What Makes Professional Printed Circuit Board Assembly Superior?

In the world of electronics, Printed Circuit Board Assembly (PCBA) is a pivotal handle that decides the unwavering quality and execution of electronic devices. Whether it is for consumer electronics, mechanical applications, restorative electronics, or military-grade gear, high-quality PCB Board Assembly guarantees ideal usefulness. But what makes proficient Circuit Card Assembly predominant? In this comprehensive Content, we will investigate the components that recognize proficient PCB Assembly administrations from substandard ones, counting exactness, quality control, materials, and mechanical advancements.

1. High-Quality Materials and Components

The establishment of prevalent Printed Circuit Board Assembly lies in the quality of the materials and components utilized. Proficient Assembly houses source components from legitimate providers, guaranteeing consistency, unwavering quality, and life span. High-quality PCBs use:

• Superior Substrate Materials: FR4, Rogers, and polyimide materials that offer toughness and warm resistance.

• High-Grade Patch: Lead-free or leaded patch with tall dissolving focuses to guarantee strong connections.

• Reliable Electronic Components: Resistors, capacitors, ICs, and connectors sourced from certified producers to maintain a strategic distance from fake parts.

• High-Quality Surface Wraps up: Such as ENIG (Electroless Nickel Submersion Gold), HASL (Hot Discuss Patch Leveling), and OSP (Natural Solder ability Additive), which make strides solder ability and anticipate oxidation.

Using top-tier materials in PCB Board Assembly improves solidness, minimizes disappointments, and guarantees long-term reliability.

