Why Pinner Job is Highly Important in PCB Manufacturing?

What is PCB Pinner?

Accuracy and precision are paramount when it comes to PCBs. The PCB is the backbone of most electronic devices, be it a smart phone, computer, or restorative hardware and automobiles. A PCB Pinner is a specialized proficient who plays a crucial part in the early stages of the PCB manufacturing handle. This work is centred around guaranteeing that the components of a PCB are precisely situated and adjusted some time recently the fastening prepare starts. In spite of the fact that the term “Pinner” might not be as broadly known exterior the PCB industry, it is indispensably to the generation and quality affirmation of PCBs.

Definition of PCB Pinner

A PCB Pinner is capable for the physical assignment of putting or “pinning” the components, such as resistors, capacitors, and ICs (integrated circuits), onto a PCB board. This prepare regularly happens amid the gathering stage, fair some time recently the components are patched to the board. A PCB Pinner employments a run of apparatuses and methods to guarantee that each component is put with tall exactness, keeping up the rectify introduction and position as indicated by the PCB design.

There are two essential sorts of PCB pinning jobs:

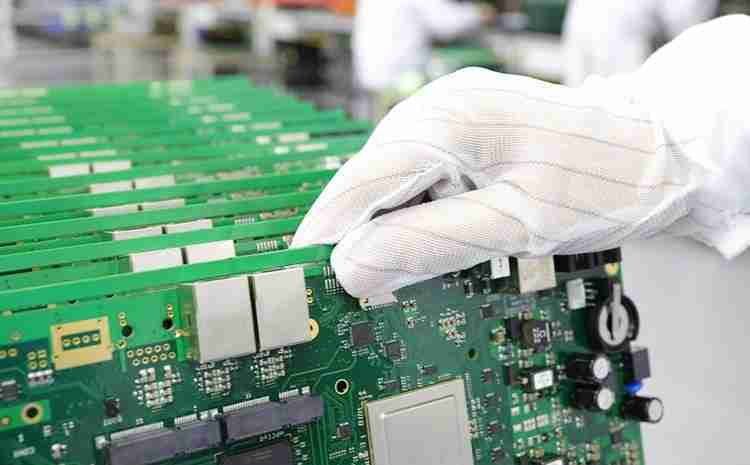

1. Manual Pinning: In smaller-scale or specialized PCB assembly operations, the Pinner physically positions each component on the board. This requires a sharp eye for detail and information of the particular components being used.

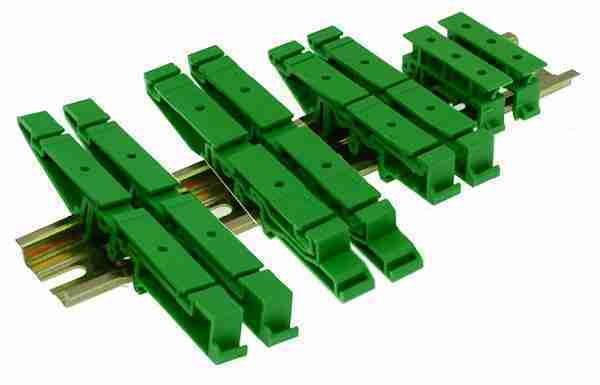

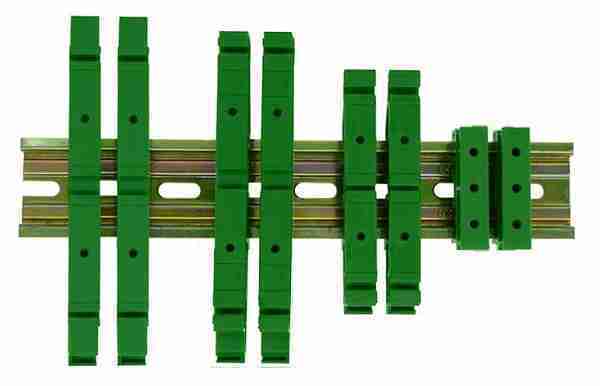

2. Automated Pinning: In bigger manufacturing plants, mechanized apparatus is frequently utilized to perform the pinning assignments. In any case, indeed with computerization, the part of a PCB Pinner is still basic for observing the hardware, guaranteeing the machines are working accurately, and supervising the exactness of the last result.

