Why PCB Assembly Manufacturing is Crucial for High-Quality Electronics Production?

Printed Circuit Boards (PCBs) are the spine of present day gadgets. They shape the establishment upon which all electronic components are mounted and interconnected, empowering the usefulness and execution of the gadgets we depend on day by day. PCB Assembly Manufacturing is the prepare of joining these components into PCBs, guaranteeing that the conclusion item meets both utilitarian and quality guidelines. In this Content, we’ll dive into the basic part of PCB assembly and manufacturing, focusing on its affect on high-quality electronics production.

The Core of Electronics: PCB Assembly and Manufacturing

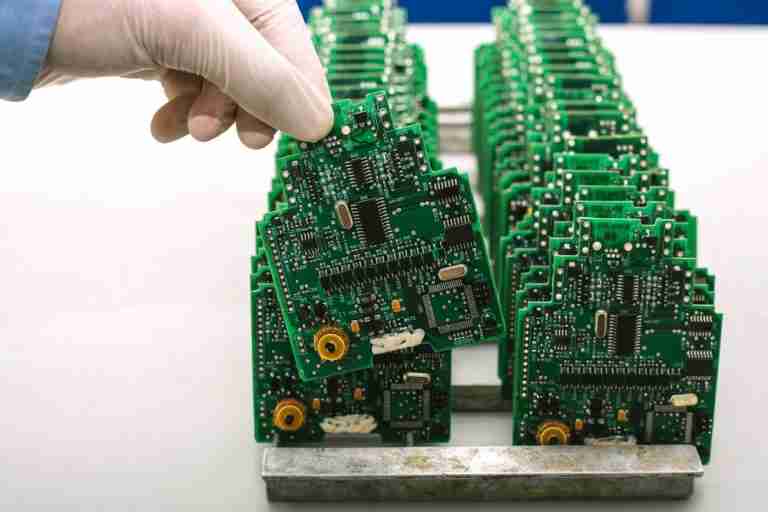

PCB assembly manufacturing includes setting and fastening electronic components onto the uncovered PCB to make a working circuit. The combination of PCB manufacturing and assembly makes items that control an broad run of businesses, counting customer gadgets, car, healthcare, aviation, and telecommunications.

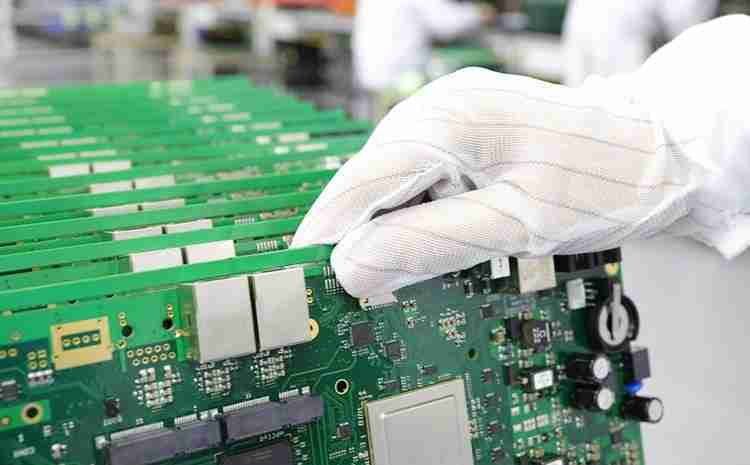

Modern electronic gadgets request compact plans, expanded usefulness, and tall unwavering quality. Accomplishing these requires exactness and ability in PCB assembly and manufacturing forms. A well-executed PCB manufacturing assembly prepare guarantees vigorous associations, productive component situation, and adherence to the exacting necessities of complex electronic systems.

Importance of PCB Manufacturing in High-Quality Electronics

1. Establishment for Reliability

The unwavering quality of an electronic gadget starts with the PCB. High-quality PCB assembly manufacturing forms guarantee that the establishment is solid, with precise layer arrangements, well-aligned components, and secure patch joints. This unwavering quality minimizes the hazard of gadget disappointment, guaranteeing life span and steady performance.

2. Progressed Technology Integration

As gadgets gotten to be more astute and more capable, PCBs require to bolster progressed highlights like IoT network, AI capabilities, and high-speed information preparing. PCB manufacturing assembly forms play a significant part in coordination these cutting-edge advances, empowering proficient gadget operation without compromising reliability.

3. Cost-Effective Production

Precision in PCB assembly manufacturing diminishes wastage, minimizes blunders, and guarantees productive utilize of materials. By embracing progressed assembly strategies, producers can scale generation and keep up fetched effectiveness, straightforwardly profiting businesses and consumers.

Key Forms in PCB Assembly Manufacturing

To get it its significance, it’s pivotal to break down the forms included in PCB manufacturing assembly:

1. Plan and Prototyping

Every effective electronic item begins with a point by point PCB plan. Utilizing computer-aided design (CAD) computer program, engineers make exact formats that characterize the board’s electrical pathways. Prototyping takes after, permitting producers to test the plan some time recently full-scale production.

