In the fast-paced world of electronics, where compact and solid plans are progressively in request, Surface Mount PCB (Printed Circuit Board) Technology has developed as the gold standard. SMT PCB Boards, brief for Surface Mount Technology Printed Circuit Boards, have revolutionized how electronic electronics are planned and made. Their capacity to back miniaturization without compromising unwavering quality makes them the favoured choice for cutting edge electronic applications.

This Content investigates why SMT PCB Boards are the go-to arrangement for compact and dependable plans, highlighting their preferences and clarifying their basic part in forming the future of electronics.

What is an SMT PCB Board?

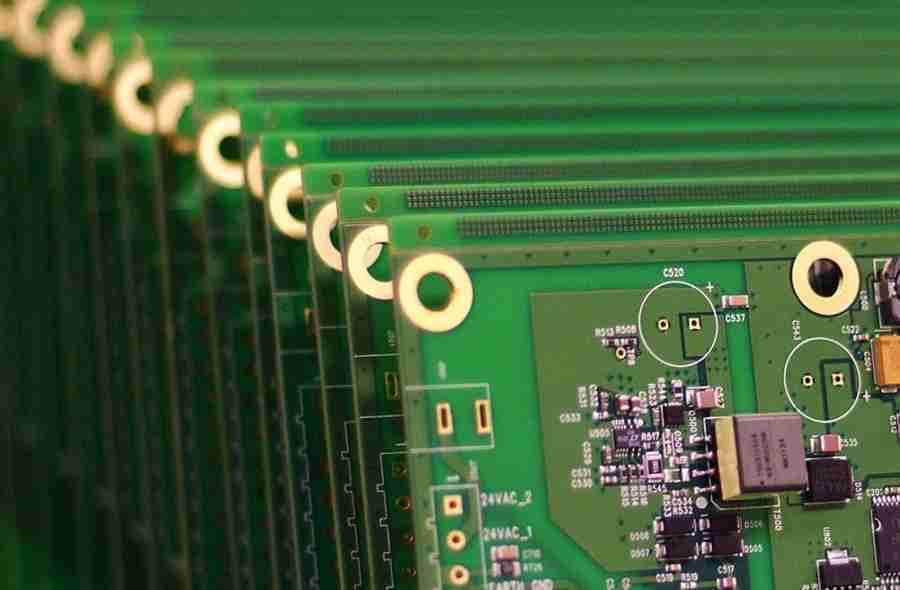

Before plunging into their focal points, it’s critical to get it what an SMT PCB board is. SMT (Surface Mount Technology) is a strategy of assembly electronic components onto a PCB by straightforwardly mounting them on the surface of the board. Not at all like conventional through-hole Technology, where components are embedded into penetrated gaps and patched on the inverse side, SMT disposes of the require for such gaps. Instep, components are fastened straightforwardly onto the surface, permitting for a more streamlined and compact design.

Surface Mount PCBs are broadly utilized in different businesses, counting customer hardware, car, therapeutic electronics, broadcast communications, and mechanical apparatus. They have ended up the spine of cutting edge electronic electronics, from savvy phones and portable workstations to car control frameworks and IoT (Internet of Things) devices.

Why Surface Mount PCBs Are Perfect for Compact Designs

One of the essential reasons Surface Mount PCBs are favoured is their capacity to bolster compact plans. Here’s how they accomplish this:

1. Miniaturization of Components

SMT PCB Boards utilize surface-mount components (SMDs), which are altogether littler than their through-hole partners. These components can be set closer together on the board, diminishing the generally measure of the PCB. This miniaturization is fundamental for electronics like shrewd phones, wearable, and other versatile contraptions that request little frame factors.

For case, cutting edge savvy phones depend on SMT PCBs to fit high-performance processors, memory chips, and sensors into a thin and lightweight plan. Without the compact nature of SMT Technology, such levels of integration would be impossible.

2. Higher Component Density

Surface Mount PCBs can suit a higher number of components per unit region compared to conventional PCBs. By mounting components on both sides of the board, creators can assist maximize the accessible space. This tall component thickness is basic for progressed electronics with complex circuitry, such as restorative demonstrative hardware and mechanical mechanization systems.

3. End of Bored Holes

Through-hole Technology requires bored gaps for each component lead, which takes up profitable space on the board. SMT kills the require for these gaps, liberating up extra genuine bequest for components and circuitry. This permits architects to make more compact and effective layouts.

4. Flexible Plan Options

SMT PCB Boards offer more noteworthy plan adaptability. Since components are mounted on the surface, architects can test with different formats, making special and optimized plans custom-made to particular applications. This adaptability is particularly critical in businesses like aviation and mechanical autonomy, where space limitations and execution requests are critical.