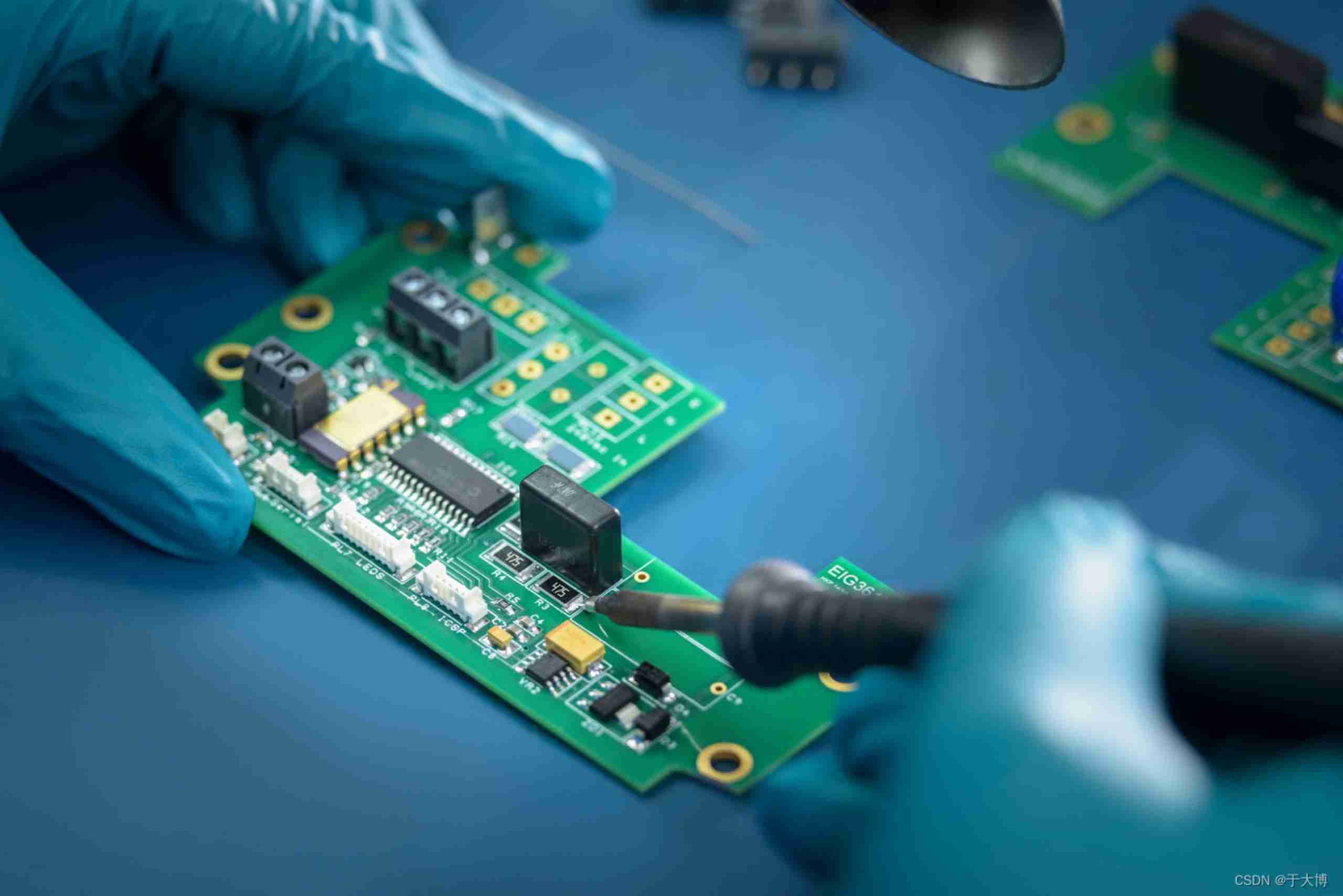

2. Accuracy in Manufacturing and Assembly

Professional Circuit Card Assembly utilizes exact Manufacturing methods to guarantee precise component arrangement and patching. The taking after progressed Manufacturing advances contribute to high-quality PCB assembly:

• Automated Pick-and-Place Machines: These machines guarantee exact arrangement of surface-mount electronics (SMDs) with negligible errors.

• Solder Glue Stenciling: Guarantees indeed application of patch glue for solid connections.

• Reflow Patching Handle: Gives controlled warming and cooling to shape secure patch joints.

• Wave Fastening (for Through-Hole Components): Ensures uniform patching for through-hole parts, improving mechanical stability.

Professional PCB Assembly forms keep up tight resistances, decreasing the chances of absconds and moving forward by and large performance.

3. Exacting Quality Control and Testing

One of the key differentiators of proficient Printed Circuit Board Assembly is thorough quality control and testing strategies. Industry-leading PCB Assembly companies execute the taking after testing strategies to ensure defect-free products:

• Automated Optical Inspection (AOI): Employments high-resolution cameras to distinguish misalignments, lost components, and fastening defects.

• X-ray Assessment: Permits for inside review of patch joints, especially for Ball Lattice Clusters (BGAs) and other covered up connections.

• In-Circuit Testing (ICT): Checks person component usefulness and connectivity.

• Functional Testing (FCT): Mimics real-world working conditions to confirm generally PCB performance.

• Burn-In Testing: Uncovered the PCB to drawn out operational stretch to distinguish early failures.

Through broad quality control measures, proficient PCB producers guarantee unwavering quality, minimizing the chance of field failures.

4. Compliance with Industry Standards

Professional PCB Board Assembly follows to strict industry guidelines to ensure security, execution, and administrative compliance. These measures include:

• IPC-A-610: The industry standard for PCB Assembly adequacy, guaranteeing high-quality fastening and component placement.

• ISO 9001: Certification for quality administration frameworks in manufacturing.

• UL Certification: Guarantees fire security and unwavering quality of PCB materials.

• RoHS Compliance: Guarantees the utilize of ecologically neighborly, lead-free components.

• MIL-STD-810: For military-grade PCB congregations requiring tall durability.

Compliance with these measures guarantees that proficient PCB Assemblys meet security and operational prerequisites for different industries.

5. Progressed Manufacturing Techniques

The predominant execution of proficient Circuit Card Assembly is generally credited to cutting-edge Manufacturing strategies, including:

• Surface-Mount Technology (SMT): Empowers high-density component situation with made strides electrical performance.

• Through-Hole Technology (THT): Guarantees strong mechanical associations for components requiring tall durability.

• Hybrid Assembly: Coordinating both SMT and THT to meet particular application needs.

• Multilayer PCB Manufacturing: Permits for high-complexity plans with made strides flag integrity.

• Flexible and Rigid-Flex PCBs: Give upgraded plan flexibility for compact and energetic applications.

By consolidating these progressed strategies, proficient PCB producers deliver high-performance congregations custom-made to differing applications.