2. Component Sourcing

Selecting high-quality components is crucial for solid PCB assembly. Producers must source components that meet the required details, guaranteeing compatibility and performance.

3. Surface Mount Technology (SMT)

SMT is the most common strategy for amassing components on a PCB. It includes mounting components specifically onto the surface of the board. Progressed apparatus places components with extraordinary exactness, guaranteeing ideal execution and compact designs.

4. Through-Hole Technology (THT)

THT is another strategy of assembly where components are embedded into pre-drilled gaps on the PCB. This strategy is frequently utilized for components that require solid mechanical bonds, such as connectors.

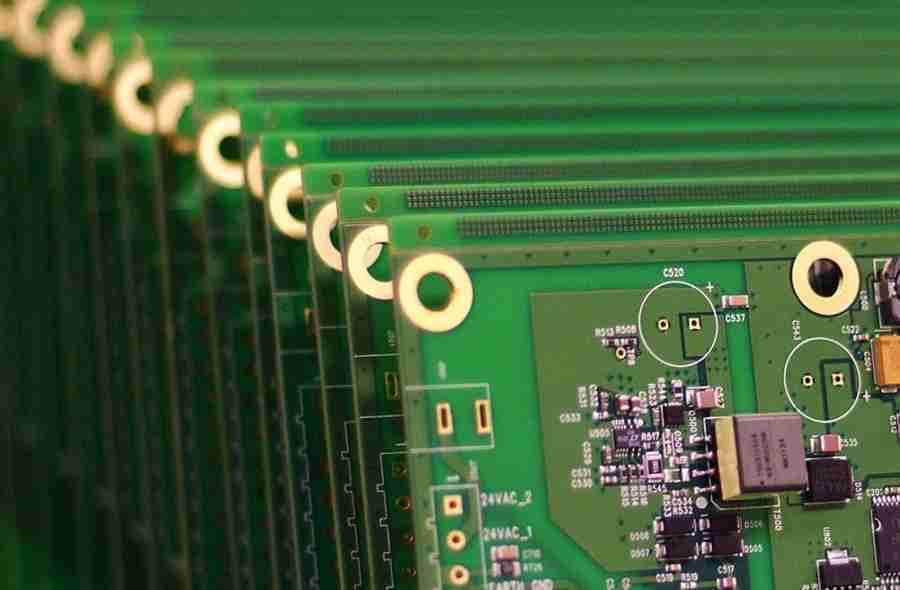

5. Soldering and Inspection

The patching handle secures components to the PCB, with procedures like wave fastening or reflow fastening depending on the assembly strategy. Post-soldering reviews, counting automated optical inspection (AOI) and X-ray assessments, guarantee all joints are defect-free.

6. Testing and Quality Assurance

Functional testing is an fundamentally portion of PCB assembly manufacturing. It approves that the last item performs as expecting beneath different conditions. Thorough quality control conventions avoid flawed units from coming to customers, securing brand notoriety and client satisfaction.

Why High-Quality PCB Manufacturing Assembly Matters

1. Upgraded Item Performance

The quality of PCB assembly specifically influences the execution of the last item. A high-quality PCB guarantees ideal flag astuteness, control conveyance, and warm administration, all of which are basic for requesting applications like aviation or restorative devices.

2. Versatility in Production

As request for electronic items develops, producers must scale operations whereas keeping up quality. PCB manufacturing assembly forms utilize robotization and effective workflows, empowering reliable quality in high-volume production.

3. Versatility to Rising Trends

Technology advances quickly, presenting unused challenges like miniaturization and complex circuitry. PCB assembly manufacturing meets these challenges by receiving progressed procedures such as multi-layer PCBs, adaptable PCBs, and microelectronics integration.

Applications Over Industries

1. Consumer Electronics

From smart phones and portable workstations to savvy domestic gadgets, customer electronics require exact PCB manufacturing assembly forms to guarantee usefulness and durability.

2. Automotive

The car industry depends on PCBs for applications like motor administration, route frameworks, and electric vehicle Technology. These PCBs must persevere cruel conditions, making high-quality assembly essential.

3. Therapeutic Devices

In the healthcare segment, gadgets like pacemakers, imaging electronics, and demonstrative devices request faultless PCB execution. Mistakes in assembly can jeopardize lives, underscoring the require for exacting quality standards.

4. Aviation and Defense

Aerospace and defense gadgets confront extraordinary situations and thorough execution necessities. PCB assembly manufacturing guarantees that these basic frameworks are solid and fail-proof.

The Part of Progressed Technologys in PCB Assembly Manufacturing

Innovative Technologies have changed PCB manufacturing assembly forms, empowering more noteworthy exactness, effectiveness, and capabilities:

1. Automation and Robotics

Automation makes strides assembly exactness and diminishes generation times. Mechanical frameworks can put components with micro-level exactness, guaranteeing negligible errors.