Why Surface Mount PCBs Are Dependable for Advanced Electronics

Reliability is another key figure that makes SMT PCB Boards the go-to choice for electronic electronics. Here’s why they exceed expectations in this area:

1. Progressed Electrical Performance

Surface Mount PCBs offer prevalent electrical execution due to shorter lead lengths and decreased parasitic inductance and capacitance. This leads to speedier flag transmission and lower flag twisting, making SMT PCBs perfect for high-frequency and high-speed applications.

For occasion, broadcast communications hardware and information centres depend on SMT PCBs to handle high-speed information handling and transmission with negligible flag loss.

2. Improved Mechanical Strength

SMDs are patched straightforwardly onto the PCB surface, giving way better mechanical soundness compared to through-hole components. This coordinate association diminishes the chance of components getting to be free or unstuck due to vibrations, stuns, or warm push. As a result, Surface Mount PCBs are well-suited for applications in unforgiving situations, such as car frameworks, aviation hardware, and mechanical machinery.

3. Less Absconds and Failures

The automation of SMT assembly forms guarantees a higher level of accuracy and consistency compared to manual through-hole assembly. This diminishes the probability of abandons, such as fastening mistakes or misaligned components. Also, SMT PCBs experience thorough testing amid generation to guarantee their unwavering quality and performance.

4. Warm Management

Compact and high-density plans frequently produce noteworthy warm, which can influence the unwavering quality of electronic electronics. SMT PCB Boards address this challenge by joining proficient warm administration methods, such as warm sinks, warm vias, and specialized materials. This makes a difference keep up ideal working temperatures and avoids overheating.

Advantages of Surface Mount PCBs in Key Industries

The compactness and unwavering quality of SMT PCB Boards make them irreplaceable in different businesses. Here’s how they are utilized in distinctive sectors:

1. Consumer Electronics

Surface Mount PCBs are at the heart of shopper hardware, counting savvy phones, tablets, portable workstations, and savvy observes. Their little estimate, lightweight development, and capacity to handle complex circuits make them perfect for these applications. The unwavering quality of SMT PCBs guarantees that these electronics work reliably, indeed with day by day wear and tear.

2. Automotive Industry

Modern vehicles are prepared with progressed electronic frameworks, such as engine control units (ECUs), infotainment frameworks, and advanced driver-assistance systems (ADAS). SMT PCB Boards are basic for these frameworks, as they offer the unwavering quality required to withstand vibrations, temperature variances, and other unforgiving conditions experienced in car environments.

3. Restorative Devices

In the therapeutic field, exactness and unwavering quality are fundamental. SMT PCBs are utilized in therapeutic electronics such as pacemakers, demonstrative hardware, and convenient screens. Their compact plan permits these electronics to be lightweight and versatile, whereas their unwavering quality guarantees precise and reliable performance.

4. Telecommunications

The broadcast communications industry depends on SMT PCBs for high-speed organizing hardware, such as switches, switches, and base stations. These PCBs empower quick information handling and flag transmission, guaranteeing dependable network for millions of users.

5. Mechanical Automation

SMT PCB Boards are utilized in mechanical mechanization frameworks, such as mechanical technology, sensors, and controllers. Their capacity to handle complex circuits in a compact and solid frame makes them perfect for requesting mechanical environments.

How to Optimize SMT PCB Designs

To completely use the benefits of SMT PCB Boards, it’s imperative to take after best hones amid the plan and fabricating prepare. Here are a few tips for optimizing SMT PCB designs:

1. Choose the Right Components: Select surface-mount components that meet the particular prerequisites of your application, such as measure, control utilization, and performance.

2. Optimize Format and Arrangement: Carefully arrange the format of components to maximize space productivity and guarantee legitimate flag integrity.

3. Implement Compelling Warm Administration: Utilize procedures like warm sinks, warm vias, and legitimate dispersing to oversee warm dissemination effectively.

4. Automate Assembly Forms: Use computerized SMT get together gear to guarantee exactness and consistency amid manufacturing.

5. Conduct Thorough Testing: Perform intensive testing to distinguish and address potential absconds, guaranteeing the unwavering quality of the last product.

Conclusion

Surface Mount PCBs have gotten to be the go-to choice for compact and solid plans in cutting edge hardware. Their capacity to bolster miniaturization, upgrade electrical execution, and withstand cruel conditions makes them crucial over different businesses. From customer electronics and car frameworks to therapeutic electronics and broadcast communications, SMT PCB Boards are forming the future of technology.

As the request for littler, more productive, and dependable electronic electronics proceeds to develop, Surface Mount PCBs will stay at the cutting edge of advancement, driving progressions in plan and usefulness. Whether you’re creating the next-generation Smartphone or a cutting-edge restorative gadget, SMT PCB Boards are the key to accomplishing compact and solid arrangements.