазик

Македонски јазик Malagasy

Malagasy Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം Maltese

Maltese Te Reo Māori

Te Reo Māori मराठी

मराठी Монгол

Монгол ဗမာစာ

ဗမာစာ नेपाली

नेपाली Norsk bokmål

Norsk bokmål پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português ਪੰਜਾਬੀ

ਪੰਜਾਬੀ Română

Română Русский

Русский Samoan

Samoan Gàidhlig

Gàidhlig Српски језик

Српски језик Sesotho

Sesotho Shona

Shona سنڌي

سنڌي සිංහල

සිංහල Slovenčina

Slovenčina Slovenščina

Slovenščina Afsoomaali

Afsoomaali Español

Español Basa Sunda

Basa Sunda Kiswahili

Kiswahili Svenska

Svenska Тоҷикӣ

Тоҷикӣ தமிழ்

தமிழ் తెలుగు

తెలుగు ไทย

ไทย Türkçe

Türkçe Українська

Українська اردو

اردو O‘zbekcha

O‘zbekcha Tiếng Việt

Tiếng Việt Cymraeg

Cymraeg isiXhosa

isiXhosa יידיש

יידיש Yorùbá

Yorùbá Zulu

Zulu