2. 3D Printing

3D printing Technology helps in fast prototyping, permitting engineers to test plans rapidly and make vital alterations some time recently mass production.

3. Artificial Intelligence (AI)

AI-powered frameworks optimize manufacturing workflows, improve quality reviews, and foresee potential abandons. This proactive approach anticipates exorbitant mistakes and downtime.

4. Progressed Materials

Innovative materials, such as high-frequency covers and adaptable substrates, back progressed applications. PCB assembly forms adjust to handle these materials efficiently.

Challenges in PCB Assembly Manufacturing

Despite its preferences, PCB manufacturing assembly comes with challenges:

1. Component Availability

Global supply chain disturbances can affect the accessibility of basic components, driving to delays and expanded costs.

2. Plan Complexity

Miniaturization and multi-layer plans increment assembly complexity, requiring progressed methods and talented personnel.

3. Exacting Quality Standards

Industries like aviation and healthcare force thorough benchmarks, making quality confirmation a resource-intensive process.

4. Environmental Regulations

Manufacturers must comply with natural guidelines, such as RoHS (Restriction of Hazardous Substances), which manage fabric utilization and transfer practices.

Conclusion

PCB assembly manufacturing is at the heart of high-quality electronics generation. From guaranteeing unwavering quality and adaptability to joining progressed advances, this handle is basic to conveying the inventive electronic gadgets that drive present day life. By prioritizing exactness, effectiveness, and quality, PCB manufacturing assembly empowers the creation of items that meet the ever-evolving requests of buyers and businesses alike.

As Technology progresses, so will the strategies and materials utilized in PCB assembly manufacturing, pushing the boundaries of what’s conceivable in electronic plan and usefulness. By grasping these advancements and tending to challenges, producers will proceed to play a crucial part in forming the future of gadgets.

Latest Blog

Table of Content

Contcat Us

Phone: +86-18123905375

Email: sales@circuitcardassembly.com

Skype: ali_youte

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Afrikaans

Afrikaans Shqip

Shqip አማርኛ

አማርኛ العربية

العربية Հայերեն

Հայերեն Azərbaycan dili

Azərbaycan dili Euskara

Euskara Беларуская мова

Беларуская мова বাংলা

বাংলা Bosanski

Bosanski Български

Български Català

Català Cebuano

Cebuano Chichewa

Chichewa 简体中文

简体中文 繁體中文

繁體中文 Corsu

Corsu Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Esperanto

Esperanto Eesti

Eesti Filipino

Filipino Suomi

Suomi Français

Français Frysk

Frysk Galego

Galego ქართული

ქართული Deutsch

Deutsch Ελληνικά

Ελληνικά ગુજરાતી

ગુજરાતી Kreyol ayisyen

Kreyol ayisyen Harshen Hausa

Harshen Hausa Ōlelo Hawaiʻi

Ōlelo Hawaiʻi עִבְרִית

עִבְרִית हिन्दी

हिन्दी Hmong

Hmong Magyar

Magyar Íslenska

Íslenska Igbo

Igbo Bahasa Indonesia

Bahasa Indonesia Gaeilge

Gaeilge Italiano

Italiano 日本語

日本語 Basa Jawa

Basa Jawa ಕನ್ನಡ

ಕನ್ನಡ Қазақ тілі

Қазақ тілі ភាសាខ្មែរ

ភាសាខ្មែរ 한국어

한국어 كوردی

كوردی Кыргызча

Кыргызча ພາສາລາວ

ພາສາລາວ Latin

Latin Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba Lëtzebuergesch

Lëtzebuergesch Македонски јазик

Македонски јазик Malagasy

Malagasy Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം Maltese

Maltese Te Reo Māori

Te Reo Māori मराठी

मराठी Монгол

Монгол ဗမာစာ

ဗမာစာ नेपाली

नेपाली Norsk bokmål

Norsk bokmål پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português ਪੰਜਾਬੀ

ਪੰਜਾਬੀ Română

Română Русский

Русский Samoan

Samoan Gàidhlig

Gàidhlig Српски језик

Српски језик Sesotho

Sesotho Shona

Shona سنڌي

سنڌي සිංහල

සිංහල Slovenčina

Slovenčina Slovenščina

Slovenščina Afsoomaali

Afsoomaali Español

Español Basa Sunda

Basa Sunda Kiswahili

Kiswahili Svenska

Svenska Тоҷикӣ

Тоҷикӣ தமிழ்

தமிழ் తెలుగు

తెలుగు ไทย

ไทย Türkçe

Türkçe Українська

Українська اردو

اردو O‘zbekcha

O‘zbekcha Tiếng Việt

Tiếng Việt Cymraeg

Cymraeg isiXhosa

isiXhosa יידיש

יידיש Yorùbá

Yorùbá Zulu

Zulu