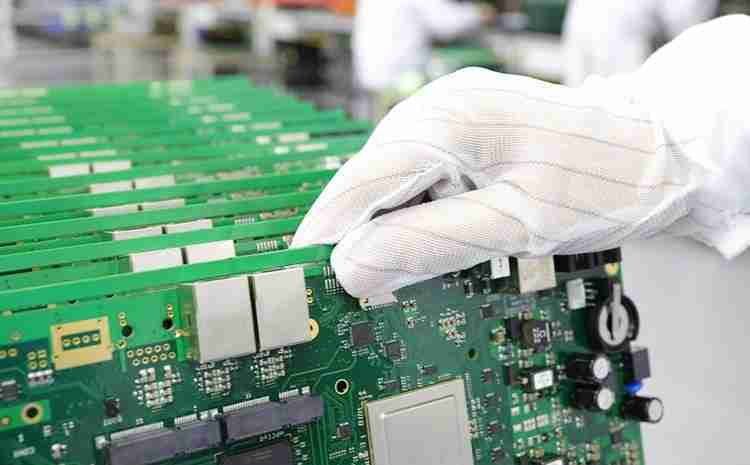

6. Proficient Supply Chain and Component Sourcing

Superior PCB Assembly depends on an productive supply chain to guarantee convenient conveyance and cost-effectiveness. Proficient PCB producers leverage:

• Established Provider Connections: Secure dependable components from trusted sources.

• Inventory Administration Frameworks: Decrease lead times and maintain a strategic distance from generation delays.

• Counterfeit Component Location: Execute exacting screening forms to anticipate the utilize of fake or subpar parts.

• Global Sourcing Systems: Guarantee get to to uncommon or specialized components.

A well-managed supply chain minimizes disturbances and ensures high-quality congregations without delays.

7. Customization and Plan Support

Professional PCB Assembly administrations offer comprehensive customization and plan back to optimize execution. This includes:

• Design for Manufacturability (DFM) Examination: Recognizes potential plan issues some time recently production.

• Design for Testability (DFT) Techniques: Guarantees effective testing and debugging.

• Prototyping Administrations: Gives fast emphasess to refine designs.

• Bespoke PCB Formats: Tailors PCBs to particular utilitarian and mechanical requirements.

Customization administrations empower clients to accomplish ideal PCB execution for their one of a kind applications.

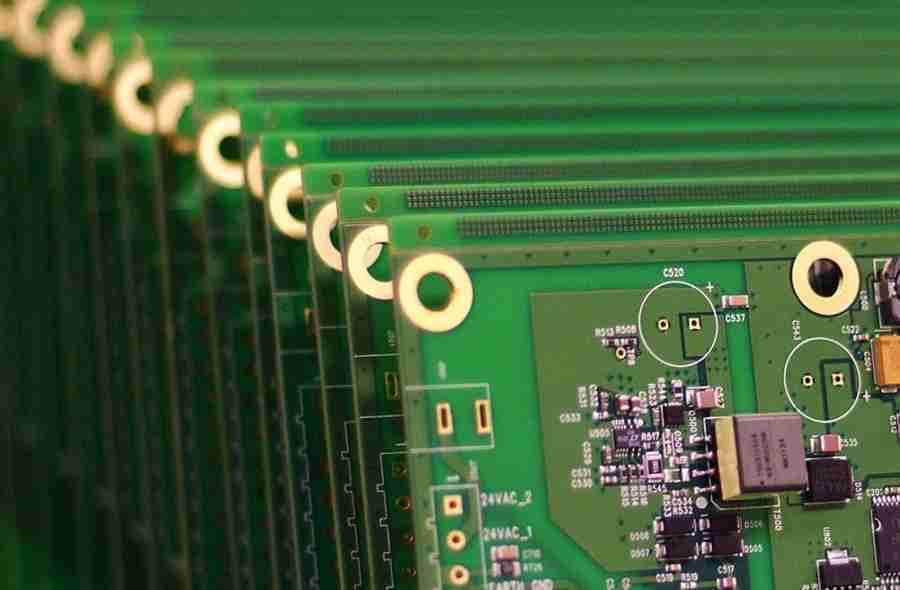

8. Versatility and Generation Capabilities

Another figure that makes proficient Printed Circuit Board Assembly prevalent is the capacity to scale generation based on request. Whether for little bunch models or full-scale generation, top-tier PCB Assembly houses offer:

• Low-Volume and High-Mix Generation: Bolsters fast prototyping and specialized projects.

• Mass Generation Capabilities: Guarantees reliable quality in large-scale manufacturing.

