Why Prototype PCBs Are Crucial for Design Validation

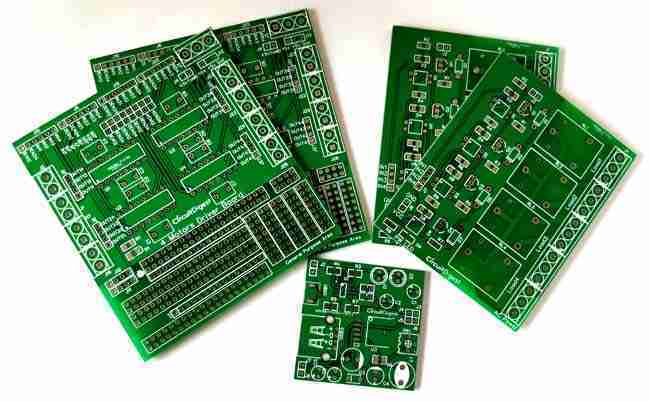

In the world of electronics, fast development and advancement depend intensely on productive testing and approval forms. A pivotal step in the Design and improvement of electronic gadgets is the utilize of PCB Prototypes. These early-stage circuit boards, frequently alluded to as Proto PCB, empower engineers to survey, refine, and approve their Designs some time recently mass generation. By leveraging prototype PCBs, companies can minimize blunders, move forward usefulness, and optimize generation efficiency.

Prototyping makes a difference distinguish Design blemishes early when rectifications are generally reasonable. Issues found amid the prototype stage might incorporate inaccurate impressions, insufficient clearances, warm hotspots, or flag judgment issues that weren’t clear in computerized Prototypes. Catching these issues some time recently generation spares considerable time and resources.

For complex Designs, iterative prototyping gives important learning openings. Each adaptation builds upon lessons from past emphases, refining the Design incrementally. This approach is especially important for novel or challenging applications where ideal arrangements aren’t instantly obvious.

This Content investigates the significance of PCB Prototypes, their part in Design approval, and how they contribute to the by and large victory of electronic products.

What is a PCB Prototype?

A PCB Prototype is an early form of a printed circuit board utilized to test a Design some time recently full-scale generation. It is made to assess circuit execution, recognize blunders, and guarantee all components work as aiming. Proto PCBs permit originators to troubleshoot issues, refine formats, and actualize fundamental changes some time recently committing to large-scale manufacturing.

Types of PCB Prototypes

1. Visual Prototype: Utilized to evaluate the format and fit of components without full electrical functionality.

2. Proof-of-Concept Prototype: Illustrates the principal working rule of the design.

3. Functional Prototype: A completely working PCB that mirrors the last product.

4. Pre-Production Prototype: A about last form utilized to test generation feasibility.

Each sort serves a distinctive reason in the Design and advancement cycle, guaranteeing that items meet quality and execution measures some time recently coming to the market.

Importance of PCB Prototypes in Design Validation

1. Early Location of Design Flaws

One of the essential reasons for utilizing PCB Prototypes is to recognize Design blemishes early in the advancement prepare. By testing a Proto PCB, engineers can distinguish issues such as:

● Incorrect component placement

● Signal interference

● Power conveyance problems

● Short circuits and fastening errors

Early discovery diminishes expensive modifications and anticipates imperfect items from entering the market.

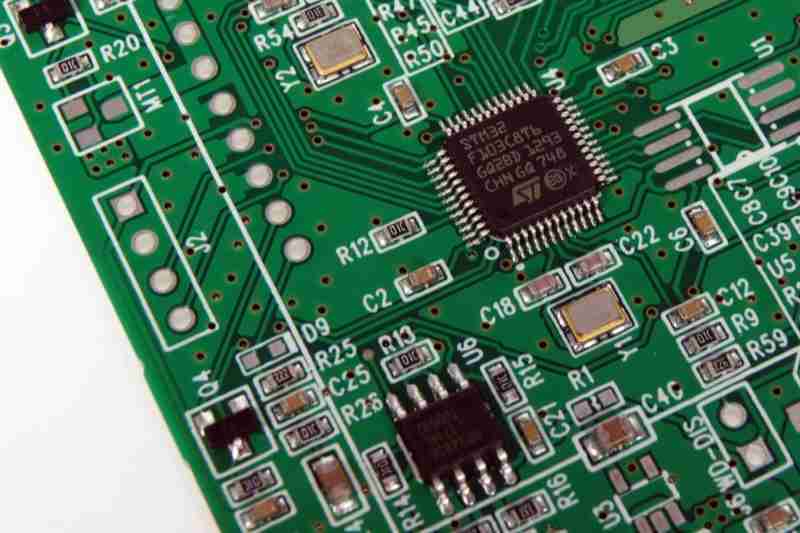

2. Useful Testing and Execution Evaluation

A PCB prototype permits architects to confirm whether their circuits work as aiming. By physically testing a Proto PCB, engineers can degree electrical parameters, evaluate warm execution, and guarantee that the board meets its Designning determinations. This step is vital in businesses such as therapeutic gadgets, aviation, and car electronics, where unwavering quality is non-negotiable.

