The fast advancement of hardware has altogether changed businesses and day by day life, from consumer Electronics to medical devices, automotive technology, and past. At the heart of these advancements lies a crucial component: the PCB (Printed Circuit Board). It serves as the spine of electronic Electronics, giving auxiliary back and electrical associations that control everything from smart phones to satellites. The design of PCB circuit boards is vital in pushing the boundaries of what is conceivable in hardware, guaranteeing proficiency, execution, and unwavering quality. This Content dives into why PCB circuit board design is so basic for Electronics development and how PCB manufacturers and PCB board makers play a key part in forming the future of technology.

What is PCB Circuit Board Design?

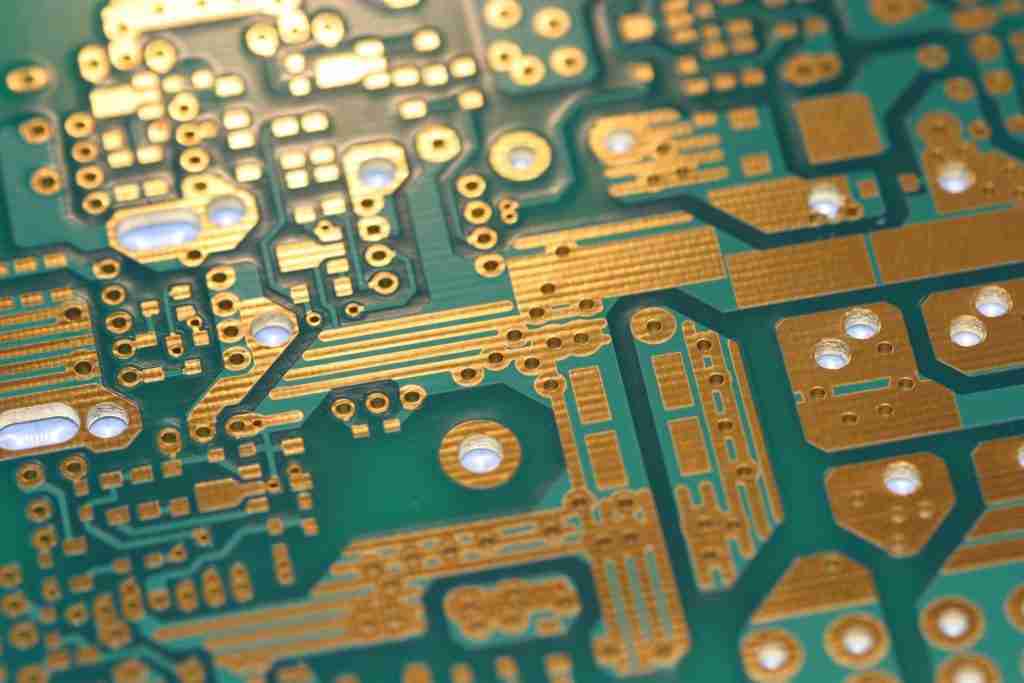

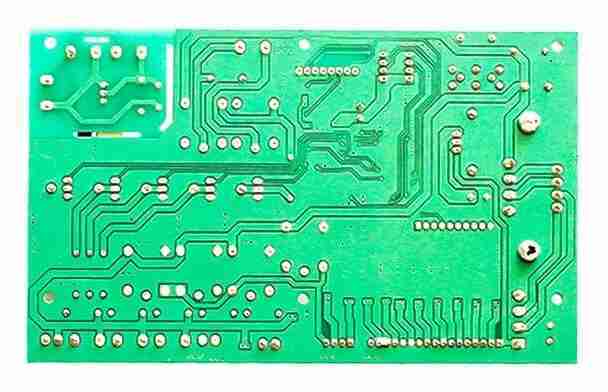

A PCB circuit board design alludes to the format of the conductive pathways and components on a printed circuit board that are vital for an electronic gadget to work. It includes designing the physical, electrical, and mechanical structure of the board, guaranteeing that all components are appropriately situated and interconnected for the gadget to work ideally. The design must consider components such as the electrical characteristics of the components, warm administration, flag judgment, and control distribution.

PCB design is both an craftsmanship and a science, requiring a profound understanding of hardware and building standards. It is a complex prepare that requests cautious arranging, testing, and prototyping to make a useful and solid item. The design handle is ordinarily upheld by specialized computer program instruments that offer assistance engineers to visualize and optimize the format some time recently generation begins.

Why PCB Circuit Board Design is Pivotal for Electronics Innovation

1. Foundation for Gadget Functionality

A PCB circuit board design is the heart of any electronic gadget. It serves as the stage that interfaces and underpins the different electronic components, such as microchips, resistors, capacitors, and sensors, empowering them to work together as a cohesive unit. Without a well-designed PCB, the components would not be able to communicate or perform their expecting capacities, driving to breakdown or disappointment of the device.

Innovations in Electronics frequently depend on the improvement of more progressed components and frameworks that require specialized PCB designs to work effectively. For case, cutting-edge innovations such as 5G communication, fake insights, and independent vehicles depend on exceedingly complex and exact PCB circuit board designs to guarantee their components perform at their peak.

2. Miniaturization of Electronics

As request for littler, lighter, and more compact electronic Electronics develops, PCB circuit board design plays an progressively critical part in accomplishing miniaturization. Present day Electronics, from wearable tech to smart phones and rambles, require to be both lightweight and effective, which presents a challenge for PCB originators. They must make complex formats that maximize space utilization whereas guaranteeing solid electrical connections.