• Fast Turnaround Administrations: Meets pressing generation timelines without compromising quality.

Scalability guarantees that businesses can depend on proficient PCB producers to meet their advancing generation needs efficiently.

9. Cost-Effectiveness in the Long Run

While proficient PCB Assembly administrations may have a higher beginning taken a toll, they give critical long-term investment funds due to:

• Reduced Disappointment Rates: High-quality Manufacturing minimizes expensive adjust and item recalls.

• Improved Vitality Proficiency: Optimized circuits devour less control, lessening operational costs.

• Enhanced Item Life span: Strong congregations lower substitution and support costs.

• Minimized Downtime: Solid PCBs anticipate startling framework disappointments and disruptions.

Investing in proficient PCB Assembly eventually leads to lower add up to fetched of possession and higher return on investment.

Conclusion

Professional Printed Circuit Board Assembly stands out due to its commitment to high-quality materials, accuracy Manufacturing, exacting quality control, industry compliance, progressed advances, proficient supply chain administration, customization, adaptability, and cost-effectiveness. Whether you require a model or high-volume generation, choosing a legitimate PCB Assembly supplier guarantees prevalent execution and reliability.

By selecting for proficient Circuit Card Assembly, businesses can maximize the proficiency, solidness, and usefulness of their electronic items, setting the establishment for long-term victory in competitive markets.

Latest Blog

Table of Content

Contcat Us

Phone: +86-18123905375

Email: sales@circuitcardassembly.com

Skype: ali_youte

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Afrikaans

Afrikaans Shqip

Shqip አማርኛ

አማርኛ العربية

العربية Հայերեն

Հայերեն Azərbaycan dili

Azərbaycan dili Euskara

Euskara Беларуская мова

Беларуская мова বাংলা

বাংলা Bosanski

Bosanski Български

Български Català

Català Cebuano

Cebuano Chichewa

Chichewa 简体中文

简体中文 繁體中文

繁體中文 Corsu

Corsu Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Esperanto

Esperanto Eesti

Eesti Filipino

Filipino Suomi

Suomi Français

Français Frysk

Frysk Galego

Galego ქართული

ქართული Deutsch

Deutsch Ελληνικά

Ελληνικά ગુજરાતી

ગુજરાતી Kreyol ayisyen

Kreyol ayisyen Harshen Hausa

Harshen Hausa Ōlelo Hawaiʻi

Ōlelo Hawaiʻi עִבְרִית

עִבְרִית हिन्दी

हिन्दी Hmong

Hmong Magyar

Magyar Íslenska

Íslenska Igbo

Igbo Bahasa Indonesia

Bahasa Indonesia Gaeilge

Gaeilge Italiano

Italiano 日本語

日本語 Basa Jawa

Basa Jawa ಕನ್ನಡ

ಕನ್ನಡ Қазақ тілі

Қазақ тілі ភាសាខ្មែរ

ភាសាខ្មែរ 한국어

한국어 كوردی

كوردی Кыргызча

Кыргызча ພາສາລາວ

ພາສາລາວ Latin

Latin Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba Lëtzebuergesch

Lëtzebuergesch Македонски јазик

Македонски јазик Malagasy

Malagasy Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം Maltese

Maltese Te Reo Māori

Te Reo Māori मराठी

मराठी Монгол

Монгол ဗမာစာ

ဗမာစာ नेपाली

नेपाली Norsk bokmål

Norsk bokmål پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português ਪੰਜਾਬੀ

ਪੰਜਾਬੀ Română

Română Русский

Русский Samoan

Samoan Gàidhlig

Gàidhlig Српски језик

Српски језик Sesotho

Sesotho Shona

Shona سنڌي

سنڌي සිංහල

සිංහල Slovenčina

Slovenčina Slovenščina

Slovenščina Afsoomaali

Afsoomaali Español

Español Basa Sunda

Basa Sunda Kiswahili

Kiswahili Svenska

Svenska Тоҷикӣ

Тоҷикӣ தமிழ்

தமிழ் తెలుగు

తెలుగు ไทย

ไทย Türkçe

Türkçe Українська

Українська اردو

اردو O‘zbekcha

O‘zbekcha Tiếng Việt

Tiếng Việt Cymraeg

Cymraeg isiXhosa

isiXhosa יידיש

יידיש Yorùbá

Yorùbá Zulu

Zulu