3. Fetched and Time Efficiency

Developing a PCB without prototyping can result in costly blunders that may require critical overhauls. Proto PCBs decrease the chance of fabricating flawed items, eventually sparing costs on:

● Component reordering

● Assembly line adjustments

● Post-production troubleshooting

Additionally, testing Prototypes makes a difference quicken the Design prepare by permitting for quicker cycles and refinements.

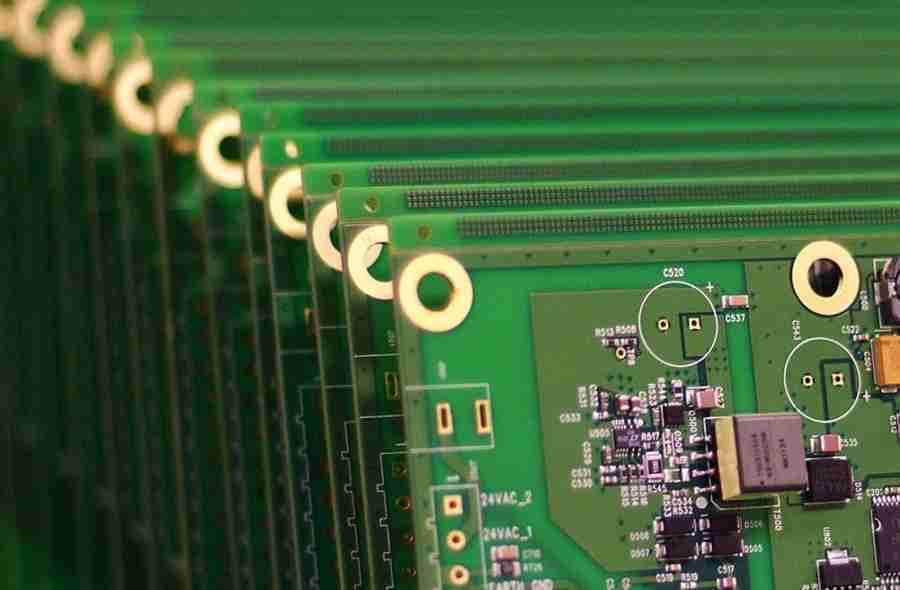

4. Optimizing Fabricating Processes

Prototyping makes a difference recognize potential fabricating challenges early on. This incorporates assessing:

● Component compatibility

● Soldering techniques

● Heat dissemination efficiency

● Signal astuteness and EMI interference

By tending to these issues in the PCB prototype stage, producers can streamline generation, guaranteeing effectiveness and consistency in mass production.

5. Improving Item Unwavering quality and Safety

Product unwavering quality is basic, particularly in high-risk businesses such as therapeutic gadgets and aviation. Proto PCBs permit for thorough testing beneath different conditions, guaranteeing that the last Design works securely and reliably. Natural push tests, warm cycling, and vibration tests can be conducted on Prototypes to ensure strength and reliability.

6. Compliance with Industry Standards

Regulatory compliance is an fundamental angle of PCB Design, particularly for items that must follow to worldwide security and execution guidelines (e.g., ISO, IPC, UL certifications). Utilizing PCB Prototypes, engineers can affirm that the Design meets industry prerequisites some time recently mass generation, dodging legitimate and compliance issues down the line.

How to Optimize PCB Prototyping for Way better Design Validation

1. Select the Right Materials

Selecting suitable PCB materials is pivotal for precise prototyping. Consider components such as:

● Thermal conductivity

● Dielectric constant

● Signal loss

● Mechanical durability

2. Utilize Progressed Simulation Tools

Before manufacturing a Proto PCB, utilizing Simulation computer program like Altium Creator, Falcon, or KiCad can offer assistance in anticipating circuit behavior and minimizing Design errors.

3. Perform Careful Testing

Key tests for PCB Prototypes include:

● Functional testing (guaranteeing all components work as expected)

● Signal astuteness testing (checking for clamor and interference)

● Thermal examination (surveying warm scattering efficiency)

4. Repeat and Improve

The reason of Proto PCBs is to permit iterative changes. After introductory testing, refine the Design, alter component arrangement, and make vital changes some time recently last production.