Miniaturized PCBs regularly consolidate progressed methods such as multi-layer designs, where a few layers of circuitry are stacked on beat of each other. This permits for more components to be pressed into a littler region, contributing to the by and large estimate diminishment of the gadget. Accomplishing this level of miniaturization requires adroit PCB design and the utilize of progressed Manufacturing forms that can deliver high-density, high-performance circuit boards.

3. Improved Execution and Efficiency

The design of the PCB circuit board specifically impacts the execution of the electronic gadget. A well-optimized PCB can progress flag judgment, minimize commotion, and decrease electromagnetic interference (EMI), all of which are basic for the smooth operation of high-speed circuits and Electronics. For illustration, in applications like high-frequency communication frameworks, therapeutic gear, and aviation innovation, indeed a little design blemish can have noteworthy results on execution and reliability.

Additionally, control dispersion is a significant perspective of PCB design. Ineffectively designed PCBs can lead to control misfortunes, intemperate warm era, and decreased battery life in versatile Electronics. On the other hand, a well-designed PCB guarantees that control is conveyed effectively over the board, decreasing warm era and dragging out the life of the device.

4. Customization for Specialized Applications

As electronic Electronics ended up more specialized to meet the needs of particular businesses or applications, the request for customized PCB designs is developing. For occurrence, in the car industry, PCB circuit board designs must be able to withstand unforgiving situations, counting extraordinary temperatures and vibrations. Essentially, therapeutic Electronics require PCBs with extraordinary unwavering quality and biocompatibility.

Customization includes fitting the PCB circuit board design to meet the particular necessities of the application, whether it be guaranteeing the board’s capacity to handle tall voltages, coordination sensors for information collection, or assembly administrative guidelines for security and execution. This level of customization empowers the advancement of cutting-edge advances that can address special challenges over different industries.

5. Cost-Effectiveness and Scalability

While PCB circuit board design is a pivotal portion of hardware development, it must too consider cost-effectiveness, particularly in large-scale generation. A well-designed PCB can decrease Manufacturing costs by minimizing fabric squander, streamlining get together forms, and improving the in general effectiveness of the generation line. Productive design hones, such as decreasing the number of components or optimizing the format, can lead to critical taken a toll reserve funds in mass production.

Scalability is another key figure. Once the PCB design is finalized, it must be versatile to meet the requests of huge generation runs. The design needs to guarantee that it can be proficiently fabricated in expansive amounts without compromising quality or execution. This is where PCB manufacturers and PCB board manufacturers play a basic part, guaranteeing that the design can be reproduced precisely and consistently.

6. Advancement in Manufacturing Technologies

As PCB manufacturers embrace modern innovations, such as computerized gathering forms, 3D printing, and progressed materials, the conceivable outcomes for advancement in PCB circuit board design grow essentially. These advances permit for more complex designs, higher accuracy, and speedier generation times, all of which are fundamental for assembly the ever-growing request for progressed electronic products.

For case, 3D printing has made it conceivable to make multi-dimensional PCBs with complex geometries that were already troublesome to accomplish utilizing conventional Manufacturing strategies. This development opens up modern roads for PCB architects, permitting them to investigate novel designs that can move forward the execution and usefulness of electronic devices.

7. Reliability and Durability

Reliability and strength are vital in numerous businesses, especially in segments such as aviation, defense, and therapeutic Electronics. A PCB circuit board design must account for variables like temperature changes, mechanical push, and natural introduction, guaranteeing that the board will work reliably over time without failure.

A well-designed PCB can upgrade the strength of the gadget by giving strong associations and avoiding issues like flag debasement or component harm. This is vital for businesses where disappointment is not an choice, and Electronics must work beneath extraordinary conditions. For occurrence, PCB manufacturers that specialize in high-reliability designs, such as military-grade PCBs, get it the significance of guaranteeing that their designs can withstand the most requesting environments.

8. Faster Time to Market

In today’s competitive hardware scene, getting items to showcase rapidly is basic for remaining ahead of the competition. A well-thought-out PCB circuit board design can altogether diminish improvement time by minimizing the require for expensive and time-consuming updates. By utilizing re-enactment apparatuses and models, makers can test their designs some time recently committing to full-scale generation, guaranteeing that potential issues are tended to early on.

Moreover, collaboration between PCB board makers and architects is vital in assisting the prepare. Near communication guarantees that the design is manufacturable and that potential challenges can be tended to at the design arrange, driving to quicker turnaround times and speedier item launches.

The Part of PCB Manufacturers and PCB Board Makers

PCB manufacturers and PCB board makers play an basic part in the victory of PCB circuit board design. They are capable for changing the design into a physical item that meets the required details. A gifted PCB producer guarantees that the boards are created with the most noteworthy quality benchmarks and that they perform dependably in their expecting applications.

PCB board makers too offer important skill in ranges like fabric choice, component sourcing, and get together forms. They work closely with originators to distinguish potential challenges and offer arrangements that can optimize both the design and the Manufacturing prepare. Their capacity to create high-quality, exactness PCBs at scale is crucial to supporting the fast-paced development cycle of the Electronics industry.

Conclusion

In conclusion, PCB circuit board design is a basic figure in driving the advance of Electronics development. Whether it’s empowering the miniaturization of Electronics, progressing execution, or permitting for customization to meet specialized needs, the design of the PCB shapes the establishment for the usefulness and unwavering quality of electronic Electronics. As electronic innovation proceeds to advance, the part of gifted PCB architects, along with master PCB manufacturers and PCB board manufacturers, will gotten to be indeed more critical in guaranteeing the victory of cutting-edge items. By pushing the boundaries of PCB design, the Electronics industry can proceed to advance and make groundbreaking advancements that shape the future.