Regardless of whether the handle is manual or computerized, the PCB Pinner guarantees that the gathering is redress some time recently continuing to the following stages of generation, such as patching and testing.

The Part of a PCB Pinner in PCB Manufacturing

The PCB manufacturing handle includes numerous steps, from planning the circuit format to manufacturing the real board. Pinning is one of the most basic steps in the gathering stage. To get it why this part is so imperative, let’s break down the key perspectives of the PCB Pinner’s job:

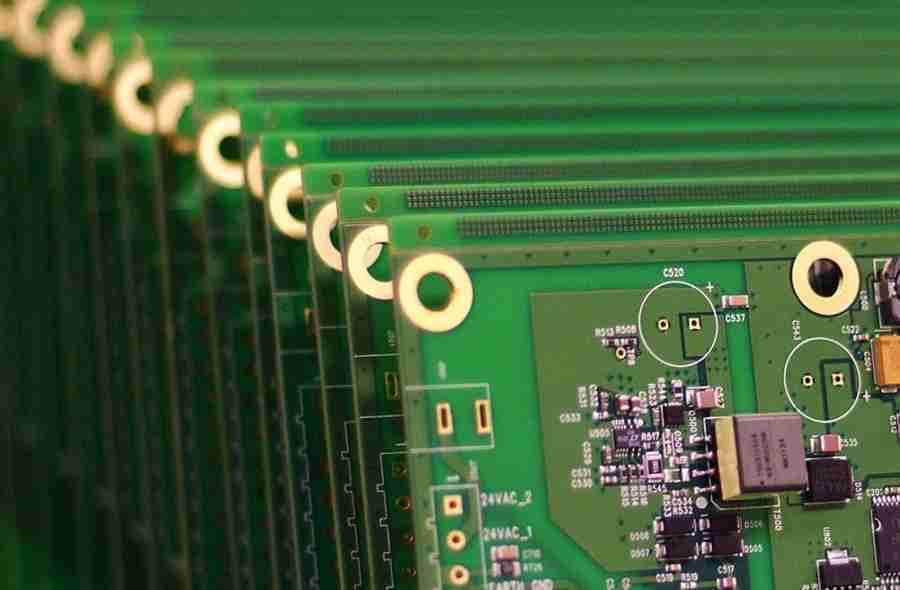

1. Component Arrangement and Precision: One of the essential obligations of the PCB Pinner is to guarantee that the electronic components are set accurately on the PCB. The plan records (such as Gerber records) give the format subtle elements of where each component ought to be put. Misalignment of indeed a single component can cause glitch or disappointment of the whole circuit. The PCB Pinner guarantees that each component, such as resistors, capacitors, and chips, is accurately situated some time recently fastening. This exactness is significant since, in cutting edge PCBs, the components are regularly amazingly little, with negligible tolerances.

2. Component Orientation: Another basic errand is guaranteeing that the components are arranged accurately. Numerous electronic components, particularly coordinates circuits (ICs), are polarized, meaning they must be embedded in the redress introduction to work legitimately. A PCB Pinner must be able to recognize these polarized components and guarantee that they are accurately adjusted with the board. Disappointment to situate components accurately may result in brief circuits or disappointment of the PCB to work as intended.

3. Quality Control and Assessment: The Pinner is regularly then to begin with line of defense when it comes to recognizing issues in the gathering prepare. They assess the PCB board for any abandons or misplacements in components. This may incorporate reviewing for bowed pins, misaligned components, or harmed parts. If an issue is identified, it is the obligation of the PCB Pinner to either alter the component situation or report the mistake to the pertinent professional. Catching these issues early in the prepare can spare time and cash in the long run by maintaining a strategic distance from the require for adjust or rejecting defective sheets later.