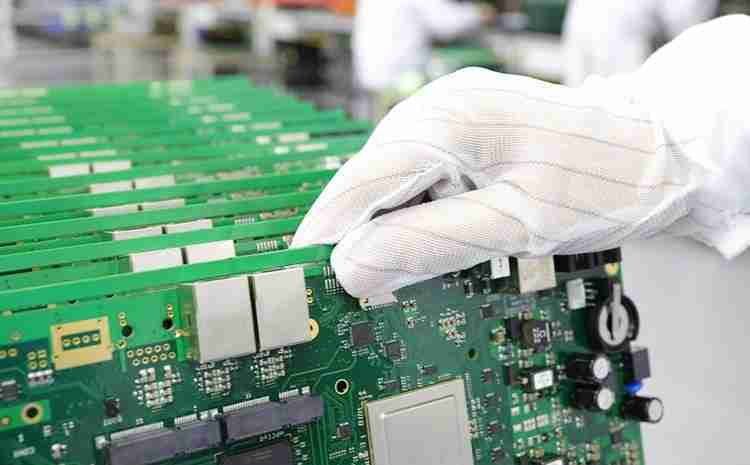

5. Collaborate with PCB Creation Experts

Working with experienced PCB producers guarantees high-quality Prototypes with exact manufacture and gathering. Select accomplices with mastery in quick prototyping and small-batch production.

Real-World Applications of PCB Prototypes

Consumer Electronics

Smartphone, tablets, and wearable depend on PCB Prototypes to test compact, high-density circuit Designs some time recently mass production.

Automotive Industry

Modern vehicles join progressed PCBs for route, amusement, and security frameworks. Proto PCBs offer assistance approve Designs some time recently joining them into generation vehicles.

Medical Devices

Life-saving electronics like pacemakers and demonstrative instruments experience thorough prototyping to guarantee compliance with therapeutic controls and operational reliability.

Aerospace and Defence

PCBs utilized in satellites, air ship, and military applications require broad testing beneath extraordinary conditions, making PCB Prototypes vital in the advancement phase.

Conclusion

The significance of PCB Prototypes in Design approval cannot be exaggerated. They serve as an fundamental device for recognizing blunders, optimizing usefulness, guaranteeing compliance, and streamlining the fabricating handle. Without Proto PCBs, companies hazard expensive corrections, item disappointments, and administrative setbacks.

By contributing in legitimate PCB prototyping, businesses can create high-quality, dependable, and proficient electronic items, eventually driving to way better advertise victory and client fulfilment.

Latest Blog

Table of Content

Contcat Us

Phone: +86-18123905375

Email: sales@circuitcardassembly.com

Skype: ali_youte

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Afrikaans

Afrikaans Shqip

Shqip አማርኛ

አማርኛ العربية

العربية Հայերեն

Հայերեն Azərbaycan dili

Azərbaycan dili Euskara

Euskara Беларуская мова

Беларуская мова বাংলা

বাংলা Bosanski

Bosanski Български

Български Català

Català Cebuano

Cebuano Chichewa

Chichewa 简体中文

简体中文 繁體中文

繁體中文 Corsu

Corsu Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Esperanto

Esperanto Eesti

Eesti Filipino

Filipino Suomi

Suomi Français

Français Frysk

Frysk Galego

Galego ქართული

ქართული Deutsch

Deutsch Ελληνικά

Ελληνικά ગુજરાતી

ગુજરાતી Kreyol ayisyen

Kreyol ayisyen Harshen Hausa

Harshen Hausa Ōlelo Hawaiʻi

Ōlelo Hawaiʻi עִבְרִית

עִבְרִית हिन्दी

हिन्दी Hmong

Hmong Magyar

Magyar Íslenska

Íslenska Igbo

Igbo Bahasa Indonesia

Bahasa Indonesia Gaeilge

Gaeilge Italiano

Italiano 日本語

日本語 Basa Jawa

Basa Jawa ಕನ್ನಡ

ಕನ್ನಡ Қазақ тілі

Қазақ тілі ភាសាខ្មែរ

ភាសាខ្មែរ 한국어

한국어 كوردی

كوردی Кыргызча

Кыргызча ພາສາລາວ

ພາສາລາວ Latin

Latin Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba Lëtzebuergesch

Lëtzebuergesch Македонски јазик

Македонски јазик Malagasy

Malagasy Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം Maltese

Maltese Te Reo Māori

Te Reo Māori मराठी

मराठी Монгол

Монгол ဗမာစာ

ဗမာစာ नेपाली

नेपाली Norsk bokmål

Norsk bokmål پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português ਪੰਜਾਬੀ

ਪੰਜਾਬੀ Română

Română Русский

Русский Samoan

Samoan Gàidhlig

Gàidhlig Српски језик

Српски језик Sesotho

Sesotho Shona

Shona سنڌي

سنڌي සිංහල

සිංහල Slovenčina

Slovenčina Slovenščina

Slovenščina Afsoomaali

Afsoomaali Español

Español Basa Sunda

Basa Sunda Kiswahili

Kiswahili Svenska

Svenska Тоҷикӣ

Тоҷикӣ தமிழ்

தமிழ் తెలుగు

తెలుగు ไทย

ไทย Türkçe

Türkçe Українська

Українська اردو

اردو O‘zbekcha

O‘zbekcha Tiếng Việt

Tiếng Việt Cymraeg

Cymraeg isiXhosa

isiXhosa יידיש

יידיש Yorùbá

Yorùbá Zulu

Zulu