What Makes SMT Circuit Boards Superior to Through-Hole Technology?

The field of electronics manufacturing has experienced noteworthy advancement over the decades, with two overwhelming technologies forming the assembly of printed circuit boards (PCBs): Surface Mount Technology (SMT) and Through-Hole Technology (THT). Among these, SMT circuit boards have picked up noticeable quality for their prevalent execution, cost-efficiency, and flexibility. This article investigates the points of interest of SMT circuit boards and clarifies why they outperform through-hole Technology in different aspects.

What is an SMT Circuit Board?

An SMT circuit board is a sort of PCB that employments Surface Mount Technology for mounting electronic components. Not at all like through-hole Technology, which requires boring gaps into the board to embed component leads, SMT includes straightforwardly setting components on the surface of the PCB. The components, called surface-mount devices (SMDs), are patched onto the board utilizing mechanized machines, making the handle speedier and more efficient.

Key Focal points of SMT Circuit Boards Over Through-Hole Technology

1. Miniaturization and Compact Design

One of the most noteworthy preferences of SMT circuit boards is their capacity to oblige compact plans. Surface mount components are littler and lighter than their through-hole partners, permitting for higher component thickness. This miniaturization is pivotal for present day electronic electronics, such as savvy phones, tablets, and wearable contraptions, where space is at a premium.

Through-hole Technology, on the other hand, is restricted in its capacity to accomplish such compact plans due to the bigger estimate of components and the require for penetrated gaps. SMT circuit boards empower producers to pack more usefulness into littler impressions, a basic figure in today’s competitive electronics market.

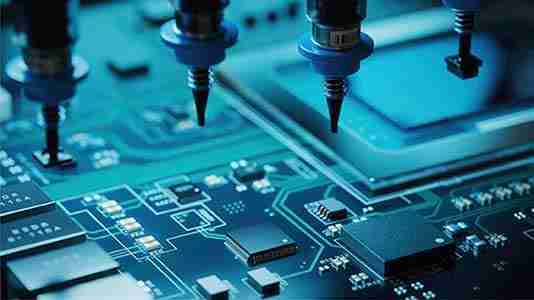

2. Higher Assembly Speeds

The assembly prepare for SMT circuit boards is profoundly computerized, coming about in altogether speedier generation times. Computerized pick-and-place machines can absolutely position thousands of components per hour, decreasing work costs and minimizing human blunder. In differentiate, through-hole get together regularly requires manual mediation, particularly for patching, which moderates down the prepare and increments costs.

This speed advantage makes SMT the favoured choice for high-volume generation runs, where productivity and adaptability are key priorities.

3. Improved Execution in High-Frequency Applications

SMT circuit boards exceed expectations in high-frequency and high-speed applications due to their shorter flag ways and lower parasitic inductance. The compact nature of surface-mount components decreases resistance and capacitance, upgrading the in general electrical execution of the PCB. These characteristics are basic for applications such as broadcast communications, aviation, and high-speed computing.

In differentiate, through-hole components have longer lead lengths, which can present commotion and flag debasement, making them less appropriate for high-frequency circuits.

4. Reduced Fabric Costs

The littler measure of surface-mount components interprets to lower fabric costs. SMT circuit boards require less crude materials, such as copper and PCB substrate, to accomplish the same usefulness as through-hole boards. Moreover, the nonappearance of bored gaps decreases manufacturing costs further.

Manufacturers can accomplish fetched reserve funds without compromising on execution, making SMT circuit boards an alluring alternative for both high-end and budget-friendly electronic products.

5. Enhanced Plan Flexibility

SMT circuit boards offer more noteworthy plan adaptability, empowering engineers to make more complex and multifunctional electronics. Since components can be mounted on both sides of the PCB, originators have more room to work with, permitting for inventive and proficient formats. This adaptability is especially useful in applications where space and weight limitations are basic, such as therapeutic electronics and car electronics.

Through-hole Technology, by comparison, limits plan conceivable outcomes due to its dependence on bored gaps and bigger components.