4. Interaction with Other Groups: A PCB Pinner works closely with other individuals of the PCB assembly group, counting fastening specialists, machine administrators, and quality control pros. Successful communication between group individuals is fundamental to guarantee the smooth stream of the generation prepare. For occurrence, if a Pinner takes note an issue with the format or component supply, they must caution the pertinent divisions to amend the issue some time recently continuing further.

5. Tool Capability: A PCB Pinner must be talented in utilizing a assortment of instruments, from basic tweezers and hand apparatuses to more complex machines and mechanical arrangement frameworks. For manual pinning, the Pinner employments exactness instruments to put the components carefully onto the board. In mechanized situations, the Pinner is capable for programming and keeping up the automated situation frameworks. Understanding the apparatus and apparatuses is basic for guaranteeing the work is done proficiently and without error.

Why Pinner Job is Highly Vital in PCB Manufacturing Companies?

Now that we have an understanding of what a PCB Pinner does, let’s investigate why this part is so basic in PCB manufacturing companies.

1. Guaranteeing Item Quality

The quality of a PCB specifically impacts the execution and unwavering quality of the conclusion item, whether it’s a buyer contraption or a complex mechanical framework. If components are misaligned or inaccurately set amid the gathering prepare, the whole usefulness of the circuit can be compromised. In numerous cases, these mistakes may not be promptly obvious, making the Pinner’s part indeed more significant. The work requests exactness and cautious consideration to detail, which is basic to guaranteeing that each PCB meets the required quality standards.

In numerous businesses, such as aviation, therapeutic, and car, the results of a flawed PCB can be disastrous. Hence, the Pinner plays a imperative part in guaranteeing that the PCB capacities as planned, driving to higher-quality items that meet industry benchmarks and client expectations.

2. Maintaining a strategic distance from Expensive Errors

Incorrect arrangement of components on the PCB can lead to delays in generation and exorbitant mistakes that require adjust or rejecting of imperfect units. These blunders can cause noteworthy money related misfortune, particularly if they are found late in the generation cycle. Since the Pinner is one of the to begin with to spot potential issues, they offer assistance minimize the hazard of blunders coming to afterward stages of generation, where redressing these botches would be more time-consuming and costly. By precisely situating components in the early stages, the Pinner makes a difference diminish costs related with repairs, substitutions, and client dissatisfaction.

3. Encouraging Proficient Generation Workflow

The part of the PCB Pinner is indispensably to keeping up the proficiency of the whole PCB manufacturing handle. Appropriately stuck components are simpler to patch and test, streamlining the by and large workflow. If components are misaligned or inaccurately put, it can cause delays amid the fastening or review forms, driving to a excess and diminished efficiency. By performing their errand productively, the Pinner guarantees that the gathering line runs easily, minimizing bottlenecks and decreasing downtime.

4. Contributing to the Adaptability of PCB Manufacturing

As PCB manufacturing companies scale up generation to meet the developing request for hardware, the part of the Pinner gets to be indeed more vital. In high-volume generation settings, the edge for mistake is little, and speed is of the substance. An experienced PCB Pinner guarantees that components are put rapidly and accurately, making a difference the company keep up with generation requests. Also, mechanized pinning frameworks, which the Pinner makes a difference keep up and work, permit for mass generation without relinquishing exactness. This adaptability is basic for assembly the needs of worldwide markets.

5. Upgrading Client Satisfaction

Customers depend on PCB producers to create dependable, high-quality sheets. If a producer reliably conveys inadequate or subpar PCBs, they chance harming their notoriety and losing clients. The Pinner’s consideration to detail and capacity to guarantee the accuracy of each PCB makes a difference keep up the manufacturer’s notoriety for quality. Moreover, by guaranteeing that each board is built accurately from the begin, the Pinner plays an circuitous but basic part in client fulfilment. As a result, the company is more likely to meet due dates and satisfy orders with less issues, driving to more grounded client connections and rehash business.

