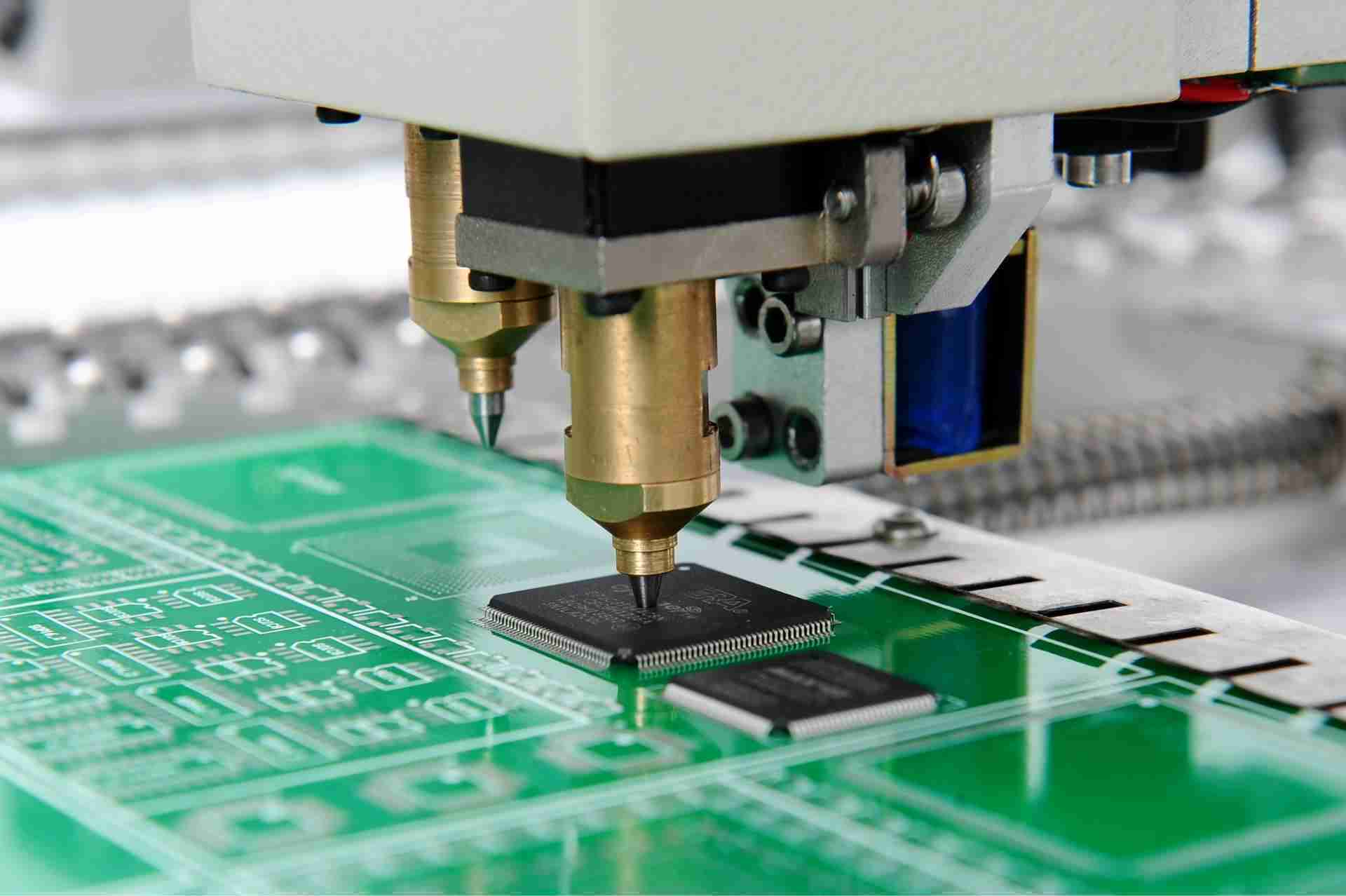

SMT is a crucial step in the PCB assembly process of PCBA factories, and it is also one of the necessary methods for quick turn PCB assembly. Therefore, PCB assemblers should follow the corresponding procedures during surface mount technology patching to avoid problems during patching. We have talked about SMT process specifications and common anomalies before. So, what problems usually occur during PCB SMT assembly?

1. Material throwing problem

Material throwing is one of the most common problems in SMT manufacturing processing.

The primary manifestation is that the nozzle cannot pick up components, or the picked-up components are not mounted on the PCB.

There are two main reasons for the problem of throwing materials:

1) Poor absorption

The reasons for poor suction include nozzle blockage, uneven nozzle surface, incorrect feeder position, erroneous component thickness set in the program, unreasonable picking height setting in the pick and place machine, etc.

2) Poor identification

The reasons for poor recognition include foreign matter and dust on the nozzle surface, dirt or scratches on the reflective surface of the nozzle, contamination on the glass cover and lens of the component recognition camera, etc.

2. Wrong item problem

Wrong parts are one of the most serious problems in the SMT mount technology patch processing and production process. Once wrong parts occur, the product will be scrapped and cause heavy economic losses.

There are several main reasons for the occurrence of wrong parts:

1) The tray information is wrong

When the operator replaces the material tray, if the material tray information is inconsistent with the material number of the station in the system, it will cause wrong parts.

2) Feed tray contamination

If other components remain on the tray, it may cause the wrong part.

3) Human operation errors

When replacing the tray, if the operator is not careful, it may cause the wrong part.

3. Flying pieces problem

The flying parts problem refers to the components picked up by the nozzle falling off during the SMT assembly process.

There are several main reasons for the problem of flying parts:

1) The nozzle is clogged, or the surface is uneven

If the nozzle is clogged or the surface is uneven, it will affect the fit between the nozzle and the component, resulting in flying parts.

2) Components are defective or do not meet standards

If the components are defective or do not meet the standards, it will also result in flying parts. So, the choice of PCB component suppliers also is significant.

3) Support pin height is inconsistent

If the support pin heights are inconsistent, the PCB board will not be able to remain level, resulting in flying parts.

4) The component thickness is incorrectly set in the program

If the program sets the wrong component thickness, the patch height will be unreasonable, resulting in flying parts.

5) The patch pressure is too high

If the patch pressure is too high, it may cause the component to fly off.

6) Insufficient solder paste viscosity

If the solder paste is not sticky enough, the components may fall off during the transfer of the PCB board.

Summarize

Common problems in PCB SMT assembly will affect printed circuit quality and manufacturing efficiency. Therefore, printed circuit manufacturers should strengthen the prevention and control of these problems during the SMT production process.

Specific measures include:

Do a good job of maintaining and servicing the equipment to prevent failure.

Strictly follow the procedures to avoid human operating errors.

Strengthen quality inspection of components to prevent wrong and missing parts.

Taking the above measures can effectively reduce problems in SMT patch manufacturing. And it can improve the quality and production efficiency of circuit boards.