6. Improved Warm Performance

Surface-mount components are more proficient at scattering warm compared to through-hole components. The near vicinity of components on SMT circuit boards encourages superior warm administration, guaranteeing dependable execution beneath shifting working conditions. Heat-sensitive applications, such as control electronics and Driven lighting, advantage altogether from this advantage.

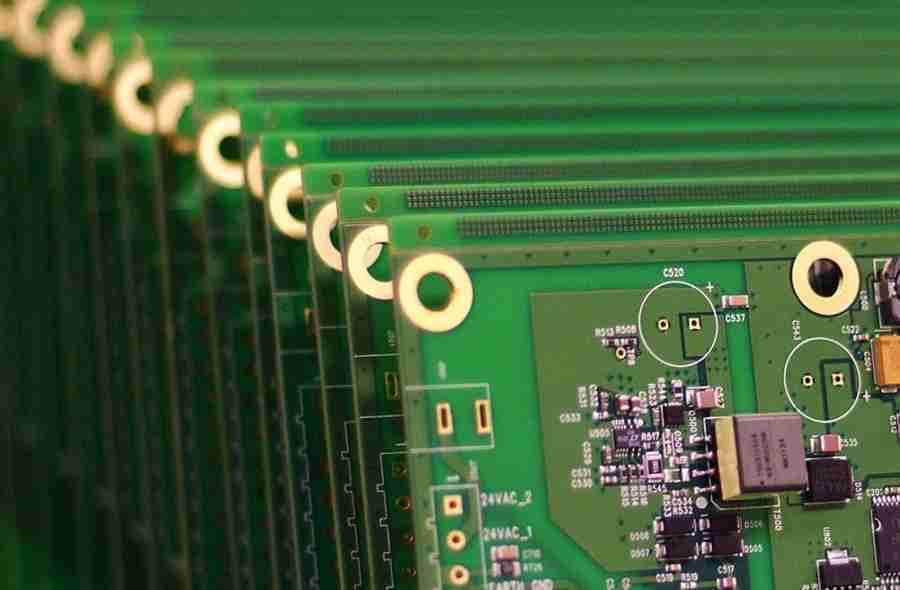

7. Reliability and Durability

SMT circuit boards are known for their unwavering quality and toughness, especially in situations subject to vibration or mechanical push. The patch joints in SMT boards are littler and more strong, diminishing the probability of disappointment. This makes them perfect for applications in car, aviation, and mechanical apparatus, where strength is non-negotiable.

Through-hole Technology, whereas advertising solid mechanical bonds, is more vulnerable to vibration-related issues due to the projecting leads of components.

8. Compatibility with Progressed Technologies

SMT circuit boards are superior suited for coordination progressed advances, such as chip, sensors, and remote communication modules. These components are ordinarily outlined for surface-mount applications, making SMT the default choice for cutting-edge electronic electronics. Through-hole Technology battles to keep up with these headways due to its measure and plan limitations.

Use Cases of SMT Circuit Boards

SMT circuit boards are utilized over a wide extend of businesses, much appreciated to their flexibility and predominant execution. A few common applications include:

• Consumer Hardware: Smartphone, tablets, keen observes, and domestic appliances.

• Automotive: Motor control units (ECUs), infotainment frameworks, and progressed driver-assistance frameworks (ADAS).

• Medical Electronics: Convenient demonstrative hardware, wearable wellbeing screens, and implantable devices.

• Telecommunications: Organize switches, partisan communication frameworks, and 5G infrastructure.

• Industrial Computerization: Mechanical autonomy, control frameworks, and IoT devices.

Challenges and Impediments of SMT Circuit Boards

Despite their various focal points, SMT circuit boards are not without challenges. A few of the key confinements include:

1. Complex Repair and Rework

The little estimate of surface-mount components makes them troublesome to repair or supplant. Specialized gear and skill are frequently required for revamp, which can increment support costs.