6. Supporting Development and Item Development

The PCB manufacturing industry is exceedingly inventive, with modern plans and innovations developing all the time. The Pinner’s part is fundamental in guaranteeing that unused, complex PCBs are accurately gathered. With cutting-edge plans requiring exact component arrangement and progressed manufacturing strategies, a gifted PCB Pinner gets to be crucial in encouraging the generation of high-tech gadgets. Whether it’s creating wearable gadgets, independent vehicles, or progressed restorative gadgets, the Pinner’s work is a key enabler of development in the gadgets industry.

Key Aptitudes for a Pinner in PCB Factories

The part of a PCB Pinner is exceedingly specialized and requires a combination of specialized abilities, accuracy, and consideration to detail. A Pinner’s duties in a PCB plant are imperative to guaranteeing the effective assembly of printed circuit sheets (PCBs), which are the establishment of for all intents and purposes all advanced electronic gadgets. Underneath are the key aptitudes required for a Pinner in PCB factories:

1. Consideration to Detail

One of the most pivotal abilities for a PCB Pinner is consideration to detail. Since PCB components are regularly exceptionally little, exact situation is fundamental. Indeed a slight misalignment of a component can lead to usefulness issues, causing exorbitant mistakes or item disappointments. A Pinner must be able to fastidiously take after plan details and recognize any potential issues early in the process.

2. Manual Dexterity

Since a critical portion of the work may include manual situation of components, manual smoothness is fundamental. A Pinner ought to have unfaltering hands and the capacity to control little devices and components with exactness. Fine engine aptitudes are essential to handle modest components, such as resistors, capacitors, and coordinates circuits, without harming them or the PCB itself.

3. Information of PCB Plan Files

To precisely put components on a PCB, the Pinner must be commonplace with PCB plan records (e.g., Gerber records). These records contain nitty gritty data on the format, counting component areas, sizes, and electrical associations. A strong understanding of these plan records permits the Pinner to put components precisely agreeing to the building determinations, guaranteeing the last item matches the expecting design.

4. Understanding of Electronic Components

A Pinner must have an understanding of electronic components and their capacities. Nature with components such as capacitors, resistors, diodes, and coordinates circuits is vital, as the Pinner needs to distinguish each portion and guarantee it’s set accurately. Knowing the extremity and introduction of components like diodes and ICs is moreover vital to maintain a strategic distance from blunders. This information guarantees that the components are not as it were situated accurately but moreover situated legitimately for ideal performance.

5. Capability with Devices and Equipment

A PCB Pinner must be capable with a assortment of apparatuses and hardware, both manual and robotized. This incorporates utilizing hand apparatuses like tweezers, little pincers, and fastening irons, as well as working mechanized machines utilized in bigger industrial facilities for component situation. Understanding how to utilize and troubleshoot these instruments is basic, particularly when performing manual pinning or keeping up mechanized systems.

6. Soldering Knowledge

While the essential obligation of a Pinner is to put components on the PCB, fastening information is still critical. The Pinner regularly works closely with the patching group or may indeed require to do minor fastening themselves. Understanding the nuts and bolts of fastening, counting temperature control, patch glue, and flux application, is vital for guaranteeing that components are safely joined once they are placed.

7. Quality Control and Review Skills

Quality control is a crucial portion of a Pinner’s work. They must be able to assess each board for surrenders, such as misaligned or lost components, bowed pins, or other defects. Having a sharp eye for detail and utilizing quality control devices (e.g., amplifying glasses, magnifying instruments) guarantees that any issues are spotted some time recently the board continues to the patching or testing stages. Early location of surrenders decreases the probability of exorbitant adjust and item disappointment.

8. Time Management and Efficiency

In fast-paced production environments, time management is essential. The Pinner must work quickly and efficiently to keep up with production targets while maintaining accuracy. This requires good organizational skills to manage multiple tasks, prioritize their work, and minimize downtime between tasks.

9. Basic Computer Skills

While much of the work is hands-on, modern PCB factories may require Pinner to use basic computer software to track component placement or to interface with automated systems. Proficiency in using a computer for tasks such as reading PCB layout files, reporting production status, or operating machinery is important in today’s digitalized manufacturing environment. 12. Knowledge of Safety Protocols

Conclusion

A crucial figure in the PCB manufacturing process is the PCB Pinner. They ensure correct placement and orientation of the components on a PCB. This, in turn, maintains quality and reliability for electronic devices in a range of industries. Without a Pinner’s precision and attention to detail, chances of error and defects increase in the final product dramatically.

Other than the effects the Pinner has on quality, this is an equally important function in the enhancement of the manufacturing process; it cuts costs and aids scale-up. As demand continues to increase for electronics products, so will the work of the PCB Pinner. It is only a matter of time before technology demands such high-quality reliability from its products that manufacturers will remain at the forefront with expertly manufactured PCBs. Therefore, the job of a PCB Pinner is important not merely in itself but it is irreplaceable within the production of any kind of PCB.

Latest Blog

Table of Content

Contcat Us

Phone: +86-18123905375

Email: sales@circuitcardassembly.com

Skype: ali_youte

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Afrikaans

Afrikaans Shqip

Shqip አማርኛ

አማርኛ العربية

العربية Հայերեն

Հայերեն Azərbaycan dili

Azərbaycan dili Euskara

Euskara Беларуская мова

Беларуская мова বাংলা

বাংলা Bosanski

Bosanski Български

Български Català

Català Cebuano

Cebuano Chichewa

Chichewa 简体中文

简体中文 繁體中文

繁體中文 Corsu

Corsu Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Esperanto

Esperanto Eesti

Eesti Filipino

Filipino Suomi

Suomi Français

Français Frysk

Frysk Galego

Galego ქართული

ქართული Deutsch

Deutsch Ελληνικά

Ελληνικά ગુજરાતી

ગુજરાતી Kreyol ayisyen

Kreyol ayisyen Harshen Hausa

Harshen Hausa Ōlelo Hawaiʻi

Ōlelo Hawaiʻi עִבְרִית

עִבְרִית हिन्दी

हिन्दी Hmong

Hmong Magyar

Magyar Íslenska

Íslenska Igbo

Igbo Bahasa Indonesia

Bahasa Indonesia Gaeilge

Gaeilge Italiano

Italiano 日本語

日本語 Basa Jawa

Basa Jawa ಕನ್ನಡ

ಕನ್ನಡ Қазақ тілі

Қазақ тілі ភាសាខ្មែរ

ភាសាខ្មែរ 한국어

한국어 كوردی

كوردی Кыргызча

Кыргызча ພາສາລາວ

ພາສາລາວ Latin

Latin Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba Lëtzebuergesch

Lëtzebuergesch Македонски јазик

Македонски јазик Malagasy

Malagasy Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം Maltese

Maltese Te Reo Māori

Te Reo Māori मराठी

मराठी Монгол

Монгол ဗမာစာ

ဗမာစာ नेपाली

नेपाली Norsk bokmål

Norsk bokmål پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português ਪੰਜਾਬੀ

ਪੰਜਾਬੀ Română

Română Русский

Русский Samoan

Samoan Gàidhlig

Gàidhlig Српски језик

Српски језик Sesotho

Sesotho Shona

Shona سنڌي

سنڌي සිංහල

සිංහල Slovenčina

Slovenčina Slovenščina

Slovenščina Afsoomaali

Afsoomaali Español

Español Basa Sunda

Basa Sunda Kiswahili

Kiswahili Svenska

Svenska Тоҷикӣ

Тоҷикӣ தமிழ்

தமிழ் తెలుగు

తెలుగు ไทย

ไทย Türkçe

Türkçe Українська

Українська اردو

اردو O‘zbekcha

O‘zbekcha Tiếng Việt

Tiếng Việt Cymraeg

Cymraeg isiXhosa

isiXhosa יידיש

יידיש Yorùbá

Yorùbá Zulu

Zulu