2. Initial Investment

Setting up an SMT generation line requires a critical forthright venture in apparatus and gear. In any case, the long-term fetched reserve funds and effectiveness picks up frequently exceed this introductory expense.

3. Limited Control Handling

Through-hole Technology is still favoured for applications requiring tall control taking care of, such as huge transformers and control supplies. SMT circuit boards may not be appropriate for these particular utilize cases due to their constrained current-carrying capacity.

Conclusion

SMT circuit boards have revolutionized the hardware industry by advertising unparalleled points of interest in terms of estimate, execution, and cost-efficiency. Their capacity to bolster miniaturization, high-frequency applications, and progressed advances makes them predominant to through-hole Technology in most scenarios. Whereas through-hole Technology still has its put in particular applications, the dominance of SMT circuit boards is apparent in today’s fast-paced, Technology-driven market.

By choosing SMT circuit boards, producers can make high-quality, dependable, and cutting-edge electronic items that meet the requests of advanced buyers. As Technology proceeds to progress, the part of SMT in forming the future of electronics will as it were ended up more unmistakable.

Latest Blog

Table of Content

Contcat Us

Phone: +86-18123905375

Email: sales@circuitcardassembly.com

Skype: ali_youte

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Afrikaans

Afrikaans Shqip

Shqip አማርኛ

አማርኛ العربية

العربية Հայերեն

Հայերեն Azərbaycan dili

Azərbaycan dili Euskara

Euskara Беларуская мова

Беларуская мова বাংলা

বাংলা Bosanski

Bosanski Български

Български Català

Català Cebuano

Cebuano Chichewa

Chichewa 简体中文

简体中文 繁體中文

繁體中文 Corsu

Corsu Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Esperanto

Esperanto Eesti

Eesti Filipino

Filipino Suomi

Suomi Français

Français Frysk

Frysk Galego

Galego ქართული

ქართული Deutsch

Deutsch Ελληνικά

Ελληνικά ગુજરાતી

ગુજરાતી Kreyol ayisyen

Kreyol ayisyen Harshen Hausa

Harshen Hausa Ōlelo Hawaiʻi

Ōlelo Hawaiʻi עִבְרִית

עִבְרִית हिन्दी

हिन्दी Hmong

Hmong Magyar

Magyar Íslenska

Íslenska Igbo

Igbo Bahasa Indonesia

Bahasa Indonesia Gaeilge

Gaeilge Italiano

Italiano 日本語

日本語 Basa Jawa

Basa Jawa ಕನ್ನಡ

ಕನ್ನಡ Қазақ тілі

Қазақ тілі ភាសាខ្មែរ

ភាសាខ្មែរ 한국어

한국어 كوردی

كوردی Кыргызча

Кыргызча ພາສາລາວ

ພາສາລາວ Latin

Latin Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba Lëtzebuergesch

Lëtzebuergesch Македонски јазик

Македонски јазик Malagasy

Malagasy Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം Maltese

Maltese Te Reo Māori

Te Reo Māori मराठी

मराठी Монгол

Монгол ဗမာစာ

ဗမာစာ नेपाली

नेपाली Norsk bokmål

Norsk bokmål پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português ਪੰਜਾਬੀ

ਪੰਜਾਬੀ Română

Română Русский

Русский Samoan

Samoan Gàidhlig

Gàidhlig Српски језик

Српски језик Sesotho

Sesotho Shona

Shona سنڌي

سنڌي සිංහල

සිංහල Slovenčina

Slovenčina Slovenščina

Slovenščina Afsoomaali

Afsoomaali Español

Español Basa Sunda

Basa Sunda Kiswahili

Kiswahili Svenska

Svenska Тоҷикӣ

Тоҷикӣ தமிழ்

தமிழ் తెలుగు

తెలుగు ไทย

ไทย Türkçe

Türkçe Українська

Українська اردو

اردو O‘zbekcha

O‘zbekcha Tiếng Việt

Tiếng Việt Cymraeg

Cymraeg isiXhosa

isiXhosa יידיש

יידיש Yorùbá

Yorùbá Zulu

Zulu